Search the Community

Showing results for tags 'wire'.

-

Moved this thread from the Watering Hole... Profiessional Input Please: I have read most of the threads regarding wiring of a Stebel Horn. I ordered one today so it will be on for a trip I am taking the end of May to Dragon/Cherohala area. I have decided to go with the "in cowling" mounting option. After reading Freebirds Tech article and others here on the forum I would like "confirmation" that I will be wiring it up correctly. 1. Mount horn vertically in cowling to frame. (Using pipe insulation to cushion per a suggestion on a thread and tie wraps) 2. Splice into hot wire from acc. plug and run wire to relay. ( Per Freebirds Tech article) (Increase size of fuse in lower fuse panel) 3. Wire from relay to horn positive. (Tech article) 4. Ground wire from horn to frame. ?????? 5. Splice into pink wire horn button and run wire to relay. (Threads tech article) What am I missing...anything. NOTE: I restored a 110 year old house here in Lynchburg. I did all restoration work "EXCEPT" electrical....Just not my thing..... Since I am under the cowling and want to keep the OEM horns active, do I need to deal with the "brown" wire everyone refers to in the mounting option on the lower right side of the bike?.... Long Tall in Lynchburg, VA

-

Can anyone tell me which wire coming rom the TCI module goes to which coil? I have determined that number one cylinder is the left rear, number two is left front, number three is right rear and four is right front. Now, there are four wires coming out of the TCI- Orange, Grey, Yellow and White that go to the coils. I need to know which wire goes to which cylinders perspective coil. Any help greatly appreciated! Tim

-

Ok, so I saw the thread in the library about the battery bypass. I found what I think is the right wire. It's right behind the battery bow, and is white with a red stripe. Problem is the actual sensor is not there, it's been unplugged from the wire. The plastic connector is on the wire, but the sensor wire is missing. So am I looking at the right wire? And if so, how do I bypass it from there with the sensor wire missing? Thanks for the help guys.

-

Have been slowly restoring an old 83 Venture recently purchased. It appears to have a nice accumulation of rust (sporry) on the frame and exposed bolts on the motor. Would appreciate advice on how to remove rust have been advised to use wire brush on drill and naval jelly but wondered if someone had better rust removal advice. Thanks James

-

I was wondering if anyone has figured out how to bluetooth their CB into a bluetooth intercom (Scala, Chatterbox, or the like)? I have heard you can do it but it will be a listen only. I want the full CB and think I figured out a way to do it. Just wondering if anyone has beaten me to it. I have good news and bad news. In theory this works, however I need to tweak it some. The problem I have run into is with the volume all the way up you can barley hear the cb. When you key up others can barley hear you. I think the problem lies within the size wires we used. I will tweak this in the up coming weeks. So far this is what I have done. Once again this is needs some tweaks. I wanted to be able to use my stock CB unit in conjunction with my Cardo Scala Rider G4 Power Set. It took me some time but I finally completed the task. I made this product for my Dad’s motorcycle (2007 Yamaha Royal Star Venture), but it should work on any intercom system using a standard 5 pin plug as they are wired the same. The Search: I started searching the internet for a solution to this problem and stumbled across this forum and read many people want this same feature. I think as of now the only option is from J&M and the system cost around $1,000USD! I have also seen where some people used store bought adapters (5 pin to 3.5mm adapter) and in doing so discovered they could only hear the CB. The wiring in the store bought adapters will not allow for a microphone input. The Idea: I located wiring diagrams of the stock 5 pin plug and a product called a Blue Tooth Adapter. The Blue Tooth Adapter (BTA from this point forward) I used is the Cardo BTA II (see link below). You can use other brands but be careful in your choice. The BTA is designed to plug into a non-bluetooth phone and allow the phone to connect to another bluetooth device, like a bluetooth ear mic (or in our case motorcycle blue tooth headset). Make sure you DO NOT buy one that is to transmit only! You will need the device to be capable of both transmitting and receiving. You will also need a 5 pin connecter plug (see link below). The Steps (Please if you are not good with wiring or soldering do not attempt this on your own) Once I had the two items I pulled the top of the BTA. Inside the device you will see a battery, a circuit board, and the coiled wire that has the 2.5mm plug attached to the other end. Three wires connect to the circuit board, on mine they were colored white, red and black. The wires were labeled: white is +microphone, the black is the common ground and the red is +speaker. Be sure to take note what color the wires are and what they do (they may be different for your application). With that taken care of you can reseal the unit. The next step was to cut the 2.5mm plug off the end of the wire. Take the bundled wire and strip off the insulating outer cover. This will reveal the 3 wires you noted in the previous step. Strip the insulation off the 3 wires so you have the bare wire exposed. Using the CB 5 pin wiring diagram (see link below) you may now solder the wires to the individual pins in the 5 pin connector plug. Make sure you solder the wires to their respective locations. In my case the white (microphone wire) will be soldered to the pin labeled 1 (see link below), the black (ground wire) is soldered to pins 4 and 2 (see link below) (this will ground the mic and speakers), and the red (speaker wire) is soldered to pins 5 and 3 (see link below) (this will allow you to hear the CB in both ears). Please if you are not good with wiring or soldering do not attempt this on your own. It takes some knowledge, quite a bit of soldering skill and some specialized tools. You have very little room to work and if not wired correctly it will not work properly. Also, if you use other parts or products other than I have I do not know for sure if they will work. I have not tested any other brand BTA’s or other brand headsets at this time. Thank you J. Yates CB 5 pin plug wiring diagram: http://venturers.org/Tech_Library/attachments/cbwiring.pdf 5 pin plug adapter http://www.frys.com/product/1570803?site=sr:SEARCH:MAIN_RSLT_PG Blue Tooth Adapter: [ame][url=http://www.amazon.com/gp/aw/d.html/ref=redir_mdp_mobile/191-4266561-3880738?a=B000LGUAU8]http://www.amazon.com/gp/aw/d.html/ref=redir_mdp_mobile/191-4266561-3880738?a=B000LGUAU8[/ame] I will update my next steps in days or weeks to come. Wish me luck. J. Yates

