Search the Community

Showing results for tags 'sender'.

-

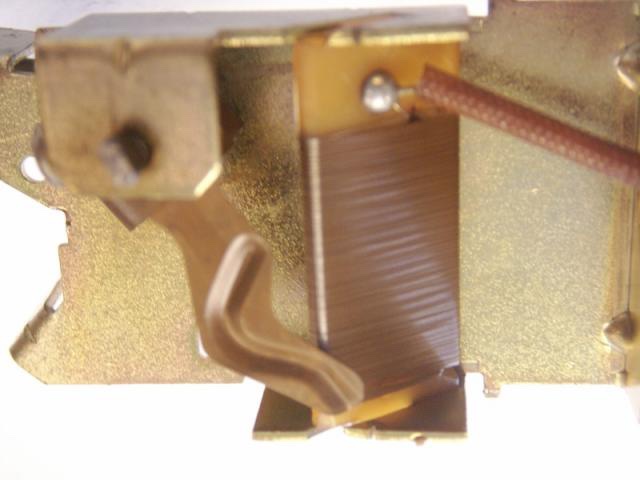

A few posts have been made in the past about the workings of the fuel tank level sender & the petcock. I pulled these parts out of my spare gas tank and took some pictures of them to show how they work for interested members Picture of the sender unit as it came out of the tank. Picture of sender with metal cover removed. The tabs do not have to be bent to remove metal cover. Just spring sides of cover out slightly and cover will slide back. Close up of the wire wound resistor. The metal wiper contact is at middle position in photo. In this view float is all the way down, at the empty position, metal slider contact is now positioned at bottom of wire wound resistor. View of petcock showing adjust lever. View showing the two screens that go into to the tank. The longer pickup tube is for the regular selection. The shorter tube is for the reserve side. Gary

-

Hey, I am having trouble with the fuel gauge. The sender has been replaced. Currently the tank has done 24 miles since full, and the resistance across the sender is 60 Ohms. So all correct there. The wires from the CMU to the sender both have continuity, and, when connected, the hot (Green/White) side is reading just over 5V. Yesterday I removed the CMU and resoldered a few joints, but mainly it looked to be in very good shape. When I got this bike just about every warning light remained on, and we are now down just to the fuel gauge. Could someone check for me what the voltage should be if when the gauge is displaying correctly, because what I am left with appears to be needing a new CMU. If we have any really, really well informed readers, who know which parts of the CMU control the gas gauge, then I could investigate the precise path in the CMU. There is some small, intermittent fault here as I have, on a couple of occasions, seen the gauge work, or at least try to with the gas pump icon out, and one or two bars on the gauge. Thanks.

-

Well, I took the venture out for its second short jaunt, just to get a feel for it. The fork seals are so bad they wont hold air, and the oil SPRAYS out the right seal. It has a definite miss, that comes and goes. It idles erratically, from 900 up to 3000 and back down again, even after synching the carbs. It overheats. I used a thermostat from a Geo Metro (I think) I saw somewhere that it woudl work, maybe its too hot of a thermostat. The oil warning symbol is always on, but it doesn't sound like there is an oil issue. IIRC its a level sender not a pressure sender. My headlight trim ring from ebay is a MK2 instead of a MK1 so the rubber gasket and front glass won't fit. My windshield got messed up while in the garage. Methinks one of my "assistant mechanics" was trying to help out. In spite of it all, it seemed to run straight and handle ok.

-

My fuel gage went from working part time to not working at all. So over the weekend I done a last minute repair before vacation next week.The fuel float assembly is attached to a mechanical wiper arm that brushes across a wire wound resistor in the control unit. As the float bowel moves with a change in fuel tank level the resistance varies from 0 ohms Full to 330 ohms empty. 1. Place bike on center stand,remove seat,unplug the sender connector and clean around the 4 bolts holding fuel float and sender unit in tank. 2. Make sure there is less then a full tank of fuel before removing the bolts and lifting unit off of the seal. 3. Maneuver the assembly around as needed to lift the sender unit,and float rod assembly out of the tank.This can be done without removing the gas tank 4. Take the unit to a clean working area and dry off before working on the sender. 5. Take a small screwdriver flat blade and gently pry off the sender cover side housing. Be careful not to break the 3 metal tabs securing the cover. 6. Now remove all rust particles and loose debris trapped in the sender unit. Spray clean the mechanical wiper arm with an electrical contact cleaner. Using an ohm meter you can measure the resistance at the output terminals. Raising the float 0 ohms and dropping to empty open circuit.The wire wound resister varies from 0 to 330 ohms. 7. In my situation the wiper arm had to be gently bent to add tension so a better contact could be made. I even found the resister bowed in the middle and had to bend it back in to position. 8. When your satisfied with your repairs you can re attach the side cover and plug the sender back into the wiring harness,turn on the key and test your gage before re installing in the tank.Vary the float level and watch your gage indication change. Make sure your float is good before re installing. P/S For your comfort there is a small voltage/current flowing through the wiper arm from the fuel gage. So if your gage arc's while setting on 4 gallon you won't feel a thing. A new meaning to the term After Burners.

-

Periodically I fill the tank on the way home, and the next morning the garage smells of gas. Ride 30-50 miles (about a gallon used) to work and the next several days and nothing smells anymore. It sat full for the last few days and gave me a chance to track it down. It was a slow leak so just have to find the wet spots. Sounds easy enough. Originally thought I had a oil leak in the rear shock area, the lower shock links were crusted in black dirt, and the puddle under it represented oil, rather than gas. The gas washed the old oil and dirt down to the floor and evaporated off. Once I cleaned things it was clear gas alright. Finally started pulling hoses, cleaning under the tank, shining a flashlight everywhere, entire bottom of tank area was wet and dirty, no one place. petcock area was dry. Finger on the rear plastic fender next to the shock was wet with gas. Had to be from up top. Feared a rust hole or broken seam at the top of the tank somewhere. Looking through parts drawing for the tank, I saw the fuel sender under the seat. Forgot all about that. Doh! Pulled the seat and it looked dusty and dry. Nto wet like the area further down the fender/rear of tank. I filled the tank to the top and then looked and sure enough, s small weeping spring appeared on the fuel sender. The center nylon insulator sealant is falling off and gas is welling up around it. Plan to drain the tank some and pull the sender out and drill out the riveted asembly, reseal, and re-rivet if possible. Pulling the seat first would have saved much time. - Mike