-

Posts

101 -

Joined

-

Last visited

Reputation

29 ExcellentPersonal Information

-

Name

James G.

location

-

Location

Knox, IN, United States

Converted

-

City

Knox

Converted

-

State/Province

IN

Converted

-

Home Country

United States

Converted

-

Interests

Motorcycles, Guns, Family & God. Guess I'm a bitter clinger.

-

Bike Year and Model

84 XVZ12 Venture Std

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

Time for another update: Before swapping the pickup coils, I opted for the easier ignition coil swap. My backup ignition coils from my parts bike were found to have several cracks, so they were not used. I've purchased used COP coil sticks from a Honda CBR and installed them. The Ignitech unit works just fine with the COP coils, but I installed a section of spark plug wire between a COP and the spark plug...only to find that the miss is still present at idle. The pickup coil will be pulled from the donor bike next.

-

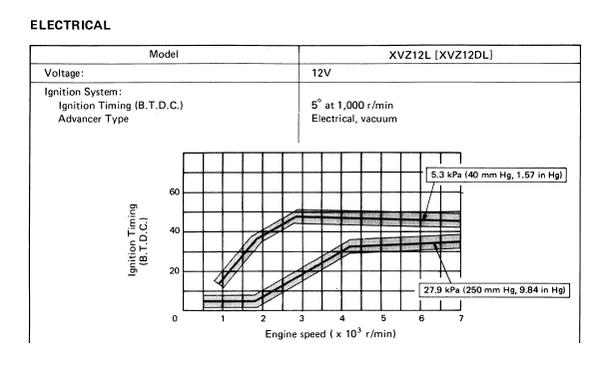

I promised an update, so here it is. I've received the Ignitech unit and installed it. I like this product. It fired right up and seems to have no dead spots...but the miss at idle is still there. I left the TCI unit in place as a backup, in case I ever have problems with the new unit. That leaves 2 possible sources, as I figure it: the pickup coils or the ignition coils. I've got an 86 MKII that has been an occasional donor. A pickup coil swap might soon be under way. I'll also be tweaking the program in the Ignitech unit because it doesn't seem to match the Yamaha manual's timing diagram at all. Mine is setup for use with the original MAP sensor. Does anyone have an Ignitech program that better matches the advance curve in the manual? Even if it's from a different year that won't be plug-n-play, I'd appreciate the chance to see a working advance curve that looks more like the Yamaha design.

-

I was changing my oil this morning and making a mess, as usual. Pouring from the bottle is ridiculous. None of my funnels are the right size and never stay in place. It dawned on my that I could make my own disposable funnel. Roll up a piece of paper into the long slender funnel required. Use and discard...no more mess. Why did it take me so long to figure this out?

-

It's time for a follow-up road report. WOW! That worked much better than I'd expected. That annoying vibration at 35-40 is gone! I'll be using these again.

-

That has been my train of thought lately too. However, just to eliminate other variables...I picked the cylinder that I thought might be considered the "worst" of the 4 and replaced the coil with an extra from my inventory. The coil I pulled out measured within spec at room temp (both primary & secondary resistance), and so did the replacement. The original coil looked good with no cracks or visual defects, while my extra has some cracking along the top of the plastic casing. (I tried to seal it up with RTV prior to installation.) Start her up and the miss is reduced, still there, but not as frequent. What are the odds that all 4 coils are breaking down at the same time? I'm not yet convinced that this is the culprit. I have an Ignitech unit arriving next week and will let you all know how it goes. If the ignition module doesn't do the trick, I'm thinking of upgrading to COPs next. Additional notes: All connectors have gotten treated with dielectric grease before being reconnected. Miss has been present at startup (cold) and when hot.