-

I need a source (auto parts store, amazon, etc) and a part number for a LED Flasher for my 1st gen bike. Do I need a 2 wire or 3 wire flasher? Where is the stock flasher located in the fairing? I read about a dual component flasher and a starter circuit unit that's combined into ONE unit together; then I read of a individual flasher; I'm just a little confused. Does my bike have the dual component or the single flasher? Thanks in advance.

-

Hey folks. I'm sorry if this has been asked previously and I can't find it - - - I need to wire up a couple of LED daylight running lights (DRLs) that I've mounted to the front of my Second Gen RSV. Obviously need to get at the low beam wire of the headlamp. Can somebody please tell me the quickest way of accessing same at the headlamp. I've printed out a wiring diagram for the bike, and from what I see I need the green wire. The owner's manual that came with the bike is next-to-useless. Tells me how to change a headlamp bulb, but that's about all. Hope y'all have a great 2015. Riding weather down-under is perfect. Warm days and 14 hours of daylight - gotta love that!

-

Ok, Trailer wiring question. I found an led stop turn strip. I put two smaller LED's at the top of the trailer as stop turns and hooked the center to running lights and was going to do stop then it dawned on me I was running a four wire system so they are stop turn. I am running a four wire system. Short of running another wire is there a way to grab the stop / turns from both sides, run it through some relays so I can get another center brake on the trailer???

-

I'm removing my cassette deck and putting in a mp3 jack on my 87vr. I found a few threads about this but am still a little confused. I understand jumping pins 1 and 7 to bypass the deck. Which ones do I wire in the switch and jack to? Does anyone make something I can just plug into the old cassette wire and go? Any help would be greatly appreciated. I'm mechanical but no electrician, so please be as specific as possible.

-

The nice man in the big brown truck just showed up again at my house. This time he had a small box with a Hi-Lo beam HID setup for my scoot. It has all of the wire harnesses and is supposed to be plug and play. The system has a relay and a fuse already in their wire harness. It is a 35 watt system so I will have a little more power for something else. I will wait to install it till I can get out on a dark road to get a before and after pic of what the light looks like shining down the road. I'm sure gettin lots O new toys on the scoot this winter.

