-

Posts

3,621 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Store

Everything posted by Prairiehammer

-

Swingarm question

Prairiehammer replied to Great White's topic in Venture and Venture Royale Tech Talk ('83 - '93)

The 1986 swingarm will bolt up to the 1983 frame however, the '83 rear brake caliper bracket probably will not fit the '86 swingarm (different mount styles). The 1986 driveshaft is longer/shorter than the 1983 driveshaft; that indicates that the swingarm lengths are different as well. (Make sure you get the driveshaft for the V-Max final drive that you want to put on the 1983, 'cause the 1983 driveshaft won't work). After some deliberation and retrospective, I can't recall ever seeing a MKII/V-Max/Second Gen final drive on a MKI. -

The TCI numbered "TID14-17" (26H-xx) is for a 1983 XVZ12TK/TDK (there was no 1983 XVZ12 imported to Europe). Your XVZ12TD-47G should have the TID14-34 (41R-xx) TCI. What is the complete VIN (frame number)? Is there a manufacturing date anywhere on the label? IS there a white label with vehicle identification on the lower frame rail beneath the brake pedal?

-

Pretty cool, Eck! At the risk of hijacking this thread (but you brought it up in a way) what are the extra grips about? Does the right one rotate with the throttle or is it stationary? I see the adjustability of the extra grips, looks very comfortable. Do you ever find the extra grips get in the way of normal operation of the bike? @cowpuc would prolly mount some knee pads to those extra grips; to provide a more comfortable "knee steering" situation.

-

Been having problems getting our site to load, any one else?

Prairiehammer replied to cowpuc's topic in Watering Hole

WOW! 2344ms to load? Ping= 36.8ms? THAT seems really slow. I pinged Google and got this: C:\Users\Kevi>ping google.com Pinging google.com [216.58.216.78] with 32 bytes of data: Reply from 216.58.216.78: bytes=32 time=20ms TTL=55 Reply from 216.58.216.78: bytes=32 time=17ms TTL=55 Reply from 216.58.216.78: bytes=32 time=20ms TTL=55 Reply from 216.58.216.78: bytes=32 time=16ms TTL=55 Ping statistics for 216.58.216.78: Packets: Sent = 4, Received = 4, Lost = 0 (0% loss), Approximate round trip times in milli-seconds: Minimum = 16ms, Maximum = 20ms, Average = 18ms When I pinged Venturerider.org just now, I got a much better result than earlier. C:\Users\Kevi>ping venturerider.org Pinging venturerider.org [67.222.3.45] with 32 bytes of data: Reply from 67.222.3.45: bytes=32 time=45ms TTL=51 Reply from 67.222.3.45: bytes=32 time=47ms TTL=51 Reply from 67.222.3.45: bytes=32 time=48ms TTL=51 Reply from 67.222.3.45: bytes=32 time=50ms TTL=51 Ping statistics for 67.222.3.45: Packets: Sent = 4, Received = 4, Lost = 0 (0% loss), Approximate round trip times in milli-seconds: Minimum = 45ms, Maximum = 50ms, Average = 47ms -

Been having problems getting our site to load, any one else?

Prairiehammer replied to cowpuc's topic in Watering Hole

I've been gone for a few days (Leaf Looker) and just tried to get on for the first time this morning and YEAH, @cowpuc it took about 90 seconds for the home page to come up and another 2 minutes of "spinning wheel" before this thread came up. I am also running Windows 7 and Firefox (v.41.0). The only site that I have had issues with is Venturerider.org. Even before this extraordinarily long wait this morning, I've noticed a decidedly slow loading on VRO lately. I've had to refresh fairly often to get to another thread. -

Been having problems getting our site to load, any one else?

Prairiehammer replied to cowpuc's topic in Watering Hole

I've been gone for a few days (Leaf Looker) and just tried to get on for the first time this morning and YEAH, @cowpuc it took about 90 seconds for the home page to come up and another 2 minutes of "spinning wheel" before this thread came up. I am also running Windows 7 and Firefox (v.41.0). The only site that I have had issues with is Venturerider.org. Even before this extraordinarily long wait this morning, I've noticed a decidedly slow loading on VRO lately. I've had to refresh fairly often to get to another thread. -

As for the constant "search" it may be just a button stuck. Try a bit (a little bit) of WD40 on the button.

-

That IS some "significant" damage. I wouldn't try to repair it. There is a matching 1983 maroon saddlebag on eBay right now. http://www.ebay.com/itm/1983-Yamaha-Venture-XVZ12-XVZ-1200-Y319-right-side-saddle-bag-with-key-/231175684861?hash=item35d32502fd&vxp=mtr

-

gasket kit?

