Search the Community

Showing results for tags 'torque'.

-

has anyone tried these?http://www.baronscustom.com/catalog/display/305/index.html

-

Sorry I could not located the specs here. Can anyone tell me the torque specs for installation of the rear wheel. Thank you.

- 1 reply

-

- installation

- rear

-

(and 3 more)

Tagged with:

-

Anybody here have any experience with rebuilding them? I tore up the spider gears in my 78 this spring. I had bought a new ring and pinion to change the ratio from the 3.25:1 that was in it to go to 3.89:1 so it would be more ideal with the transmission gearing, peak horsepower, and tire size I would be running a while back. Now is a good time to get them in while I was replacing the diff case seeing as how the original one had holes punched through it. But now that I have everything together, I need to set the rotational force on my pinion and carrier bearings. But I don't have a torqometer, and a spanner wrench would also come in handy. Would anybody happen to have either of these and be willing to lend them or help out who lives in the Thorp/Eau Claire/ Chippewa Falls/ Abbotsford , WI. area? Anybody have any tips or hints that I should be aware of? Anybody have the proper torque specs? I've found several places on the net with them, but they vary a bit from one to the other. One says to set the preload on the pinion to 22-32 inch lbs., which definitely feels way to tight. I just don't want to go through all the money and trouble just to have the thing melt down or explode on me. Thanks for any assistance, Bill

-

Looks like I ended up with an extra torque wrench. It is in a red case. PM me with your address if it is yours and I'll get it mailed.

-

I saw links to aftermarket slip on and complete exhaust systems. There were sound clip links to listen to. Very interesting, but how about real world performace increases? Has anyone posted results besides sound of the different exhaust systems? HP/ Torque, driveability, heat issues, MPG impact, ease of install, etc.? Thanks. Steve

-

I posted last week about the creaking noise coming from the rear. My option was to get it done on warranty or do it myself. Not sure of myself I printed the info from the tech section and tackled it myself. Not a bad job and it will be easier next time. It took me a couple of hours but it is 60 miles to the dealer so that would mean two trips and four hours on the road. I will finish up tomorrow night in about 15 minutes. My torque wrench only goes to 75 lbs and the axle calls for 140 lbs. Any ideas short of buying another wrench. Thanks to those who take pictures and help with the tech forum! I love this site!

-

I've recently purchased a 07 RSTD with just a bit over 40,000 miles. I've read about some having to replace the CLUTCH BASKET and it being under warranty. I've recently changed the oil just to know it had been changed and what was in it. I replaced the oil with Full Synthetic Mobil 10-40 High Mileage formula (non energy conserving) I had noticed the slipping feeling before the oil change but do not know what oil was in it) The reason I ask is I have experienced what feels like a clutch slipping under hard acceleration. I am not sure if this is a idiosyncrasy of this bike or if it is actually slipping and/or will need replacing in the future. My wife's HD Fatboy has the same feeling too when I run it hard and it only has 8,000. miles on it. I had always attributed the feeling to its belt drive stretching. At 8000 miles I doubt it is slipping, and it runs out really well but he HP and Torque #'s are no where near the TD's or Valkyrie's. (all work on it has been done by a dealer.) Since the TD is a shaft drive I would expect it to feel like my Valkyrie which once engaged in a gear it stays no slipping under hard acceleration at all. Just lots of torque. Both the TD and the Valkyrie have hydraulic clutches, the TD is a much lighter feel than the Valkyrie so is it safe to assume the clutch springs on the Valk are heaver to deal with the extra torque? 2ND ??? What are the symptoms of the CLUTCH BASKET needing to be replaced and HOW CAN I TELL IF IT HAS BEEN DONE OR WHCH BASKET IS IN MY BIKE? Thanks for all the help, Tom

-

Shopping for a digital torque and saw this: http://www.sears.com/shc/s/p_10153_12605_00944596000P?blockNo=7&blockType=G7&prdNo=7&i_cntr=1296146568248 Anyone have one? Anyone suggest something a little better? What's your favorite?