-

Inspired by THIS POST, I installed the Electrical Connection Turn Signal Conversion Kit (EC-01315, bought HERE) on my 2006 Royal Star Tour Deluxe. There was one crucial step that was puzzling, and I made a few false steps. What follows is what I would do if I had to do it over again. I am posting this in the spirit of sharing lessons learned. *Insert more disclaimer stuff* I got a rolling seat for Christmas as well as two magnetic parts dishes. These were great for not losing parts. Spend a minute and organize where you'll put stuff. 1. Put the bike up on a stand. I love the Carbon_One "RSV / RSTD Lift Frame Adapter" as sold HERE, especially with the legs. Puts the bike solidly at a good working height. Note that you will want the bike up in the air, since you will be working inside the rear fender. 2. Remove the blinker lens cover and silicone-glue in the LEDs as per the instructions. Note that although the LEDs are white, they will shine red. 3. We'll do the hard part one side at a time, and for fun's sake I'll pick the left side. The turn stalk is in two parts held together with a bolt. Before you loosen the stalk, remove this bolt to let the halves pull apart. Doing it while the stalk is on the bike is simply more convenient because it is solidly anchored. 4. Go inside the rear fender and unclip the left turn signal wire. There are three thin metal clips that hold the wire inside the fender. Bending them out and freeing the wire will give you slack. Note that dirt may fall out of your fender and into your eyes. Be smarter than me and use eye protection when you look up into a crud caked fender. 5. Remove the two bolts and heavy clip that hold on the left turn stalk. Note that the turn stalk may flop and ding your fender paint. Just be aware. You can push the slack wire out the exposed fender hole. 6. With the turn signals dangling, use a screw driver to pry apart the slot in the outer stalk, allowing you to separate the stalk into two parts. 7. Now, examine what you have and what you have to do. You will need to somehow thread the LED leads past the turn bulb seat and through the stalks. This is the step that stymied me for a while. Once I figured that out, the right side took 15 minutes. There are undoubtedly many solutions, but this is what I did: 8. I removed the bulb, then removed the two screws and thin metal strip that holds the bulb seat. 9. I used a metal skewer to slide from the stalk end into the blinker housing, between the rubber bulb seat and the metal outer housing. The bulb seat seems to be affixed, perhaps with glue but more likely a tight fit and age. I thought I was going to use the skewer to make a hole for the wires to go. Instead, I noticed the bulb seat was moving into the blinker housing. The skewer seemed to have broken whatever bond there was, holding the bulb seat in. Using a pair of pliers, I gave a gentle pull and the bulb seat came free. There were two wires still attached to the bulb seat, so I had to be gentle. 10. With that crucial step completed, I used the supplied vinyl tubing to thread the LED leads through the housing, then through the other part of the stalk. At this point, untwist the LED leads so that they will lay flat between the rubber bulb seat and metal housing. 11. Reinstall the rubber turn signal bulb seat. I ended up having about 2.5" of LED lead sticking out, situated on the bottom of the housing. I don't think it matters much, but make sure you keep plenty of wire showing as you shove the bulb seat back into place. I happened to have a 6mm socket handy, and it fit perfectly into the bulb seat. I used that to press the seat in evenly. I did not get it all the way back in how it was. Perhaps 1mm extra is sticking out and it threatens to contact the bulb. But since the bulb only blinks intermittently, I am unconcerned. If you are concerned, maybe you could take more care than me. *TIP: Use WD-40 to lubricate the outside of the turn signal seat. That will allow the seat to slide in easily and not damage the LED leads. Electrical Connection says that this is the location with the most frequent problems--a pinched wire. They will cut a groove into the seat with a Dremel, but that seems risky to me. See my post below describing the problems I had. 12. I went ahead and reinstalled the amber turn bulb. This involved installing the metal strip and two screws that holds the housing in place. This is when I noticed how slack my attempt to reinstall the bulb seat was. Oh well, the bulb fit in and works. The steps 8-12 above took me 2+ hours to figure out, even with some hints from VentureRider.org. Lots of anguish over this. But the result seems pretty good, and took 15 minutes on the other side. I think making sure the wires are flat is important. 13. I used the skewer inside the supplied vinyl tubing to push the tubing through the rubber gasket holding the wires through the fender. Then I fed the wire through the tubing and into the inside of the fender. Almost home! I pulled out the tubing when it was all fed through. 14. My wife helped me for two minutes as I re-installed the turn stalks. She held it in place while I pulled the slack out of the wire, pushed the wire back over the retaining clips (including the new LED leads), and installed the heavy clip + two bolts. Wiping dirt from my eyes, I crawled out and put the turn stalk halves together using the nut and bolt. It looks like there is some red locktite on this bolt, but I don't have any. I'm not sure anyways. I'll make sure to check the bolt. 15. Remove the license plate to expose wiring. I was greatly surprised to see that there was a bundle of wiring back there. This is, I think, what the instructions in the Shop Tip mean about the "mustache. " I have a mustache, but I don't think my bike does. Anyways, this is where I did all the connections. I snipped the zip-tie holding the bundle together. Maybe there is a better way to unbundle than snipping. Will someone let me know? Separating the bundle and looking at the wires, you can make sense of how the wires come out of holes on the fender from either side. You can see which wires feed the left turn signal and which feed the right turn signal. 