Search the Community

Showing results for tags 'wrench'.

-

I just made my second attempt at an oil change on my trike. Attempt #1: Bought an oil filter, oil and and oil filter wrench. The filter wrench when attached to the socket wrench will not fit onto the filter. There simply is not enough room between the oil filter and the radiator housing. Since I had already drained the oil, I went to get another filter wrench that would work with an open or boxed end wrench. The only filter wrenches were made of plastic. PLASTIC!! The OReilly guy assured me it was designed to withstand the pressure of the wrench on the nut. It failed miserably! Since I could not get the oil filter off. I elected to simply replace the oil and try again later. Attempt # 2: I bought more oil and three of my friends assured me that the oil filter can be easily removed with a pair of large channel locks. It probably can, but there is no room between the carport floor and the filter to allow the placement of the channel locks!. Can someone with a trike explain to me how on earth do I get that #%$#&^ oil filter off! Am I supposed to forever take it to a dealer for a $78 oil change?

-

Dano knows what this is for.....

-

I've been trying to get the screw under the trunk latch of my I/S out, the sumbich ain't moving! Tried the regular screw driver, didn't work. Tried heating the nut beforehand, didn't work. Tried grinding a bigger slot in the head so i could get a BMF screwdriver in there, no luck. Tried grinding the sides of the screw down so I could get a wrench on there, didn't work either. Seems like that thing is welded in there http://www.valkyrieforum.com/bbs/Smileys/actions/tickedoff.gif http://www.valkyrieforum.com/bbs/Smileys/actions/tickedoff.gifhttp://www.valkyrieforum.com/bbs/Smileys/actions/tickedoff.gif So how do I get this POS out of there short of grinding the whole head down? Thanks,

-

The other day my son came home and when he parked the car he heard a tire going down. The next day I took off the tire and while rolling it to the pickup I could hear something inside the tire. The tire was cut and ruined, and while changing the tire we pulled out a yamaha combination #8 and #10 wrench. So if you were riding by my place spying on me, you can stop and get your wrench back!!!! I've seen lots of different stuff in tires, but never a wrench.

-

The Dealer says I need steering head bearings which is over 4 hours labour at $85 per hour plus the kit. The bike only has 65,000 so I"m wondering if perhaps they are just loose. I'm going to look into that this afternoon. But if I need some work on it........I've got Dingy's wrench But I need a "how to". I found a tutorial for 2nd Gen by Freebird...but couldn't find anything on a 1st Gen (mkII) ....could anyone let me know if there is a how to on REPLACING or Greasing the steering bearings?

-

I have been wanting to change the spark plugs on my VR. Discovered my 18 mm deep socket would not fit in the hole. Spent most of the day browsing through the local tool shops looking for a thin walled socket without success. At the end of it all went to the dealer to see what they had with interesting results. Found out the plug socket only came with the original tool kit. Yamaha wanted... wait for the drum roll... $539.00 ... Whoo-Hoo On the other hand, they did have a Honda plug wrench for sale as a stand alone tool. Went out to see if it would fit and while rummaging around for a screwdriver to remove the side grill found that I had the OEM plug wrench already, just didn't know it. The Honda plug wrench did fit. Perhaps unfortunately, in my excitement I forgot to get the price of the Honda tool. It likely was not very expensive as it was zinc plated and not chromed like my POSH Royale tool. Thought I would pass that along just in case anyone else really was stuck without a way to remove their plugs.

-

Looks like I ended up with an extra torque wrench. It is in a red case. PM me with your address if it is yours and I'll get it mailed.

-

I posted last week about the creaking noise coming from the rear. My option was to get it done on warranty or do it myself. Not sure of myself I printed the info from the tech section and tackled it myself. Not a bad job and it will be easier next time. It took me a couple of hours but it is 60 miles to the dealer so that would mean two trips and four hours on the road. I will finish up tomorrow night in about 15 minutes. My torque wrench only goes to 75 lbs and the axle calls for 140 lbs. Any ideas short of buying another wrench. Thanks to those who take pictures and help with the tech forum! I love this site!

