-

Posts

3,621 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Store

Everything posted by Prairiehammer

-

No. Pull the carbs a bit out the left side. Run the throttle adjust nut at the handlebar in to get some free cable. Loosen the adjustment coupler right at the carb all the way. Pull that cable housing up from the carb cable holder and slide the cable through the slot in the carb mounted holder, there's enough slack to get it out of the holder. Then you can tip the carbs to see how to disconnect it. Roll the carbs and take the cable off. The choke is easy; loosen the clamp and slide the cable free.

-

Former VentureRider.org members said to say HI!!!

Prairiehammer replied to cowpuc's topic in Watering Hole

-

head water jacket plug.

Prairiehammer replied to Black wing's topic in Venture and Venture Royale Tech Talk ('83 - '93)

That part is available here for $17.18. http://www.boats.net/parts/detail/yamaha/Y-26H-12469-01-00.html On eBay here: http://www.ebay.com/itm/Yamaha-26H-12469-01-00-26H-12469-01-00-JOINT-1-/182098493569?hash=item2a65ea8081 -

One does not have to remove the upper fairings or the battery or the battery box or the coil pack rack to remove the TCI. I have removed and relocated the TCI on all three of my Ventures. Remove the side covers. Remove the top cover. Remove the triangular "chromed" pieces that attach to the radiator cover. Optional. Remove the lower fairings. Optional. Remove the air box. Use a #3 Phillips or #3 JIS hex screwdriver insert, one inch long. Place the screwdriver insert into a ¼" socket. Run a length of electrical tape around the socket and insert to keep the insert from falling out. Use a shorty ratchet with the socket. Easy peasey.

-

-

For years, maybe decades, I've commented on the huge expense incurred in this country, just to get a mowed lawn. Not counting the cost of the expensive equipment. Not counting the huge expenditure in time/labor. Not counting the cost of repairs and maintenance. Just counting the cost of fuel: 800 MILLION gallons annually at $2.50 gallon equals 20 BILLION dollars. Seems like we would be better off with Xeriscaping. Or sheep. Or meadows. Or ...

-

Canada to Cancun on the 250$ Venture - The full ride report

Prairiehammer replied to jfman's topic in Watering Hole

Oh, so close (to getting this famous bike's VIN). But the last four digits of the displayed VIN is illegible. Now that you have completed your trip, would you PM the VIN? Thanks. And as a not insignificant aside: you are a true adventurer. My hat is doffed to you. -

Yes, it could be, but personally, I would suspect fuel delivery. When you say the rpms drop to "zero", do you mean the tach quits reading any rpm or do you mean the engine actually stops rotating? If the tach drops to zero and the engine is still running, then yes, that is a tell tale of #2 cylinder (from which the TCI gets its signal) has stopped getting an ignition signal from/to the TCI.

-

I agree that fuel delivery seems to be the issue, although I doubt it is the fuel pump. Of course it could be a bad pump, but First Gen fuel pumps rarely fail. Several things could inhibit fuel delivery: Crimped or partially plugged fuel supply lines. Plugged fuel filter. Faulty fuel pump. Unvented fuel tank. This last issue may be caused by a stuck closed "roll over valve". The roll over valve is a check valve in line with the fuel tank vent. Its purpose is to prevent fuel spillage out the tank vent in the event of a tip over. The check valve has been known to fail in the closed position. If closed, the tank will not vent. If the tank is not vented to atmosphere, a vacuum will form within the tank as the fuel is consumed. Fuel will not then flow unimpeded to the fuel pump or carburetors. If the problem is an unvented tank, a quick way to test for this condition is to remove the fuel filler cap. If a swoosh sound is exhibited (as if air was quickly filling the fuel tank), then the failure of the tank vent is indicated.

-

A Bucket List Trip. Or how I will spend my summer.....

Prairiehammer replied to The Tooch's topic in Watering Hole

You guys are definitely having issues with geography. From the Day 2 blog entry: "This was taken after crossing the Mississippi River from Indiana into Iowa.":think: From the Day 3 blog entry: "Anyways, on to today. We started out in Keokuk, IL.":doh: As for seeing my tractor; we farm an extensive area, but nowhere near US 136. Keep the rubber down Dave. Have fun! -

From Dunlop: Thank you very much for recent inquiry on Dunlop Tires. Tube type tires require a tube to maintain the proper air pressure as tube type tires are not built the same as tubeless type tires. A tubeless tire has an "inner liner" on the inside of the tire carcass that is designed to be airtight. The tube type tire does not have this same inner liner and if run without a tube will lose air over time. In most all cases tube type tires are designed for spoked rims that would lose air pressure through the spoke nipples. I would recommend ignoring what your friends are telling you on this matter and install a tube in your tube tire tires. Thanks again for your interest. Brent Durfee Regional Sales Manager Dunlop Tires Phone & Fax 714-572-8485

-

CLASS pump & manifold

Prairiehammer replied to garyS-NJ's topic in Venture and Venture Royale Tech Talk ('83 - '93)