16. [Optional] remove the brake light lens cover. That way you can see the blue and yellow wires that operate the turn signal. I found it handy to have that visual color cue as I did the wiring. 17. I used the same piece of vinyl tubing plus the skewer to poke through the fender again and into the license plate area. I pulled the slack out of the LED leads, removed the tubing, and got more dirt in my eyes bending the retaining clips back inside the fender. At this point, the left side wiring is done. If you are nervous (I was), turn on your lights to make sure your turn signal still works. 18. Do the right side, learning from the left side. If you want, you can do the connection stuff for the left side first so that you can see how the turn signal gasket goes back using the right side as a guide. The gaskets for the turn signal lenses constantly fell out for me, and I eventually just learned how they went back. I did the right side wire-routing first, before doing the connections behind the license plate. 19. With the right side done too, you can start the wire connections. I found this part scary, because I am not an electrician. But connecting the supplied heavy red-green-blue wires turned out to be easy. 20. I snapped the T-Tap onto the heavy Blue and Yellow wires from the brake light. 21. I wound together the two green wires from the supplied three-wire strands, and then crimped on a one connector. That's what they mean in the instructions that "The 2 greens can be connected together." (Hey, go down and read Step 30 and make a decision about how much wire you need.) 22. I wound together the two blue wires from the supplied three-wire strands, and then crimped on a one connector. That's what they mean in the instructions that "The 2 blues can be connected together." 23. Now you have a blue and a green connector ready to plug into the T-Taps on the blue and green break wires. What would you do? I assumed the blue wire connector went to the blue wire T-Tap. That turns out to be wrong. The supplied blue wire connects to the T-Tap on the yellow brake wire, and the supplied green wire goes to the T-Tap on the blue brake wire. If you do it backwards (I did), all that happens is that the LEDs come on all the time with brake-strength. If you do it right, they LEDs come on with running-strength, and power up when you pull the brakes. 24. At this point, I completed the instructions for the left side. That means connecting the supplied red wire to the black/white LED lead. Oh, it also means cutting the LED leads to length, and stripping the wire. You also use a T-Tap to connect the black LED lead to the colored turn signal wire. The turn signals have a color wire and a black wire; tap the colored one coming from the correct side of the bike. Left LED lead goes to left colored wire, etc. At this point, I experienced my first real dissatisfaction. The skinny LED lead simply does not want to stay in the crimped connector. I used vise grips to crimp the snot out of it, but I know it will pull out. I plan to get a soldering iron and make sure the connection is solid. Luckily, all I have to do to access these flimsy connections is remove the license plate. 25. Plug in the leads onto the LEDs glued to the left turn signal lens, following the directions. 26. I turned on the bike and, GLORY!, I had a dazzlingly bright red LED running light! Try the turn signals. It works! Pull the brake handle. The LEDs get even brighter (if you connected the blue/green wires correctly; supplied blue=>yellow brake, supplied green=>blue brake). 27. Turned off the bike, stuff the leads into the housing, make sure the gasket is correct, and screw the lens cover back on. The entire left side is done. 28. Do the right side, trying not to grumble too much about the crimped connector. Plug in the leads, test it, and reassemble the lens. Note: while the leads on the right side clearly had a black and white stripe, down at the plug end I really couldn't tell which wire was which. When I tested the light, the LEDs did not come on. Simply switching the plugs made it work. 29. With the wiring all complete now, test it to make sure the functions are working. At this point, I realized the LEDs were burning at full brake-strength all the time. I switched wires. You can never do too much testing. 30. [if you did step 16] Put the brake cover back on. 31. Now put all the wires back into the nook behind the license plate. Reinstall the plate. I realize now that I should have cut the red/green/blue wire bundles, because there is a huge amount of wire trying to be jammed into the small nook. You have maybe 6" of wire when you need only a couple inches. The pre-stripped wire ends were simply too appealing, and I should have cut them. Now I have no spare connectors so I am kinda stuck. I'm going to a electronics/electrical parts store to see if maybe I can find some more connectors. I'll cut the wires when I solder the LED leads. 32. There is no step 32, because after step 31, you are done. Well, at this point you can take pictures and feel a bit of pride. You can also let me know if I screwed something up in these instructions. Sharing lessons-learned is one of the best parts of this site.