-

OK, I have done a search, but did not find the directions for REPLACING my clutch and brake levers. I just ordered a new set...chrome with leather braiding from Ironbraid.com. But the posts I found mostly discussed where to get them at online. My question...can someone explain how to change them out in PLAIN LANGUAGE. My wrench skills are weak...but I'm willing to try. Will I have to remove any cables? Is this a difficult swap to do? Thanks, Wally

-

Guys, Thank you, thank you, thank you for all your kind help on my quest to figure out, A) how to split my faring, B) How to take off the hex bolts holding my Yamaha driving light bar inplace c) Which connector is the audio control connector. I'm also color blind if things aren't confusing enough. So has this ever happened to any of you? Today I decided to split my faring and clean fix, whatever you want to call it; the main audio control unit connector because I am having the same issues that others have been having. Sooooooooooooooooooo I got the faring split. That was OK. But then I could not figure how to get the light bar mount off. I realized I had to get what I thought was a 5.5mm ball hex allan wrench. So I made a list. On my list I put two things you good folks told me I needed. A ball hex wrench some dielectric grease. I spent two hours driving around the city looking in numerous auto parts stores for a simple 5.5mm hex allan wrench. I finally found one in a set at the fourth parts store I stopped in. What the heck, for 12 bucks I bought the set. I was ecstatic and couldn't wait to get home to loosen and remove those wretched hex bolts. Guess what I forgot to buy even though I had the list gripped so tight in my sweaty palms that the paper got wet and began to fall apart? You got it - dielectric grease. I can't believe it. I do have some 12/24 contact cleaner however and I am going to spray the heck out of every connector. Here is my quandary. Should I wait until tomorrow and go buy some dielectric grease or simply spray everything with the 12/24 cleaner and put it back together. AAAARRRRrrrrggggggggghhhhhhhhhhhhhhh? Please, please tell me some of you have had this same experience. Chris in Red Deer, Alberta

- 18 replies

-

- connector

- dielectric

-

(and 3 more)

Tagged with:

-

ok i have a 2005 pontiac grandprix i had new tires installed about 3 weeks ago. now my front end shakes while braking? are the darn rotors warped? it goes shaky shaky and the whole steerring shakes.? while brakeing? im not sure if these new type rotors can be turned down like i use to back in the 70,s and 80,s. also could the shop have done this by useing a impact wrench? seems like you should just snug them and tork them like the old days and do it in a pattern? i know im old school shade tree mecahnic from the old days when a cresent wrench screwdriver ductape and a few choice #### words could keep it running but these new cars are way beyond my old school knowledge.

-

I looked into listing my Steering Ring Nut Wrench on Amazon and it appears I have to be a Professional Seller in order to do it. This is because there is no other listing for the wrench currently on Amazon that I could find. A regular seller does not appear to be able to create a new item. Is this accurate? Professional Seller is $39.99 a month. I don't think it would be worth that to me to list them on there. Any way around this? Gary

-

Trying To Fill Differential

GaryZ posted a topic in Venture and Venture Royale Tech Talk ('83 - '93)

OK guys, I have drained the differential and calculated that the refill is 300cc or 10oz (.3L per the manual). My problem is the fill plug doesn't want to come loose. It appears to be a 6mm female hex head and my allen wrench only wants to twist. I have soaked it in penetrating oil for now . . . Any ideas?- 9 replies

-

- allen

- differential

-

(and 3 more)

Tagged with:

-

Looking for a little info for the 600mi service. . . I will be on the road back home, 600 miles into the 2100 mile trip, and will of course need to do an oil and filter change, and rear-end oil change, my question is what size wrenches do I need for the oil drain plug, and rear diff drain and fill. It takes the same filter as my zx14 so the filter wrench and wratchet isn't a problem, and i need to carry as few as possible on my flight. Thanks in advance for helping. cs..