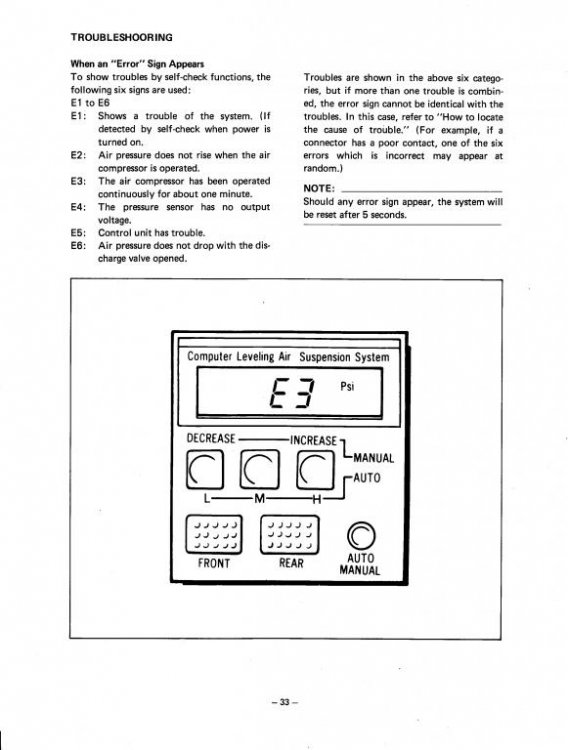

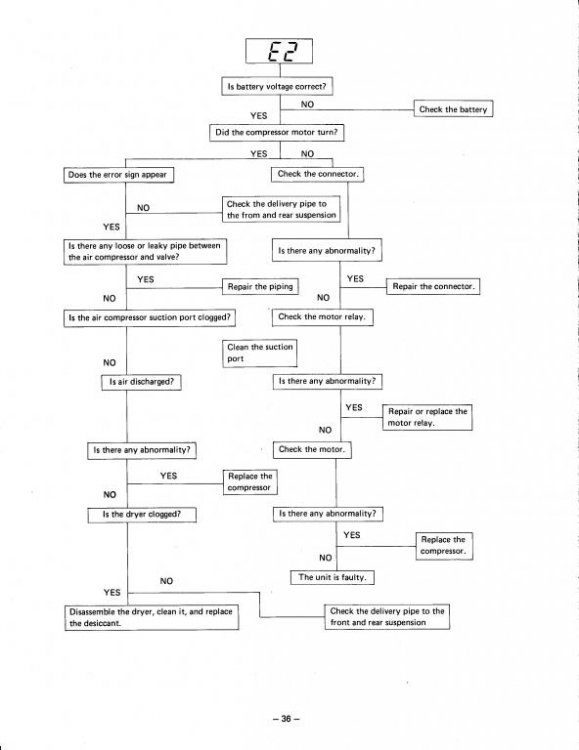

From the Service Manual:| "E2 code: Air pressure does not rise when the air compressor is operated." The causes include worn compressor ring, leaking connections, clogged intake filter, clogged air dryer, unseated solenoid valve(s), reed valve (acts as a one way check valve) defective or dirty. -

CLASS pump & manifold

Prairiehammer replied to garyS-NJ's topic in Venture and Venture Royale Tech Talk ('83 - '93)

There have been some instances where the desicant has broken down into fine, dust like particles. This dust has been known to migrate to the solenoids, causing sluggish solenoid operation as well as poor sealing in the solenoid valve seat. Silica gel debris may also get into the "reed valve" (a one way check valve of sorts). If the reed valve leaks back, the compressor may be working too long without sufficient pressure build-up, causing the E2 error. -

Here is a thread with missing pictures: http://www.venturerider.org/forum/showthread.php?48559-Brake-hose-description-list&p=472651#post472651

-

Your project is not for the faint of heart or for one who is not familiar with the intricacies of the Venture electrical system. But, since it has been started already, there is no looking back, I guess. The electrical system of the First Gen Venture is fairly complex, what with the safety interlocks, audio, CLASS and ordinary lighting. First thing I would do is to become a Supporting Member, so as to insure that your source of expert advice does not go away part way through your project. You are going to have a lot of questions about "what does this wire do?", "How come it won't start/run after I clipped this wire?", etc. There are some electrical differences between nearly all the years of the First Gen Ventures. So the Second thing I would do is to identify the year and model of the Venture that you have. Look beneath the brake pedal on the frame rail and note the white label denoting the manufactured date and the VIN. Then tell us what the information is. Zagger has done what you are planning, so he may be your primary "go to guy", but the rest of us will be able to help with the details. Freebird's referral to the wiring diagrams (by member Dingy) is the best starting point. Download, print in large format and go for it!

-

I think you should name your new Venture after your Love AND what you do with her (the bike. I don't wanna know what you do with Eileen), so...ILean. Well, shoot! Someone beat me to the punch!

Rinaldi.jpg.7345ed97b0bed28c13512bdba76f5464.jpg)