Prairiehammer replied to Great White's topic in Venture and Venture Royale Tech Talk ('83 - '93)

Sirius Consolidated (a Canadian company) has a "complete" engine gasket set for $149US on eBay, includes four exhaust port gaskets, too. It does not have "oil seals", though. EDIT: Go to their website where the same kit is $130.90US. http://www.siriusconinc.com/pro-detail.php?pid=&product_id=121166 http://www.ebay.com/itm/YAMAHA-V-MAX-VMAX-VMX12-VMX1200-XVZ12-VENTURE-ROYALE-ENGINE-GASKET-SET-1983-98-/161748938640?hash=item25a8fcef90&vxp=mtr -

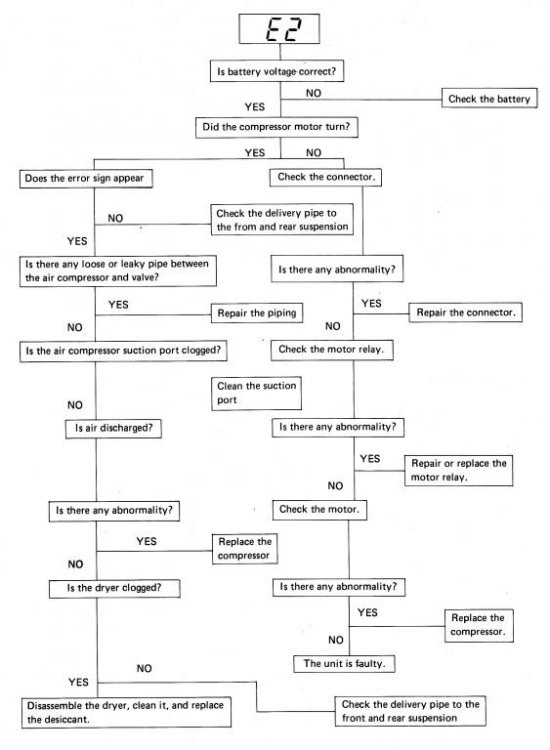

Here is a write up about overhauling the CLASS compressor. The CLASS was exhibiting the "E2" error prior to overhaul. CLASS System Compressor Ring Repair I was having problems with the CLASS air compressor on my '88 Royale. From 0 psi, it would pump the rear shock to about 52 psi before giving an error E3, “compressor on too long”. Repeating the attempt to increase pressure resulted in about a 1 psi increase before stopping with an E2 error, “air pressure not increasing”. It appeared that the compressor was running, but could not produce enough pressure to satisfy the CLASS computer's diagnostics. When a reciprocating piston engine loses compression it may be caused by a blown head gasket, leaking valves, worn piston rings or internal damage. Disassembly of the CLASS compressor was in order to determine the apparent lack of compression. Removing the assembly was pretty easy. There are three electrical connectors to remove, one to the compressor motor, one to the bleed valve and one to the manifold assembly. Remove the banjo fittings for the front and rear air lines. (Caution: reduce the pressure to 7 PSI before doing this). Then the whole compressor/valve/drier assembly lifts out off the studs that the cover attaches to. Next, remove the air line from the compressor to the drier. Disconnect the fitting at the valve, then loosen the clamp for the drier and remove the air line fitting on the drier that goes to the compressor. With the air line now disconnected, remove the compressor from its mounting bracket. Now, one can fit a wrench to remove the air line. Clamp the compressor in a vice, with the compressor head facing up. Remove four head bolts/screws and remove the head. Two thin pieces of metal form a reed valve at the intake port. Remove them. The body of the compressor contains a sintered metal insert that acts as a cylinder. The cylinder head seals to that insert via an O-ring. Re-orient the compressor in the vice so that the motor is straight up. There are six screws facing upwards. The middle two secure the motor to the body and do not need to be removed. I removed the outer four screws and separated the compressor case. The motor side has a simple gear reduction from the motor with a small crank pin sticking out. The piston and rod will be lying in the bottom half of the case. I pulled the cylinder/piston assembly from the head and pulled the piston from the cylinder. After washing everything in solvent, I could see no damage. The piston has a single Teflon looking piston ring on it. The piston ring didn't seem to stick out much from the skirt. I was confident that Yamaha did not sell a replacement. I wondered how I could make the ring thicker. Some oil rings on automotive engines are multi-piece. They have a wavy steel spring that fits in the groove, and then the oil ring sits on top of that wavy spring. The spring presses against the oil rings forcing them outward. So, I took a piece of paper and cut a string 1 7/8" long (the circumference of the piston ring groove) by 1/8", the width of the ring) and placed it in the groove and then put the ring on top of it. I slid the piston back into the cylinder. It was too tight. I measured the thickness of the paper as .005". I went on a hunt and found some thin tissue paper. It measured just a touch over .001". I cut a strip from this tissue paper. I put the piston in the cylinder and felt a little bit of resistance, not too much. I lubricated the piston with a very light coat of Vaseline and replaced the piston in the cylinder and reinstalled the cylinder in the compressor housing. I smeared molybdenum grease on the crank pin and a thin coat of RTV on the mating surfaces on the compressor housing and reassembled the compressor, making sure that the crank pin went into the piston rod. I cleaned the reed valve inserts as well as the head. I installed the reed valve inserts in the recess at the top of the cylinder, observing that the alignment notch was properly oriented. I cleaned the head and put a thin coat of Vaseline on the intake port and on the O-ring. I couldn't readily figure out how to clean the exhaust port. There is a bolt on the top of the head that presses on a spring that closes the exhaust port. I removed the bolt and the spring, but the valve stayed in. I put the head back on and tightened the screws. I reassembled everything and installed the assembly on the bike. I flipped the ignition to the “accessory” position and depressed the “H” (high) button. The digital readout indicated that the compressor pumped up to 70 psi and shut off; as designed. I bled the pressure down to 43 psi. Again, commanding high pressure, the compressor pumped back up to 70 psi indicated with no errors. Since I have aftermarket Progressive® springs in the front forks and like the handling with no air pressure in the forks, I left the front air line disconnected. I capped that air line by placing two rubber washers, one on each side of the banjo fitting, and bolting them together with a 1/4" bolt and two steel washers. That will keep any dirt or moisture out of the air lines. On the valve side, I bought an M8x1.0 bolt and cut it short, probably 15-20mm and screwed that into the valve body, seating it against the o-ring. I saved the banjo bolt in the event I wished to return the CLASS function. The whole operation took less than an hour and didn't require any special tools, other than a micrometer to measure the paper ring spacer. Larry Piekarski

