Search the Community

Showing results for tags 'inside'.

-

Anyone try this yet? http://www.shoplet.com/RealTree-RT17MLAF-AntiFog-Cleaning-Kit-17mL/KLCRT17MLAF/spdv?ci_src=17588969&ci_sku=KLCRT17MLAF&ci_gpa={adtype}&ci_kw={keyword}&gclid=CK6mhaGliMMCFQwaaQodvAoA_Q&rtop=1 I picked up some at Walmart for $6 something for the inside of my full face visor. It also says it repels water and dust?

-

I know we have a lot of different craftsmen and professions here on the site. I have a question for the builders here. I have a 30X40 metal building that I use for a garage, it has a 20X30 upper loft type area. The weather down here in the Houston area has been crazy, 75 one day 45 the next. The humidity is crazy as well. What is happening is it's literally like it has rained inside the garage. The floor is soaking wet and has small moisture puddles on the floor, everything is sweating. It has a metal corrugated roof and there is obviously no venting of it. What do I need to do, to stop the sweating inside the garage. I am thinking of spray foaming the inside ceiling, I know the heating and cooling is creating condensation and I need to get some sort of vapor barrier. Any words of wisdom from y'all in the know would be greatly appreciated. Here's a few pics of the garage also.

-

Our Christmas Day is over..... we had 104F :scorched: Had to move the family inside. We will have over 100F for the next few days

-

When you've stopped at a restaurant or a gas stop/pee break .... in other words, you've left your bike unattended to go inside a building for a period of time ... 10 min - 2 hours or so.... do you lock your helmet on the helmet lock, do you store it inside the trunk, do you take it in with you, do you leave it on the seat or hanging from the mirror or something?

-

I'm fixing to replace my slave assembly pretty soon, getting tired of topping off my clutch fluid every 2 weeks or so. I want to have everything ready so I ordered a new slave, which looks like it has the piston and spring inside (big wad of grease inside). I can't find if there is a gasket for the middle drive gear? Do y'all use permatex or am I missing this gasket in the parts diagrams somehow? Thanks in advance

-

Just a heads up for anyone with a diesel engine... It seems what the gov. did to our gasoline, they are doing to our diesel fuel. My injector pump on the 230 Massey freguson started leaking. I took it off and went to Mountaineer Diesel in St Albans WV. Can you guess what was the first words out of his mouth were? You got it... they are putting things in the fuel that are literally eating the inside of the diesel pumps out.... same as what ethanol is doing to all of our carbs... Who is making these decisions anyway? Going to cost me +600 for a rebuild and I'm seeing RED!

-

I've always considered myself a pretty good mechanic. I'm a commercial / industrial HVAC tech, and I'm one of the better one's you'll come across. This isn't just my ego talking, it's confirmed by the respect I get in the National company I work for, as well as my piers in my Union Hall, as well as those in my local area who know me. I think I can figure out anything, fabricate anything, and repair anything. Every once in a while I need to be put in my place. This old Venture is trying real hard to do just that. (87 Standard) I've been following this site for about 4 years now, and am doing many of the things that I've read that others do to their bikes, and am finding out just how difficult many of these repairs are. Kudos to all of you, and thanks for all the great advice / info I've gotten over the years, and you have my utmost respect for making them sound so easy. I don't get a chance to ride nearly as much as I'd like to, since with my trade, I'm usually working long hours / 6 days during much of the prime riding season, and this year has certainly been no exception. I'll be going on a road trip with friends at the end of August, typically putting 1,000 miles + over the 3 day trip. I know that doesn't sound like much to most of you, but for me it's a bit of an event. In any case, I'm having an issue that caused me to break the bike down somewhat and I figured it'd be a good time to play catch up on some of the things I should have done in the past. What I've done over the past two weeks, in the evenings after work, when I've been able to get home before 9:00, is to replace the carb diaphragms, all of which had small holes. That was the only easy task. I also replaced the spark plug wires, which wasn't too bad, but the right front one was a PITA. I also changed the final drive fluid, but didn't grease the ?spline?....how important is this? The issue that started all this was the exhaust issue where I was getting quite a bit of exhaust flow and noise, some backfiring out of the drain hole on the left side muffler. I thought I had a miss, but after changing the diaphragms and wires, I pulled the exhaust all apart and examined what I could see of the inside of the mufflers and the collector. I saw nothing out of the ordinary. I didn't actually pull the collector off, but pulled the front pipes off and the mufflers off and saw no cracks, nothing loose, no evidence of exterior leaks. I put the front pipes back on and started it with the mufflers off and it seemed to run well. No backfires from either side, and it ran relatively smoothly. Put the mufflers back on and the sound's still there. I'm convinced that the left side muffler has something blown out inside of it. I don't know how the inside of the muffler is configured, and don't understand how it could develop such a problem all of a sudden, but I can think of no other explanation. So that brings my first question.....are there aftermarket mufflers available that will fit this bike, or does anyone know where I can find a good used replacement. Second question is with the clutch slave cylinder. It's been leaking for a couple of years now, causing me to refill the reservoir once or twice a season. I want to rebuild it, but it seems to be tucked in behind the ? output ? casing, making access difficult. If I pull the two bolts that hold it, how difficult will it be to remove and rebuild? If I can get the muffler situation resolved, and the slave cylinder rebuilt, all I should have left to do is to change out the brake fluid (never been done and looks nasty in the window) ...and I'll feel comfortable that I've done my due diligence to keep this old beauty maintained. Any advice with these issues from those of you "in the know" will be much appreciated. I know this was long winded, thanks for staying with me to the end.