- 9 replies

-

- bulb

- led turn signal

-

(and 3 more)

Tagged with:

-

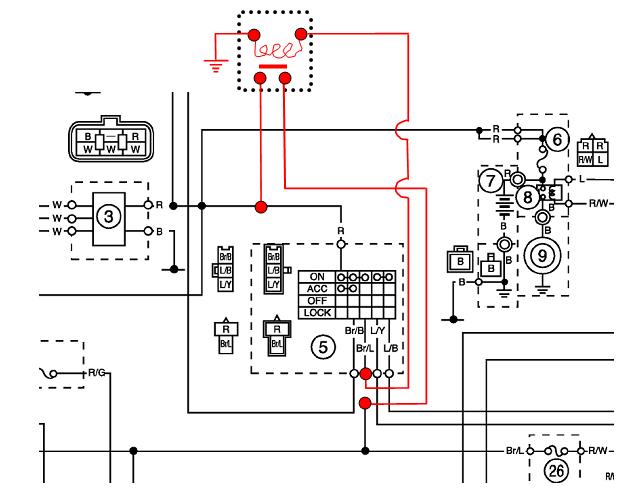

There's been several times members here have by passed their ignition switch due to either switch failures or as a preventive to ward off failures. Today I decided to also do that to my bike and at the same time do a write up on it per a recent posting on this topic. For those who wonder why this is needed or desired the ignition switch has the majority of the power going thru one wire to feed lights and ignition requirements. Needless to say the switches contacts take a beating over time caused by overheating & normal wear & tear. The accessory part of the switch seems to never have this type of failure so this does lend credence to overloading on the one line being feed. By adding in a common 30 amp auto relay to that part of the circuit we can take the majority of the power off the switch before it gets there and route it directly to the line the switch powers, thus saving the switch. You'll need a couple of short 14 gauge wires, push on terminals, shrink wrap, and a 30 amp auto relay to do the job plus a soldering gun and wire stripper. To start you need to remove the drivers seat and gas tank. The gas tank is held on with a single bolt on the end by the seat plus two allen head bolts on the sides up front. Remove the cover by the ignition/gas cap. Disconnect the overflow vent hose and the fuel sender wires. The tank can be lifted off and set down out of the way now. Disconnect the (-) negative cable from the battery as you'll have one wire live otherwise. On top of the engine locate the wire harness coming from the ignition switch. There will be two red plug connectors going through a holder. Pull those out. The one you'll be working on will be the 2 wire one with a pink plug on one end disconnect that plug. Picture 1 shows it well. The next step is to splice a wire to the red wire with 14 gauge leaving it long enough to work with. Refer to picture 2 Cut the brown /blue wire leaving enough at the plug side to work with. Add a short length to both ends of the cut wire. Using a butt connector, soldered, and covered with shrink tubing will give a solid connection as well as protection . Add a female spade terminal to both of those ends. Do the same for the red wire spliced earlier too. Cover with shrink tubing after soldering them. Make a ground wire with a eyelet end on one end and a female terminal on the other. See picture 3. I used the closest bolt holding the radiator fill cap in place to ground the eyelet. The opposite end will attach to the relay. Connect the wires to the relay follows: spliced Red wire fastens to #30 terminal of the relay the brown /blue wire from the switch attaches to #86 terminal on the relay the brown /blue wire going to the harness connects to#87 terminal on the relay the gounding wire attaches to the #85 terminal on the relay. Wrap the wires up with tape and tuck them back into the harness holder. Pics 4 & 5 show the completed job with the relay as tucked in on top of the engine. Note: While this mod will prolong the life of the switch a long time there's always the posibilty that the switch can still fail through normal wear. If it does you can simply connect together the red wire and the brown/blue wire on the harness side to get you home. Some folks take this a step further and add a toggle switch between the two wires. I don't think it's neccassary on newer bikes but if you're experincing any ignition troubles now then I would certainly see the advatage of adding a toggle switch where you can get to it without having to remove the tank.