-

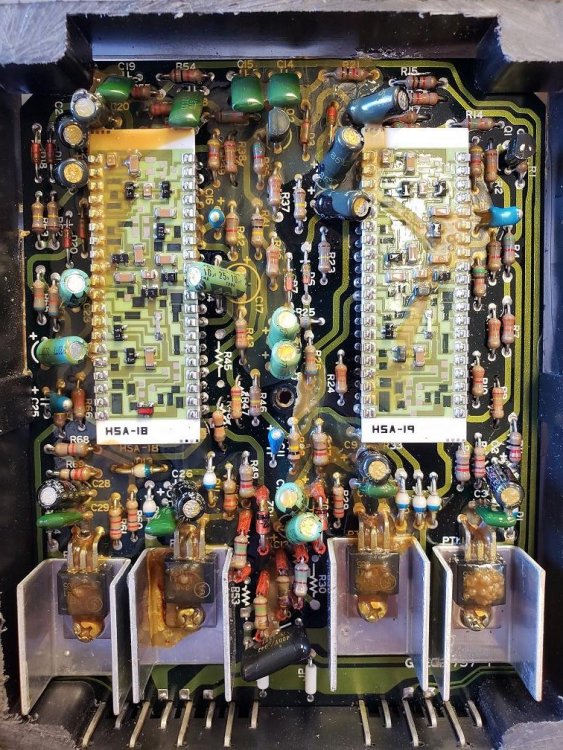

Well I went ahead with the TCI "preventative maintenance". Replaced diodes and discolored resistors. I also removed & examined the ground at the coil bracket, since I was in the area and found it to be clean. Re-install and test to find...no change. The random spark miss on all cylinders is still there.

-

You're correct. There are two oops at that nut. They are merely anchor points for the heat shields though and shouldnt effect the circuit. My question, though rhetorical, is have they always been that way?

-

The conformal coating can be very misleading. It's not evenly distributed and it has a tan brown color. It tends to make a component look burned when it isn't.

-

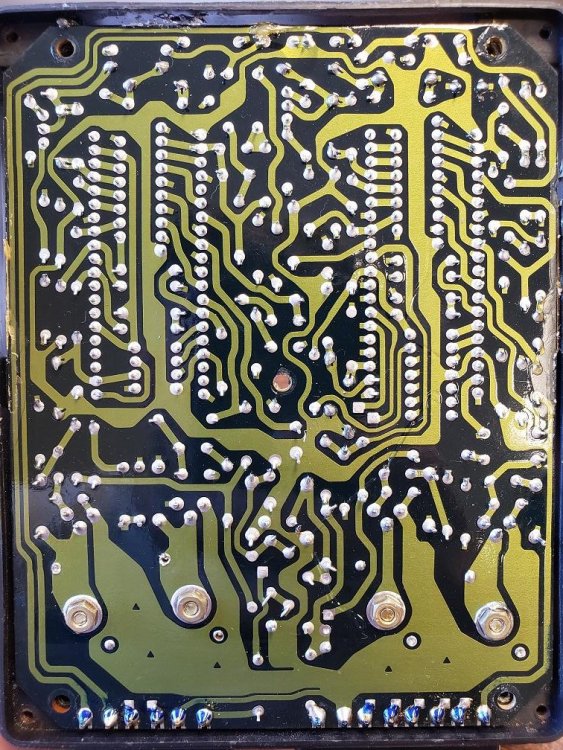

This is the latest update. I'd been putting this off in hopes of finding something else. Nevertheless, I removed the TCI and opened it up. You may notice that it's still in the plastic box. I used the mill to carefully remove a bit of plastic from around the bottom edges of the box and removed the bottom as a plate. (Silicone and/or epoxy will be used to reinstall it...besides it wasn't sealed to begin with.) The diodes look "fine" though we all know that can be misleading. I wish I had a schematic for this board. The only component that "looks" bad is this resistor in the center of the last pic. It appears to be overheating and looks slightly burned. Anyone seen this before? Thanks!

-

I'm installing Dyna beads and thought I'd give a quick story on my installation of the small ceramic beads through the valve stem. I poured the beads into a small bottle with a tapered tip. Remove the valve stem core. Tape the tapered tip of the bottle onto the valve stem. Now Find a small screwdriver and insert the metal shaft into a cordless drill. Any small screwdriver will work as long as it has a knobby handle. Then run the cordless drill and let the knobby handle tap against the rim and watch the beads sift into the tire like sand through an hour glass.

-

I have moved the induction light to each of the 4 spark plug wires and found a sporadic miss at idle each time. I also checked with an old school inline timing light and got the same result. There is a steady series of flashes and then a random pause, with no spark, and at the same time there is a slight change in the exhaust note. Not a backfire but more a momentary hesitation. When I rev the RPM the flashes are so fast that I can't distinguish a miss. It might still be there at higher rpm but I'm not sure. Yes the issue is there both hot and cold. I must admit that I m unfamiliar with the technique you mentioned...would you mind explaining it. Thanks

-

Yes it's got an upgraded blade style fuse holder, and I just checked the connection there. Seems fine.

-

I checked two coils today and found... Primary coils: 3.0 & 3.1 ohms at 90F Secondary coils: 13.3k & 13.2k ohms st 90F My manual says Primary: 2.7 +/- 10% at 68F Secondary: 13.2k +/- 20% at 68F The primaries are at the high end of the range but probably still fine, if I did this correctly. Thanks for the suggestion.