-

Looking for recommendation for trunk rack top bag....on the rack not inside...

-

Current temp is 104* according to my eletric temp gauge outside my garage. Inside it's 99*. Weather.com says 101* for this area. Next to nothing is getting done today with most of it spent inside with the ac running. I did build a new shelf along one wall in the garage for the extra goodies I'll pick up eventually from Denny for the 83. Probably do that when we get back from the NY rally. At least temps shopuld be coming down some later in the week. Sure hope so cause temps like these are rough trying to enjoying any riding. Larry

-

Well, you don't need the weatherman to know it's HOT outside!!! Today I did a complete brake job on the wife's Monte Carlo to include new pads, rotors, and hardware in 90+ degree heat. Thank God for air tools!!! Took a break after each wheel by coming inside and enjoying the air conditioning, we have it set for 70 degrees inside. I also have ice cold water, soda pop and iced tea and of course beer!! We are spending our evenings outdoors and put a fan inside the gazebo and watch TV ouit there! So, the questuion is, what are you doing on these hot days and how are you keeping cool??

-

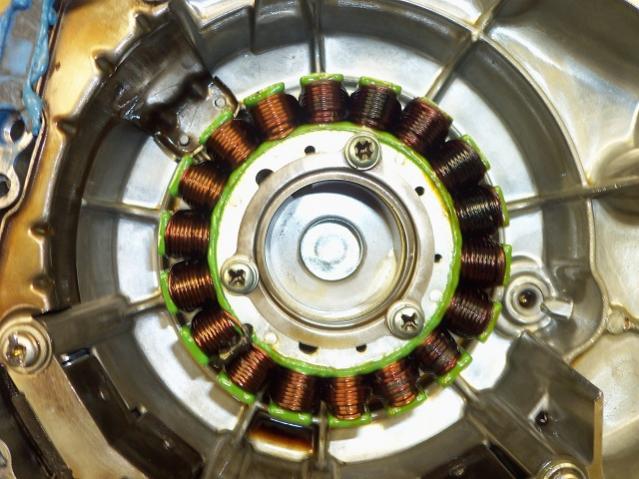

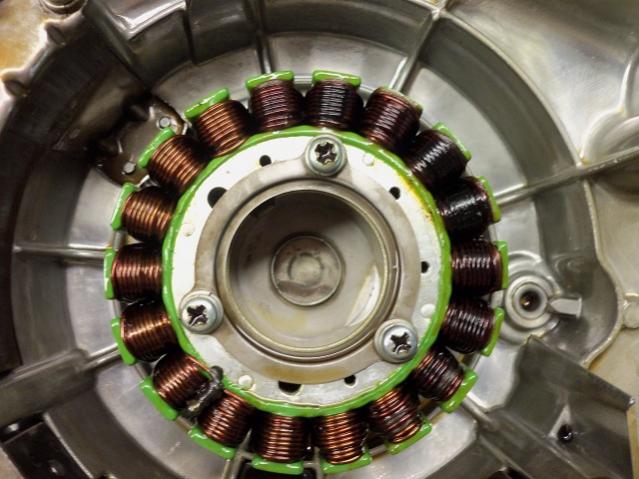

Stator info and cooling kit

bkuhr posted a topic in Venture and Venture Royale Tech Talk ('83 - '93)

