-

Posts

6,853 -

Joined

-

Last visited

-

Days Won

167

Content Type

Profiles

Forums

Gallery

Events

Store

Everything posted by saddlebum

-

A definite maybe for me. getting the time off could be a stumbling block for me. Seems I am too valuable to be allowed vacation time unlike the rest of the employees, who can get time off whenever they want.

-

Thankfully your on the ball @Freebird

-

That's because I am far too busy monitoring the air conditioning unit in my office to get involved with those other issues but they are on my list of things to get around to when time allows.

-

I heard he deliberately detoured around your neck of the woods. Not really sure why, but.

-

There are some real twisted people out there. Maney years ago I pulled into my regular gas station were a car had pulled in just a few minutes before me. The parents and the kids were getting their faces hosed down by the gas station attendant. some jerks thought it was funny to drop a car battery off the overpass over the QEW which hit their car in the center of the windshield.

-

Hey @Marcarl FYI! It's hard work handing out repair orders. 1- you have to pick up the phone and page a tech to the office, 2- you have to lift a piece of paper known as a repair order off the desk and hand it to him, sometimes even explain it to him. ( if your lucky you get time to catch your breath between 1 & 2 ). 3 you got to tilt the chair back so you can rest up for for the next time you have to execute 1&2. Sometimes it gets really rough you have to answer the phone to answer silly customer questions like (when do think my truck will be ready)

-

Today I renewed the insurance and lic plate and rode it to work.

-

They have it down pretty pat so I would say go for it. Ask around and find out who in your area is the most recommended.

-

I did the same on the advice of others before me. Some not all who settled for the basic have said the wish they had gone the extra step so I did.

-

Hello From NY! Just Purchased 1983 "Barn Find"

saddlebum replied to Stream Rider's topic in Watering Hole

I could be wrong but I think it was E4 or E6 but as stated its not a difficult fix if your handy with soldering circuit boards. As far as the actual compressor itself goes I cannot recall ever hearing of one fail on either the MKI or MKII 1st gens. Once you do repair the board add an additional support for the harness were it enters the connector which plugs into the controller and make sure the harnes itself has lots of freedom of movement. Opening and closing the door creates wire movement in the plug which contributes to the cracking of the solder joints. -

I had no choice. I knew If left the rest dirty I would not hear the end of it. But thank you just the same.

-

-

Finally finished the repairs and repaint to the left side and rolled it out of the garage for a trial run around the neighborhood. Tomorrow I hope to get the insurance back on bike.

-

Welcome to the club. I had mine done last year and never in my life could I see so far and so clear and with so much detail. My 1st discovery was that trees had individual leaves they weren't just all green like a kids coloring book. I always had the fear if I lost my glasses whether on the motorcycle out on a horse or backpacking and/or canoeing the back country that I would be in what heck of a bind. Not any more.

-

@skydoc_17 ( but I'll talk to just about anybody! ) just about took you off my friend list. (I still Love you guys! ) but this last comment earned you some brownie points

-

Princess Auto and many marine stores carry blade type fuse blocks that are ideal replacements for the stock glass fuse holder. The retaining clips on those get corroded thin and weak. Try picking out a block with a few extra fuses for add on,s. Also you may want to carefully take the signal switch apart clean and lubricate it with a light electrical lubricant like ACF 50. Park the bike on an old carpet so if anything drops it won't get lost. https://www.amazon.ca/ACF-50-770153100130-ACF50-ANTI-CORROSION-369GR/dp/B016OMGR0E/ref=asc_df_B016OMGR0E/?tag=googleshopc0c-20&linkCode=df0&hvadid=293033137840&hvpos=&hvnetw=g&hvrand=16358521859039373572&hvpone=&hvptwo=&hvqmt=&hvdev=t&hvdvcmdl=&hvlocint=&hvlocphy=9000858&hvtargid=pla-568295715302&psc=1

-

The only progessive springs I have are in use. You may want remove and inspect the anti-dive valves. They can get bunged up with crap due to old moisture ladden brake fluid. Also check out Zedno in kitchener. There is the chance that they have some damaged forks that may contain progressives.