-

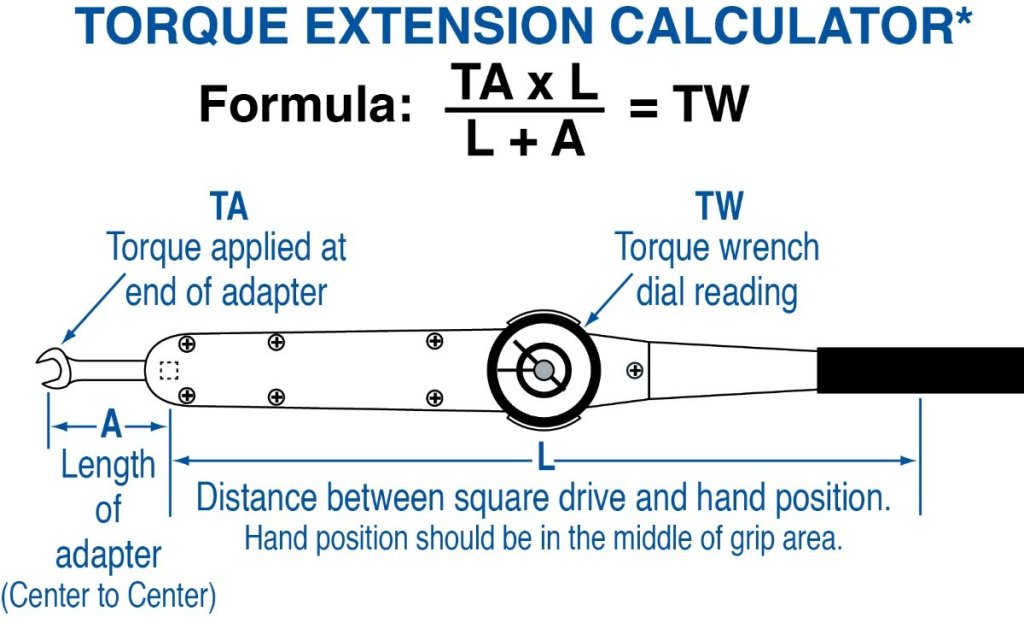

Submitted by Saddlebum. Proper use of steering head wrench with torque wrench By the way everyone for some of you who may not be aware of this, There is a small issue you need to keep in mind when using this tool with a torque wrench. If you mount the tool on on a torque wrench at a 90 degree angle to the torque wrench . You may set the torque wrench to the exact torque spec. If you mount it at a 45 DEG. angle or straiaght in line. You have to do a small calculation to compansate for the additional length. In otherwords you set your torque wrench at a lower setting to compensate for the added length. Here are two links that will do the calculation for you as well as explain it. The second link actually gives you a pic of the torgue wrench setup. you simply fill in the boxes and it will tell you what set your torque wrench at in order to reach the desired torque. https://belknaptools.com/extensions-calculator/

-

February 12, 2010 post date I have received my order of the steering head bearing nut wrench. I will be shipping out to every one that has ordered one. I have extras, so if you would like one and have not ordered, see below for info. I have include a PDF cut from the 1st Gen & RSV service manuals relating to the procedure to set torque. Pay attention to text about setting torque wrench at a 90 degree angle to wrench. Not doing so will affect torque reading. Also listed below are the threads relating to this tool. Gary http://www.venturerider.org/forum/showthread.php?t=45046 http://www.venturerider.org/forum/showthread.php?t=44833 http://www.venturerider.org/forum/showthread.php?t=44719 http://www.venturerider.org/forum/showthread.php?t=44668&highlight=steering+head http://i1007.photobucket.com/albums/af193/gdingy101/PICT5202.jpg The procedure for setting steering head torque is outlined in the service manuals beginning with the 1986 manual. This is under Periodic Inspection & Adjustment - Chassis - Steering Head Adjustment. Also, if you are the proud owner of the MKI (83-85) Ventures, you could use the procedure outlined in the 86-93 manual. If you need a copy of this procedure I can provide it for you. The tool will work on any year Venture. The same part number is shown in the part fiche from 1983 through the RSV's for the steering head bearing nut. The tool will also work on 1st gen VMaxs & FJR's The tool is laser cut from 1/4" thick, 304 stainless steel. I can supply this tool at a cost of $23.00 including first class shipping to lower 48 US, Canada will be $24.00, first class shipping. I can order more at any time. If you would like to order one or more my paypal address is gary@dinges.com. I will see the paypal transaction in my email. I can also accept check or money orders. PM me for address. Please mark payment as a personal transaction. Paypal does not send your address to me when it is marked a gift. Please include shipping address & your screen name in Paypal transaction, comments field. Attached are pictures showing the finished tool. Gary

-

Ran some errands on the RSV yesterday. Out of the blue, "the light came on" darn this thing is sure is shifting "clunky". Well it does have 5500 miles on the T6 Rotella. I wondered how long it would run, cause it was not very discolored. Changed (stayed with the T6) it this afternoon, sprayed dry-lube on the linkage and man, all the difference in the world!!! BTW If you use the PL14610 instead of the PL14612 you gonna need a filter wrench like the on the on the bottom (or the kind that look like big jaw pliers). The longer "610" fits fine, but comes too close to a frame rail to use a wrench like the one on the upper left.

- 17 replies

-

- difference

- filter

-

(and 3 more)

Tagged with:

-

A few out of the dozens of water temp gauge installations have reported leakage at the adapter. I think we have found a cure. I sell the adapters with a 18mm crush washer. The problem occurs where the inside diameter of the washer meets the outside diameter of the adapter. There is a recess machined into the adapter which allows the washer to slide over to one side which will not seal. http://i672.photobucket.com/albums/vv87/dawarren77377/Bike%20shots/waterseal3.jpg?t=1263574491 To solve this issue place a 1/2" ID X 3/32" thick o'ring between the adapter and the crush washer. Make sure the tabs on the washer face away from the o'ring. With the o'ring in place against the washer, the tabs should still engage the threads. http://i672.photobucket.com/albums/vv87/dawarren77377/Bike%20shots/waterseal4.jpg?t=1263574679 http://i672.photobucket.com/albums/vv87/dawarren77377/Bike%20shots/waterseal5.jpg?t=1263574858 http://i672.photobucket.com/albums/vv87/dawarren77377/Bike%20shots/waterseal6.jpg?t=1263574887 The o'ring alone would work if the adapter had a groove machined in it to prevent the o'ring from squishing out (like the water jacket plug removed from the cylinder head). The washer holds the o'ring in place and the o'ring holds the washer centered. http://i672.photobucket.com/albums/vv87/dawarren77377/Bike%20shots/waterseal7.jpg?t=1263574917 The o'ring is available at most hardware/home improvement stores. The one I bought was a #35 o'ring, however all o'ring manufacturers may not use the same number. If anyone who has bought a kit from me needs either the crush washer or the o'ring, let me know. Also, I have received a request to announce what tools I use to remove the water jacket plug and install the adapter. Most use a standard 10mm "L" or Allen style wrench for removal. A 10mm hex bit/adapter to 3/8" drive works well for plug removal. You can put a breaker bar on the hex tool for leverage. I sawed one inch off of a 10mm "L" wrench which I can use a 10mm box wrench or a socket and ratchet. It is important to use a hex that is in good shape. If a rounded hex tool is used and the plugs is damaged, you have problems. I use a 7/8" or 22mm socket with ratchet to install the adapter. If I have a leak or need to tweak the adapter after it is installed, I use a tubing wrench. You don't have to buy an expensive tubing wrench. I bought a $3.00 combination wrench at a pawn shop and ground a 1/4" slot in the box end. This slides over the thermocouple tube easily. I also use a 5/8" (16mm) tubing wrench for the thermocouple nut. Cheers, Ponch

-

I am trying to do the steering head adjustment but I cannot for the life of me get that top nut loose. I've tried channel locks, even clamped on locking pliers and hammered the end, tried putting a pipe on the end .... all no go. That is one tight nut. Any suggestions .... I dont have a wrench big enough for the head, and the darn space is so small. I presume it isnt a reverse thread and its "lefty lucy". Aaaargh!

-

I didn't have anything to do this afternoon so I thought I would tackle the HD Clutch Spring Kit.... I was almost wrapped up, snapping pictures the whole way when I snapped one of the 6 bolts off that holds the spring on......... OK so I was using a torque wrench that starts at 10lbs.. So I backed it off to about where I thought 5lbs would be (Note: Don't do this)..... I'm a big O dummy!! As I am tightening the bolts I am thinking these are not getting tight, so I started backing them out when one snapped off . These bolts must be crazy soft, because I didn't feel like I was over torquing them . Providing I can get this one out :/, I am replacing all six bolts and buying a torque wrench that measures inch lbs. Couple of questions- Should I use loctite ? As I said before it doesn't seem like they were very tight at all... Do you think I weakened the new spring?

-

Just in case anybody missed it in the General Tech Talk area, Dingy is now taking orders for his fork wrench. It looks to have turned out very nice and I consider it a essential addition to your tool box. You really should check it out. http://www.venturerider.org/forum/showthread.php?p=434977#post434977

-

Would someone that has a Yamaha tool p/n YU-01268, ring nut wrench, and could measure a couple of things on it please PM me ? Picture of it is attached below. The RSV & the 86-93 Venture manuals shows this tool being used in the 'Periodic Inspections and Adjustment' section under 'Chassis - Steering Head'. I am looking at getting some of these made and need two measurements from the "official" tool. This tool allows the torque to be set on the steering head bearings without guessing at it. I have several contacts that have CNC laser and/or high definition plasma cutters that could make these. I want to get quotes on this item before I put it out there to see how much interest there would be in them. This tool should work on all 83-09 models. Gary

-

OK....I am getting ready to swap my two antennas out. I went out there and got ready to swap them out (should be easy right)...and now I see 3 wrench points (flat spots)... I tried very lightly to turn all 3, but I am afraid I might damage the antenna if I twist off the wrong one... So which one is it...the top smaller wrench point, the middle or the largest one being the lower one. Thanks, Wally

-

My dealer is close today and I can't call them.. After I did a walk around and all they gave me a owners manual and the paper work.. I was excited and ready to hit the road.. Also a Ign. key in a small bag with 2 small set screws and a allen wrench ..This is driving me crazy.. So where does this go? Please don't tell me this what holds the bike together...

-

Just changed my oil/filter, put the drain plug back in and, using my "trusty-dusty" Harbor Freight Torque Wrench, torqued the bolt to specification. The result?? I now have a stripped drain plug bolt/oil pan. After I fork out a pretty penny to fix this, I will NOT be using another Harbor Freight tool on my baby. ANy one else ever have an issue with an H.F. Torque Wrench?

(2).thumb.jpg.247ed202db256e2dabbcf27ca9d775d4.jpg)

.thumb.jpg.e030d8724ef3f2eadc94ab840d0f3801.jpg)