-

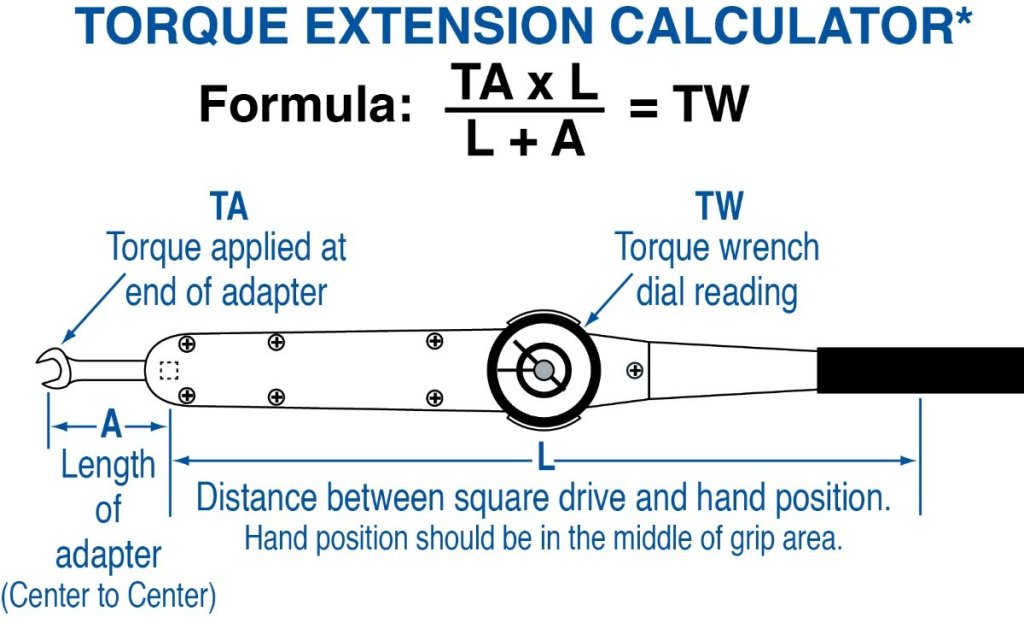

Submitted by Saddlebum. Proper use of steering head wrench with torque wrench By the way everyone for some of you who may not be aware of this, There is a small issue you need to keep in mind when using this tool with a torque wrench. If you mount the tool on on a torque wrench at a 90 degree angle to the torque wrench . You may set the torque wrench to the exact torque spec. If you mount it at a 45 DEG. angle or straiaght in line. You have to do a small calculation to compansate for the additional length. In otherwords you set your torque wrench at a lower setting to compensate for the added length. Here are two links that will do the calculation for you as well as explain it. The second link actually gives you a pic of the torgue wrench setup. you simply fill in the boxes and it will tell you what set your torque wrench at in order to reach the desired torque. https://belknaptools.com/extensions-calculator/

-

Anyone using Harborfreight torque wrenches? Any opinions one way or the other? Thanks!

- 9 replies

-

- harborfreight

- opinions

-

(and 2 more)

Tagged with:

-

Replacing front tire and need help with torque for axle bolt and pinch bolt.are there any web sites with torque spec. For the venture. Thanks again for all your help

-

I didn't have anything to do this afternoon so I thought I would tackle the HD Clutch Spring Kit.... I was almost wrapped up, snapping pictures the whole way when I snapped one of the 6 bolts off that holds the spring on......... OK so I was using a torque wrench that starts at 10lbs.. So I backed it off to about where I thought 5lbs would be (Note: Don't do this)..... I'm a big O dummy!! As I am tightening the bolts I am thinking these are not getting tight, so I started backing them out when one snapped off . These bolts must be crazy soft, because I didn't feel like I was over torquing them . Providing I can get this one out :/, I am replacing all six bolts and buying a torque wrench that measures inch lbs. Couple of questions- Should I use loctite ? As I said before it doesn't seem like they were very tight at all... Do you think I weakened the new spring?

-

I'm confused in the head over horsepower versus torque!! I have wondered about this for years and never got a satisfactory answer. I have read and believe I understand the definition of horsepower and what it means. I also know what torque is, how it's calculated, and what it does. My problem is when I mix these two pieces of info together in my puny little brain I get the idea that horsepower and torque should follow each other. That is..more horsepower should produce more torque. Conversely, if you need more torque, make more horsepower. Just seems reasonable to me. However, if you look at dyno results you see I am all wrong here. Typically HP increases to a certain point then starts to drop off, while torque continues to increase. This makes no sense to me at all. Can someone please explain the real relationship between the two (if any), and where my thinking goes south on me? Lucy!!!!Gu got som' 'splanin' to do!

-

Anybody know ? Cb

-

Just changed my oil/filter, put the drain plug back in and, using my "trusty-dusty" Harbor Freight Torque Wrench, torqued the bolt to specification. The result?? I now have a stripped drain plug bolt/oil pan. After I fork out a pretty penny to fix this, I will NOT be using another Harbor Freight tool on my baby. ANy one else ever have an issue with an H.F. Torque Wrench?