-

gasket kit?

Prairiehammer replied to Great White's topic in Venture and Venture Royale Tech Talk ('83 - '93)

I suppose it depends on how solvent your bank is. "Complete" engine gasket kits are in excess of $200US. Then there is the "complete" clause...not many are "complete". Some are sufficient, short of head gaskets, but others are woefully incomplete. Just curious: why are you in need of a "complete" engine gasket kit? -

What symptoms are causing you to think the START button/switch is bad? There were several right hand switch gears available on eBay (used, of course). Enter "XVZ start" in the eBay search box. But, the START switch is fairly robust and simple and not prone to wearing out. It IS prone to dirty contacts, though. Gary Dinges produced an excellent tutelage on cleaning the various switches on the handlebars. Perhaps as a Trial Member, you are not allowed access to all the Technical Library has to offer. If you are allowed, check out the First Generation Technical Library. There you find how to disassemble and clean the START switch. And @bongobobny, the START button has never been red. Black or gray.

-

Looking for a discontinued part.............

Prairiehammer replied to DragonRider's topic in Watering Hole

I took some pics of the fairing edge trim when I was refurbishing the '91. The one had come loose (original double sided tape). -

Lots of folks are confused about that punch mark above the middle gear. Yamaha told the dealers and mechanics to make that punch mark when they had performed the stator cooling kit installation. There was no directive to make that mark when the second gear repair was made. The stator cooling kit was a warranty and "recall" deal. There was no "recall" for the second gear problem, thus no Yamaha mandated warranty repair. M84-025 Stator Cooling Kit Installation.pdf

-

All the 1983-1987 First Generation Venture Handlebars (26H-26112-00-00) are the same, irrespective of year, sub-model or right or left. I believe that the 1988-1993 Venture handlebars will also fit, but those years carry a different part number (26H-W2613-00-00).

-

Run Off VOTING for 2016 International Rally Location

Prairiehammer replied to Freebird's topic in Watering Hole

-

All this recent talk about motor mounts, causes me to report on my very recent experience: I have been seriously disappointed with the handling of my 1991. It wandered on straight stretches of highway and fell into curves causing constant correction. It seemed any pavement irregularities caused the bike to hunt. I adjusted tire air pressure, CLASS air pressure, shock preload, steering head torque, greased the rear suspension links (though, it was apparent that had not been done for quite awhile. Half of the Zerks would not take any grease.), ad nauseum. Purely by accident, as I was adding oil during an oil change, I noticed that the right rear motor mount bolt was hanging way out! Closer inspection showed that the engine and frame had been moving in relation to each other for quite some time. I had to lever the engine up a bit to restart the bolt into the threaded frame boss. And then torqued the bolt to spec. While I was at it, I checked the torque on the lower removable frame rail. All the bolts were loose or below torque specification! (These are the Allen head bolts joining the main frame to the lower removable frame rail). Yamaha had a tech bulletin issued back in the day, advising that the frame bolts be checked for proper torque. I suspect that none of the previous owners of my bike had ever done that. I took the '91 on a trip the next day. Two up laden and pulling a trailer and the handling was amazingly better. And a persistent but unexplained "clunk" I had experienced previously was gone. Bottom line: check the torque on your motor mount bolts AND THE FRAME BOLTS!

.thumb.jpg.7adc16b92ec465a819e11c80d3ef9dd0.jpg)

.thumb.jpg.518131cef4c4f23f33e67d3ae17f9a3c.jpg)

.thumb.jpg.cb94fd5460d01624bced4fbb319b8626.jpg)