Due to difficulty of reading the technical bulletin in the back of the parts manual in the library, I retyped the two bulletins pertaining to the stator cooling kits. Reddevilmedic with burned coils from 1-7 o'clock, does not appear to be lack of oil cooling mentioned in TA, but please make sure your outside baffel is in place under the inspection cover. The inside baffle on the stator looks correct, but there is no mention of ANY washers. Practice states stator screws are red locktite, and hand impact installed. Also I can't not see the wire (shaft 1) inside the bolt hole, pretty sure I could on mine. Stick a small wire in the hole and feel for shaft 1. 1 final interesting note, is I think I count exactly 6 burned coils, exactly 1/3 of the 3 phase stator. Possible for some reason you have one of the three phases overloaded. As the stator is directly wired ONLY to the regulator/rectifier, this leaves the options for overload limited to the RR ac volt side or the 3 white ac wires. If not already done, I suggest you remove the 3 pin connector between stator and RR. Also do the diode ohm test on your current RR. If even doubtful don't use it on another, 3rd, stator Would strongly suggest to get a clamp amp meter. When you get all back together, test each white wire with clamp meter. They should be about the same amps. Harbor freight has a couple cheap ones should workfor this test: http://www.harborfreight.com/catalogsearch/result?q=clamp+meter 69166.doc 69167.doc -

I read the VR tech article but it seems to have a lot missing, particularly when reinstalling. If my memory serves me correctly, although probably incompletely, there are quite a few hints or tips scattered around the thousands of threads on this forum thatt I don't recall the details and can't seem to find. There is something about: - using Locktite but was it the red stuff or the blue stuff? - what about torque on the 3 inside bolts and the 2 outside ones? - using a spray gasket remover instead of a scraper? - properly aligning the shift shaft or it won't work after getting it all together - the washer that fell out when I pulled the stator cover off? It has a lip on the inside edge and a couple of bends that would work like a compression spring. Which way should it go in? - before sealing, is it better to just pull the new wires through the case grommet in place or remove the grommet from the case first? There may be more but that is all I can think of now. Only 5 days before I want to leave for Nelson Kruzen the Kootenays. No pressure.

- 24 replies

-

- compression

- grommet

-

(and 3 more)

Tagged with:

-

While riding with a friend in his pickup I noticed he had a radar detector. It was plugged in but on the transmission hump and facing the passengers door. " Fat lot of good that is going to do" I thought. Then it went off and a minute later we went through a radar trap. A fluke I figured. Then it went off again and a police cruiser passed us going the other way. Then a few minutes later it went off again and stayed on. I finally spotted a cruiser about three cars behind us. Obviously when you get zapped with the radar it bounces around inside the cab a few times. What is the cumulative amount of radar you are exposed to? Around here you can go through 3-4 traps in a day. Does anyone know of a study which takes in the total effect of multiple zappings inside the cab?

-

I just found this trunk crack on my 91 VR. It is hard to see. It looks like a stress crack from age and hardening of the plastic, for there is nothing around it that indicates it got hit. And I have not loaded it much at all. I may have purchased it that way, only at that time I may have missed it. The crack does definately stop my fingernail from going over the crack. I dont know what those white spots are for they are not on the turnk. The paint on the trunk looks like the day it came off the show room floor The crack is also felt on the inside. Also the crack starts right dead center on one of the screws that hold the trim on. My options are 1) Just ignore it and hope the crack does not travel father 2) Take it to a body shop for an estimate 3) Buy a used trunk and have it professionally painted to match. 4) Your suggestions

-

I put a new rear tire on last week and found that the inside of the rim was coated with some sort of black stuff that had left corosion on the inside the rim so I cleaned the rim off with a brass brush and soap and water and there were some pretty good pits. Everything seemed ok after the tire was mounted but after the first ride it is leaking about 30 pounds a day. I am thinking maybe if I break the bead and reset it that may take care of the issue, I had thought about ride on but I was told it was no good for sealing around the rim. If this does not work does anyone have a spare rear wheel for a 2nd gen they would part with cheap?

-

Need advice to repair or a replacement source for the 'lead switch assembly' in the rear brake reservoir. First time working on a brake issue on this bike so I'll elaborate as best as can with what I've found so far. Inside the reservoir, this assembly has a hollow plastic post with a C clip stopper on the top. The C clip prevents the float from slipping off the post. The float moves freely and stays at the top when fluid is topped up. It appears this float has a magnet attached to the inside circumference of itself that should keep the relay inside the post operated (N/C) for continuity back to the CM. ( I compared this with the front reservoir which works properly. Measured 0 ohm short) With the assembly removed and a meter across the two leads, the float in place and tapping the post with finger a few dozen times, the meter shows intermittent to no continuity. Likely corroded or dirty relay contacts? Is it possible to remove the relay from inside the post without destroying the two wires? I got the rubber/grout collar off but couldn't get the relay loose to pull it out. Could only find this OEM assembly part on-line as discontinued. Everything is reassembled and mechanically works at this point, but the two leads towards the CM are temporarily bridged to keep warning light extinguished. Any help would be appreciated, thanks in advance. (what a better way to spend half of the long week-end eh)

-

Hey.. how do I remove the bags from an 83 without the key ? The bags are open, but seem to be locked on the bike. I need to get the bags off so I can remove a hitch from one of my part bikes. I don't want to damage the bags. Do I drill off the locks inside ?