-

was on my first night ride. going down the highway thought it was cutting out but wasant sure still had plenty of power. then was town driving stopped at the busiest intersection would not rev up then all power went dead. pushed it to the side nothing. pushed into a church parking lot pulled cover off. reached down to left side of battery. lights came back on. and would start. rode one block same thing. so every time it would start cutting out would reach under left handle bar wiggle wire and it would straighten out made it home doing this. any ideas. not the fuse box or battery cables. wire to computer above the area. :think: why why

-

Always cracks me up. Well, as long as it's not costing me a bunch of money to make right. I just bought a dang near new HF Tag-A-Long right. I got it cheap enough. I knew when I looked at it I had a few things to deal with. The coupler was crushed into the tongue as the PO had not used washers to shim the couple and it has pulled in so tight the latch for the ball would not move without being pried down with a pry bar. I had to remove the hitch and the latch assembly to get it over the ball when I hooked up. Got that corrected today. One handed hookup now. When saw the trailer the first time I knew something was not right with the wiring. I'm no whiz kid when it comes to electrical but I was pretty sure there were too many wires coming into, through the frame and into the tailight housings. I was right. More than needed. There was an extra wire with a female crimp on connector that ran forward with the 4 wire trailer plug. My best guess at first glance was maybe an extra ground wire. I chased it today and it ran through the frame and was spliced and split into both taillight housings. Holes had been drilled and the wires ran inside. I pulled the lens off both sides and it all made sense. And extra 1156 bulb had been installed in both housings. Not to mention one of the 1156 bulbs had come apart and was laying in the bottom. I hooked up a fused jumper wire and powered the extra wire from the front. Blew da fuse. Pulled the wire and it was cut into where the wire ran thought the holes in the frame with zero protection. Nice. So I can kind of understand the thinking here...... maybe the PO just wanted a couple running lights at the rear. Went the hard way about it in my mind. Now when he hits his lights he had (2) 1157's, (2) 1156's and (4) 194 wedge bulbs lit up. Then add the brake lights and the voltmeter has to be taking a nose dive into the red. I'm seeing why the PO may have been happy to trade off the damn near new Tag-A-Long and be done with it. Can't hook it up, throwing sparks and some lights had quit working and the battery was probably taking a beating. I got to admit, I'm enjoying the old "His loss, my gain" moment. Oh, and I checked the zerks and one was not only missing but a plug had been installed in the hole. Nice touch. Mike

-

I started that thread a while back on "The things you find" and it just kept going the farther I got into the New/Used HF Tag-Along I bought a while back. The PO had to be one creative bugger to get the kit as far as he did. But then he did get rid of it before going anywhere and I got a pretty good idea of why he did now. The wiring..... geesh! I think he used a drill and razor wire to fish the harness through the frame. I couldn't go 2 feet of wire without finding a chewed up or broken wire patched with ScotchLocks with the bare ends hanging out inside the frame. In the end I had to replace the entire trailer harness and considering the mods to the taillight housings he did, I broke down and bought the HF LED kit and installed it. At least the LEO's won't be shaking my tree for a license plate light being out. That sucker lights up with the LED's. But after installing the new harness, shielded with harness wrap, and soldering and shrink wrapping every connection from the 5/4 converter all the way to the tail lights I'm sure it will serve me well for quite a while. Still need to tuck in some rubber grommets where the harness goes through the frame but that's a quick fix. Got the 5/4 wire converter tucked in by the frame under the seat. Piece of cake hooking that up. I hooked the side markers and rear tails to the marker lights on my switch panel. That way I can kick the lights on all the way around without the key in the bike. Had one moment there where I was ready to panic because the four ways weren't working until I remembered I hadn't hooked up the brake light wire yet. Whew! I don't like loose wires on my bike so I added a plug holder on the rear light bar for easy access. Nice clean connection. I got the rubber hose installed on the rear spring bolts. New zerks are in. Coupler has been bent back to the original shape and washers installed. One handed hookup now. Siliconed in the frame plugs, or at least three of them. Missing one so that search is on. Cleaned off the Vaseline that HF uses off the wheel bearings and packed them with High Temp and set the bearings. Got my Nebraska trailer plate mounted. Note the size of that thing. I never noticed the bike plates here before but that sucker is gonna cause some serious drag. Suppose I should mount another plate on the other side so it don't lean. Going to make some mini mudflaps for the trailer tires. Need somewhere to mount some of those lil chrome nekked ladies. Well, looking at that pic maybe I won't need mudflaps with that big ol plate hanging there. My friend (The Piper) that pinstriped my helmet last year stopped by and was eyeballing the trailer. I know what he's thinking......He was grinning. So I miss anything? I'm going to have to go out and drag it around now and check out. Looks like it's gonna rain. Guess I'll find out how water proof it is. Mike

-

Going to try this again. Anybody have an old , bad, removed, ignition coil from a 2nd gen laying around ?? If you replaced a coil, could you pull the plug wire out of the " old " ignition coil, and take a photo, or let me know, if the plug wire can be " Re-Installed " after you pull out the old one ?? ie: is there a pointed SCREW inside the hole the same as on the 1st Gen Ignition coils ??? I'm trying to figure out if I can replace the plug wire on these coils, but do not want to destroy a good one in the process. Any help here, appreciated, thanks.