-

Beam-type torque wrenches are very imprecise, but much better than nothing. Clicker wrenches should be periodically calibrated, but virtually none of us go to the expense and effort to have that done. But you CAN check them yourself. Checking the accuracy of a torque wrench is not too difficult IF you have at least two wrenches with overlapping ranges. Here's how: You need a high grade bolt and nut - I prefer grade 8 (six radial lines on the head) where a 7/16-14 bolt would allow you to test up to around 70 ft lbs. Make sure the threads on the bolt go all the way to the head, and put at least one large washer on the bolt. Now clamp the nut in a vise with the top side flush with surface of the vice, then screw the bolt all the way in. Set your first torque wrench to a low setting in the range that is covered by your second wrench. For example, if both wrenches go from 10-100 ft*lbs, I would start at 15 ft*lbs. Carefully tighten the bolt in the vise until the wrench clicks. Now switch to the second wrench, set to the same torque, and see if it clicks BEFORE the bolt turns at all. If so, that is good, but you are only 1/2 done! What you have just shown is that the first wrench did not tighten the bolt any LESS than the same setting on the second wrench, but it MAY have tightened it more. So to complete the check, you need to loosen the bolt, then repeat the above steps starting with wrench #2. If this test also shows the second wrench clicks before the bolt turns any more, then you can be confident that both wrenches are setting the same torque, so they are almost certainly both correct. Now increase the setting on both wrenches up to something in the middle of the range and re-do the whole test. The only thing you need to be careful about is to make sure the max torque setting you test is within what the bolt grade and size can handle. If the two wrenches you are testing do not both click at the same setting, no matter which one you start with, then at least one of them is bad. To find out which one, you will have to find a third wrench to test. When you have two wrenches that both click the same when you do the entire test above, then you can use either one of those as a baseline to compare other wrenches. Just an FYI to anyone who brashly wants to claim all Harbor Freight torque wrenches are junk - I have a total of 5 torque wrenches here - two from HF (a 1/4" drive clicker and a 3/8" drive clicker), an old beam type wrench in in*lbs, and two very high quality 1/2" drive clickers that were calibrated by a USAF test lab. ALL of those wrenches test the same in every point where the ranges overlap, so the HF wrenches are dead accurate within a reasonable tolerance. The only complaint I have at all against one of the HF wrenches (the 1/4" drive) is that the gradations on the handle are a bit more difficult to use when setting the torque value - I had to compare it to the other wrenches to be sure I was reading it correctly. So if anyone in the North Texas area wants to check their torque wrenches, we can compare them to mine. Goose BTW - How you store your clicker-type torque wrench is important. If you do not have (or haven't bothered to read) the instructions that came with your wrench, you might be in the habit of just chucking the wrench back in your tool box after that last "click" on the last bolt of the job. But it is important to turn the torque setting all the way down to remove the tension from the internal spring before putting it away. Leaving the spring under tension is the biggest reason why these types of torque wrenches change calibration.

-

Had it dyno'd and it is running way to lean up to 4k rpm. Above 4k starts running too rich. Having it rejetted and dyno tuned. Best on torque and hp was about 74 each. It ran like the harley I used to own. I expected more power and torque. Mech is rejetting and will let you know what the power difference is. My brother owns an '07 Venture so I will have something to compare with. Mech says I will walk off and leave him. Hope to gain significant power. Will not change pipes, loud pipes messes with my music listening. Has anyone put the performance jets and how well did the change work on the Venture.

-

I have completed putting in my new steering bearings. BUT no where in the service manual does it give the torque spec. for the fork brace all our 1st gens have. Torque spec. is typically the result of female metal strength, size and thread of bolt. LOOKING at the bolt. I think 14 ft/lbs would be about right. Anyone know the spec for sure? Oh, and I do have the super brace. But I know that does not alter the OEM correct torque setting.

-

I received my clutch today and decided to go ahead and install it. I got it all took out and started putting it back together. I got it all back together and was putting the bolts back in the clutch plate. I was trying to torque them down with my old torque wrench and one of the bolts snapped. I finally managed to get it out after about an hour. My question is does the bolt have to be a certain kind or will any kind due? My torque wrench is the old kind that has the bar that comes up with a red end on it that moves down the gauge that tells you what your ft lbs. Do I need to invest in a newer one? Thanks hairman

-

How many use torque wrenches for routine maintenance and who tightens until it is "about right"? I realize that proper torque is absolutely critical for some applications. Do you use more than one wrench (i.e. low range 1/4 or 3/8 plus high range- usually 1/2")? What type of torque wrench do you use (i.e. "clicker")? I have heard it mentioned that the torque specification (by Yamaha) for the axles are too high. For instance on the Roadstar, I believe that 110 ft.lb is recommended for the rear wheel while the general concensus is that 80 or so is sufficient. Any opinions for the RSV? In the past, I have generally borrowed a torque wrench to use only for things I consider to be critical but I am thinking about buying a couple of new ones to cover the necessary ranges. (I have used the "about right" method for most stuff) Thought I would solicit some opinions. I am not into major stuff - I would leave an engine teardown to someone who knows more than I do - but I prefer to do everything I can. Thanks Ross

-

Does anyone know how tight (Ft pounds) to get the 6 bolts that hold the diaphram pressure plate on a 87 VR??? I need to put it back together and just found out the correct torque is not listed in the operators manuel. Thanks!!!!

-

I saw a modification on another site which claims that linking the intake ports by joining the same vacuum ports which we use for sincronizing the carbs gives somewhat better low end torque, albeit at a slight sacrifice of idle smoothness....Has anyone here ever done such a thing?????????

.thumb.jpg.9dfefb49018580a1813c8128f131546e.jpg)

.thumb.jpg.0a6cfd8405e77fabc10f21d6e3def9cb.jpg)

.thumb.jpg.4242842914ac7b922022dafee8bac02d.jpg)