-

Here is a set up I threw together in a pinch to wet set my carbs on the bench any variation of this would work. The key factors are a pressurized fuel source at a steady 3.5 psi (an air tight container with a tube going to the bottom which supply's gas to the carb and a metal tubeless tire valve secured to the top to add pressure ) the clear plastic tubes installed on the drain holes. I have since Used a different set up much more compact and simplified but I have no pics. however the attachment should give you the jest of it. Home made set up for wet setting floats on the bench.pdf

-

new home Picking up the '86 today!

saddlebum replied to Scotty and his Scooter's topic in Watering Hole

As long as you got the leg length to put both feet on the ground it's still one of the best riding bikes out there. BTW it's worth becoming a full member here not just for tech savvy but the social aspect as well. Thanks to Freebird it is one of the best forums on the net. -

Looks super. I am totally impressed.

-

Even if it's without the bike - let us know. Great excuse (not that we need one ) for a meet and greet.

-

1681986031982_VID-20230419-WA0001.mp4

-

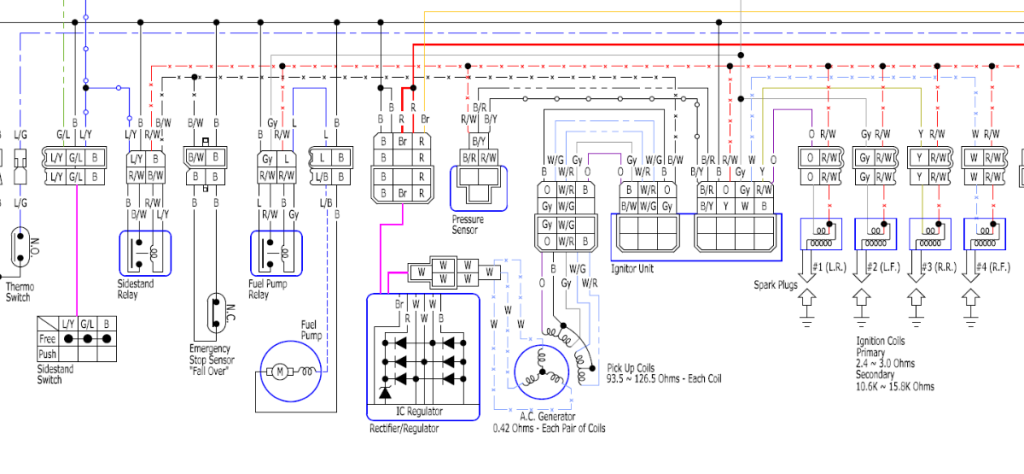

Marcarl is correct. You should have constant 12v to each coil, the ground side of the coil is individually controlled by the TCI. If you look at the schematic you will see that the there is a red/white wire that goes to the 8 pin connector at the TCI , each coil, pressure sensor, fuel pump relay and side stand relay. With ign on you should have 12 volts at each connection point. You should also have constant ground via the black wire 0n the 8 pin plug to the TCI , fuel pump, fuel pump relay, fall over sensor switch, With all the fall over switch, side stand switch and relay all in the normal run position you should also have ground were the black/white wire connects to the TCI at the 6 pin plug. Disconnect the 6 pin plug at the TCI and down by the frame at the stater Which goes to the pick up coils within the stater housing. With an ohmmeter check that you have continuity from the pin on one connector to the pin on the other connector for every wire. Also check the condition of the connector at the stater it is not uncommon for these to turn green in which you would either replace the connectors or just cut them out and hard wire the ends together. If this tests OK perform an ohmmeter test on the pick up coils themselves. With the pickup coil 6 pin connector disconnected check resistance for each coil by connecting one test lead to the black wire and with the other test lead touch each of the other wires you should get ( approx 93.5 to 126.5 ohms ) for each one any one that does meet this spec indicates a pickup coil fault of some sort. Open line reading is an open connection or broken wire to its related coil lower than 93.5 or full continuity would indicate a short of some type.

-

You of all people should it's about the story. Whether or not it's the truth, is totally irrelevant.