-

Ok, we all know that on 1st Gen coils, you can eaisly remove the plug wire from the coil, and the spark plug cap. On the 2nd gen coils. the plug wire appears to " NOT " be removable, ( or replaceable ) from the coil end, of the plug wire. SO-- I was looking at my right front Ignition Coil on my 08, yesterday, and where the plug wire go's into the Coil, it appears as if there is a " Sealant " applied around the wire where it mounts into the coil. What I am getting at here, is I would like to replace the Plug Wires, with some type of " Shielded Spark Plug Wires " . Anyway, so I am wondering if maby I Could remove , and replace the wires from these coils. Does anybody, have a Used ( ie: removed and replaced coil ) laying around in their garage. If So, any chance I could get you to take the old coil, and pull " out " the plug wire, and take some close Ups, of what the hole looks like, and what is inside the hole after you pull out ( ie: remove ) the old plug wire. I hope this all makes some sence, any way thanks to anybody who might be able to accomplish this, I'm working on " Reduceing " Ignition Noise on the AM radio I have installed on my RSTD. And installing Shielded Plug wires might be of some help. ---------------------------------- Next Qustion : ??? Just curious, has anybody, Installed the 1st Gen Ignition Coils, on a 2nd Gen Bike ???? this would obviously solve the plug wire problem, if the coils will work on the 2nd gen bike . I make this point, because it very easy to replace wires on the 1st gen coils, and lots of them avialable, I allready have two of them, and would only have to find 2 more to do the job, if this is possible. ?? --------------------

-

I just finished replacing the stator on my 87 VR. Thank God for the volt meter on the dash, it allowed me to notice that I wasn't getting charging voltage before it was too late, and I rode the bike home on battery power. What a pain this job is! The stator part is typical - remove the cover, replace the stator, deal with the little rubber plugs where the wires go through. But, as has been noted, the screws holding the stator inside the cover are SUPER TIGHT with Loctite. The gasket was like a piece of granite bonded to the cover - very difficult to remove. And finally, there's the little cavity behind it with all the oil leak opportunities. Ya know, behind the cosmetic flange on the bearing cover behind the stator cover? Mine was an oily mess. I found on this fine website that oil can leak from either of the wire plugs in the stator cover, the gear selector switch, the shift shaft, the clutch slave cylinder installation, or the gaskets themselves. And all of these are packed into a tiny area too small to see, much less work in, which was difficult to clean out because my engine was sitting open with two covers removed and I didn't want crap to get in there. There's also 4 wire bundles that go through there, plus a convoluted shifter design with TWO linkage rods, 4 heim joints and a jackshaft! No wonder the shifter on this bike is not the smoothest I've ever used. I was pretty sure my leak was not coming from the clutch cylinder. That left the gaskets, gear switch o-ring, wire bundles and shift shaft as possibilities. I was already replacing the gaskets and redoing the wire bundles. The gear switch o-ring was low-hanging fruit, so I did it. As others reported, I found one of three retaining screws missing and another loose. Re-installed with Loctite. I did not do the shift shaft seal because, frankly, it looks like a total pain to do and I didn't wanna! I am hopeful that the leak was not there. Well, the good news is that it runs great, charges great, but dunno yet about leaks. I installed the hi-output Rick's stator. They don't list it, but I learned about it here; it is in their Hot Shot series. They don't really give any specs on what to expect in terms of increased performance. I can tell you that by 2000 rpm it's generating 14.75 volts at the battery, even with the driving lights on (stock regulator). Even by 1500 rpm with the driving lights and heated grips on it's getting up over 13V, where charging is starting to happen as opposed to battery drain. I never drive it below 2000 rpm except idling at signals. I don't have any "before" data to compare it to, but my impression is that I am getting more charge at lower rpms. I know that before, if I had my driving lights and heated grips on and was running around town I would gradually deplete the battery. Thanks to all who have contributed to stator and oil leak info on this site. That info makes all the difference when doing the job. Happy New Year, Jeremy