-

Two Irishmen are sitting in the pub window seat, watching the front door of the brothel over the road. The local Methodist pastor appears, glances around and quickly goes inside. "Would you look at that!" says the first Irishman. "Didn't I always say what a bunch of hypocrites they are?" No sooner are the words out of his mouth than a Rabbi appears at the door, furtively looks about, and goes inside. "Another one trying to fool everyone with pious preaching and stupid hats!" They continue drinking their beer roundly condemning the vicar and the rabbi when they see their own Catholic priest knock on the door. "Ah, now dat's sad." says the second Irishman. "One of the girls must have died...

-

http://www.jpcycles.com/product/3300773 You will also need to get hose at your local auto shop I used vacuum line get 5 Feet the inside die was just enough to be able to push the two wires through. [ATTACH]64242[/ATTACH] [ATTACH]64243[/ATTACH] Get 5 feet of whatever hole you want, I use vaume hose [ATTACH]64244[/ATTACH] remove the 8mm nut [ATTACH]64245[/ATTACH] make SURE you have the bottom nipple down and drill at the top [ATTACH]64246[/ATTACH] [ATTACH]64247[/ATTACH] Break all of the old lens out (watch your eyes) [ATTACH]64248[/ATTACH] [ATTACH]64249[/ATTACH] [ATTACH]64250[/ATTACH] I used this type sander to make my surface flat Your just removing the outside edge lip. [ATTACH]64251[/ATTACH] [ATTACH]64252[/ATTACH] [ATTACH]64253[/ATTACH] Now cut your hose in half 2.5 feet, spray WD 40 inside the hose on both ends and pust the wire through. it will go with no problem. [ATTACH]64254[/ATTACH] IMPAORTANT: Make sure you have your wires through the back plate then then run the wire through the hose see photos. [ATTACH]64255[/ATTACH] [ATTACH]64256[/ATTACH] Clean off the left over WD40 with cleaner [ATTACH]64257[/ATTACH] Now peal off the 3M backing and I used GOOP and file all around inside and up around the black vac line. [ATTACH]64258[/ATTACH] [ATTACH]64259[/ATTACH] Then clamp together, wait about 30 minutes and your ready to use. [ATTACH]64260[/ATTACH] [ATTACH]64261[/ATTACH] Run the hose at the same area as the front brake hose is routed. and up to the the wireing in the front cowl.. I will most tie into the cowl area you could also tie into the running lights area as well. [ATTACH]64262[/ATTACH] [ATTACH]64263[/ATTACH] [ATTACH]64264[/ATTACH] Use a hose of your chioce that the wire just will fit into. [ATTACH]64265[/ATTACH] LET THERE BE LIGHT. Any Qustions feel free to email or PM me. Enjoy, Jeff

-

My truck is suffering from a bad case of chemical weight reduction. The rust is coming thru from the inside in areas that there is no access to the inside. I am not a body man by any stretch of the imagination. I am not looking to restore it to like new appearance just to stop the cancer and cover the holes to keep it from getting worse and stop the whistling in the wind. I was looking at POR15 or Rust Bullet. But I have no idea of how to get it to the insides of the areas that are rusting. The rust has created plenty of holes stick things in there. Is there some kid of a wand spray gun that can be had for not to much cash? I was then going to fix the areas with glass cloth and epoxy resin, followed by some Bondo to smooth it out a little before I buzz bomb it.

-

I just bought an 88 venture which the previous owner said only sat for a month. Well, when the bike would only run on chock, i took of the carbs to clean them. Needless to say they were interesting inside. Now that I have them cleaned out, was curious to know what I should set the sync screws at so I can at least get it started and sync them properly. Any inout is greatly appreciated.

-

I am really tired of sitting on my bike and rocking it back and forth to fill the tank to the top. I am thinking of drilling some holes in the inside sleeve of my gas tank. The sleeve is solid and goes into the tank about 2 inches from the inside edge of the collar. It keeps me from filling the tank that last half gallon unless the rocking ( which looks really ridiculous) and it burps fuel all over sometimes. Anybody else have this kind of experience? Editing because after this posted the threads for this topic came up and I saw the fix and comments from V7 Goose. Don't know why these threads didn't show up on search. BTW thanks V7 Goose, I would have drained the tank, pumped in co2 and drilled it but like your idea much better!

-

See Picture So as the drain pipe comes down the main floor wall from the sink area, it has to make a inward jog so the pip can come inside and down the cement wall into the basement. The leak is all along the circurmfrance of the long verticle basement pipe where it fits inside curved pipe. So what is the best way of fixing it?

.thumb.jpg.176b2ebbe9863175975d94710375c414.jpg)