-

Hope someone can help with this issue. Two weeks ago my speedometer and all other digital gages quit too. Took apart and checked for power. I noticed that if I disconnected the r/g continuous 12 volt power source wire and then turned on ignition key, all gages would work. And if I reconnected the r/g wire all was fine. But as soon as I turn off key and turn on again with r/g wire connected my gages will not work. Disconnect and turn on key all is fine. So I thought I would connect a toggle switch on the 12v r/g wire and test out on the road. Ok now hear is where the big problem is. I decided to go to gas station to make sure gas gage would work. Started down the road and ran thru first and second gears no problem. Started ramping up in third and when I got to approx. 45 mph the motor just fell on its face. It acted like u just cut off the power. Forth and fifth forget it it will not hardly run at all. Anything over 45 from third gear on will not run. The bike will run fine up to as fast as 65mph in second and not flinch. Shift to third and it will lay down til u get back down to about 40mph and u can cruise there and slower all day long. BTY. Before I started messing with the Speedometer the bike ran like a scalded dog,

-

It does happen, well it seems to anyways,,, and it's not the first time she went and did this,,,can't blame me really, I mean I was trying everything and I really wasn't looking forward to do any straining or hard work. Ya I know, I should have been more cautious out there in the farmers' field doing a slow turn, but crap happens and it happened again yesterday. And then the smoke started coming out of the wires,,, oh no, that means I might have to walk home,,, not a good thing either,,, but hey, all is well that ends well,,, right???? Now the story. Went for a nice ride yesterday to Wainfleet ONT to enjoy the times of yesteryear. Lots to see and do. Followed our fearless leader over hill and vale, around curves and corners, dodged pot holes and road kill and finally ended up at our destination, but alas there was limited parking for kickstand bikes, but if we did a u-turn in a field we could park on some gravel... good thought,,,,, until,,,,,,,,,,,,, well that's where it happened, doing a slow turn, unable to give much throttle, through pasture, the front wheel decided to head further left than it was designed and Scamper did a slow roll over. All seemed to be ok, except for Marca who decided not to stay put,(can't say as I blame her) and put her foot out and promptly fell over and hurt her shoulder, (it's ok now). She says she knows better, we have been down before and she stayed put with absolutely no damage at all,,, interesting to see that,,,, bike on it's side and Marca sitting there yet like it's going somewhere, but not this time. Got help from Wayne and Steve to set Scamper back up and view any damage. Not much really, a broken air wing, a mirror facing the wrong way, hiway peg not in the right spot and just a little smoke coming out of a wire,,, life was good, could have been serious. Turns out, the smoke was coming out of the running light wire, right where it attached to the fuse block,,,was a loose connection, but rode home with the 4 ways on until I could get it fixed,,,, ready to ride again,,,, 10 am Monday. Freebird will want to keep me as a member,,, I pay well.

-

Just replaced the battery in my 86 VR, I noticed the battery that came out of the bike had a wire coming out of the top of the battery, what does this wire do? The new battery has no wire or a hole for the old wire to go into, do I need to drill a hole?Thanks.

-

Would anyone happen to know the wire color and were it might be for the Electronic Speedo for the Second Gen. ? Adding a gear indicator soon. just for another project. I know it doesn't have a relay bit thats OK ! Thanks, Jeff

- 7 replies

-

- color

- electronic

-

(and 3 more)

Tagged with:

-

I have nothing displaying on my cmu. Not even when turning ignition on, when it should go thru each item. It was working a month or two ago, but now nothing. Is there a common power wire for the display? The display lights up with the dash lights, but displays nothing else. While putting the bike back together, I did put a small gauge black ground wire on the positive battery terminal. (lesson learned: put down the tools when talking to your 8 year old daughter) The wire melted down, and i followed it to the main negative cable. It was in a factory crimp with a few other grounds. After that, I have had to run new wires on the taillights and brake lights on the positive side, not the ground. No fuses blew, and i don't see any other fried wires. Maybe some damaged wires that I can't see in the harness some where? Time for a harness? Coincidence? sun spots? UFO's?? :confused24:

-

I started up the bike and started pulling off the spark plug wires one at a time. The ideal change on all them but right rear. I pull the plug and put a new one in and put the plug wire back on and pulled back of the ideal didnt change like the others. i pulled the wire back off and i could hear it fireing and as i was pulling the wire out I could see the arc and it shock me. any ideas. my #843-452-8615 my name is Brantley

.thumb.jpg.176b2ebbe9863175975d94710375c414.jpg)