-

Posts

3,621 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Store

Everything posted by Prairiehammer

-

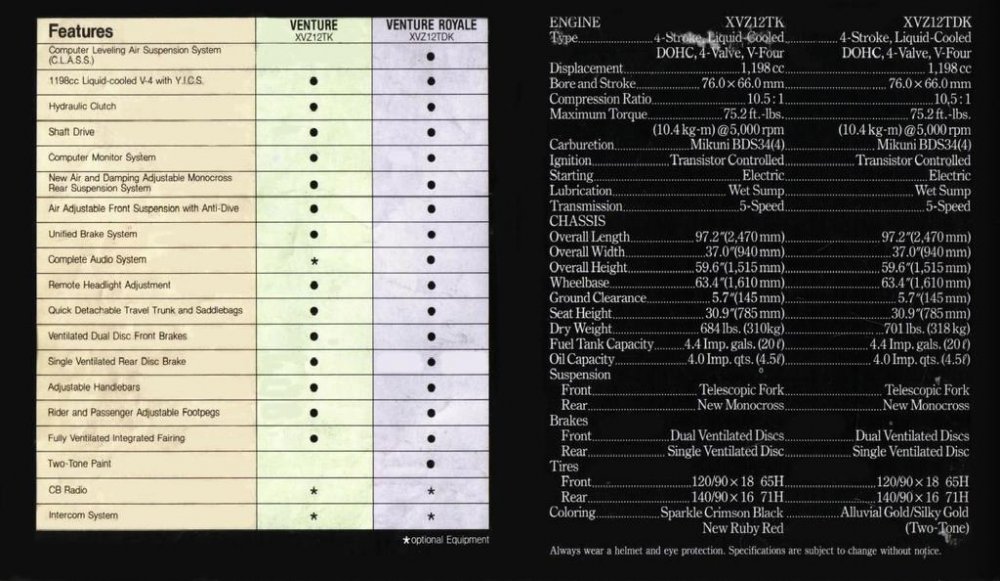

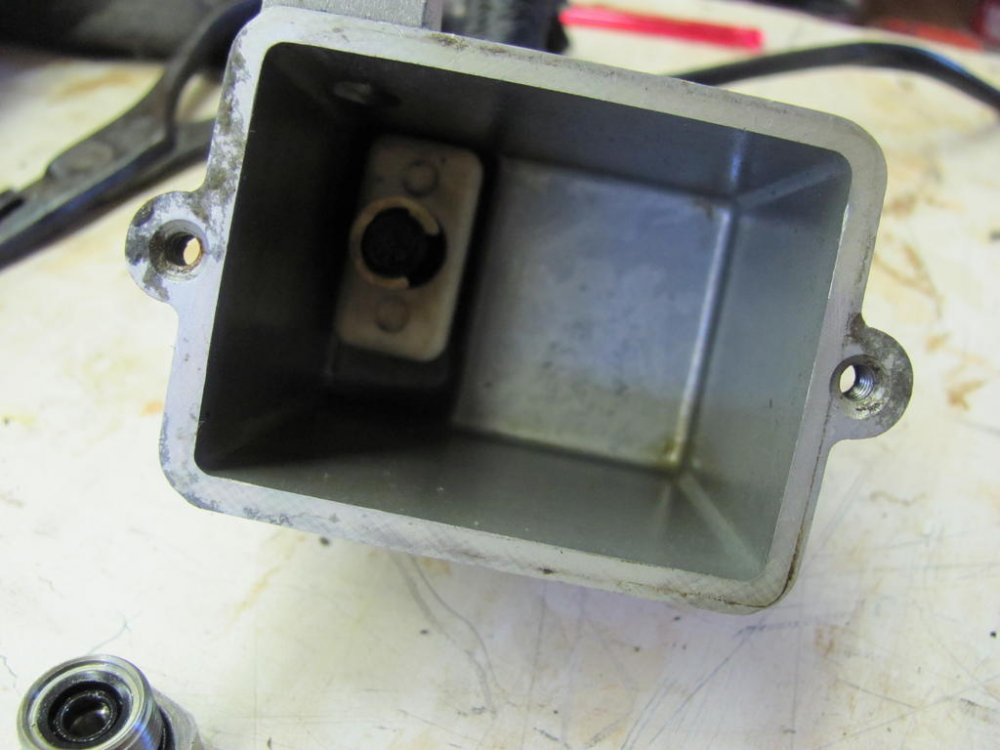

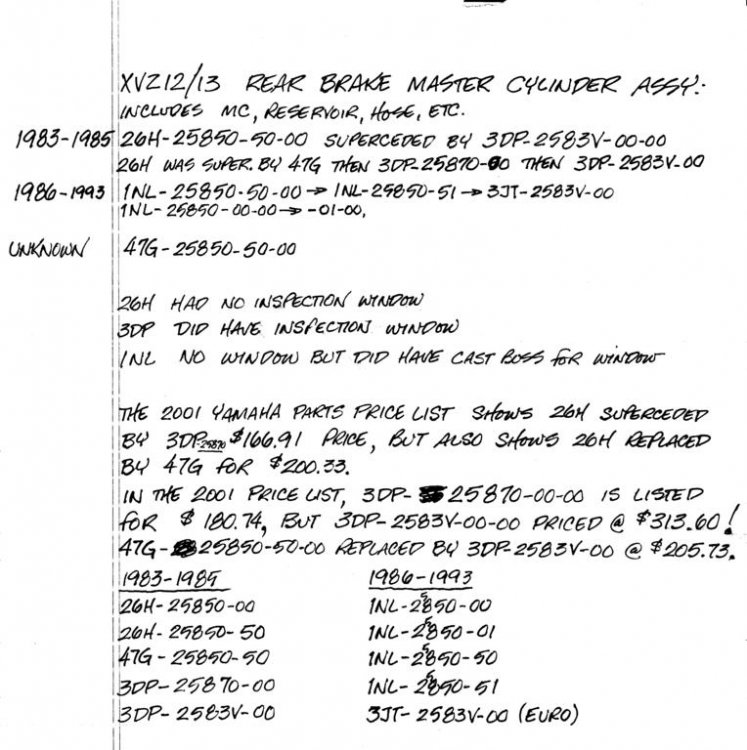

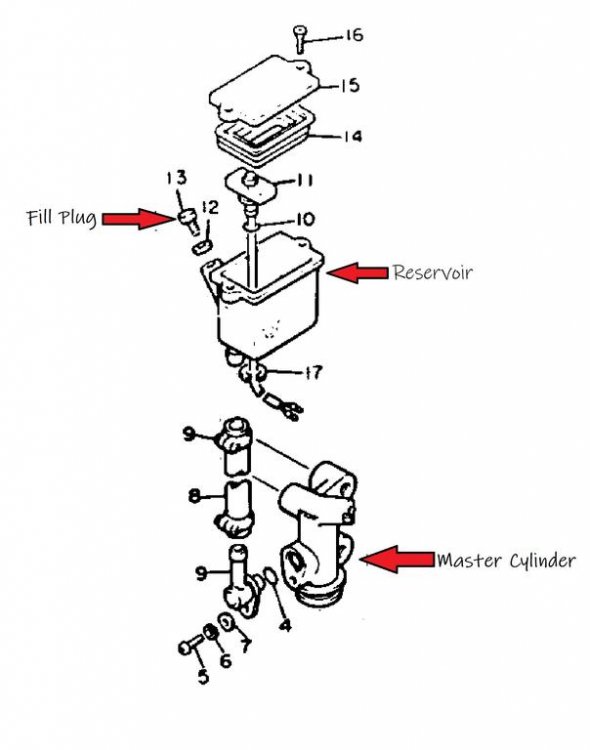

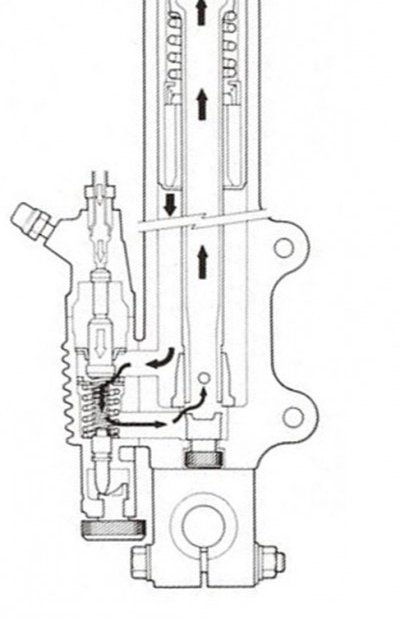

Indeed, the fill plug boss is what breaks off when too much torque is applied to the seized fill plug. It happened to me on my 1983. Using an open end wrench of the correct size or an adjustable wrench, on the flat sides of the projecting fill plug boss and applying equal counter force to the torque generated while attempting to remove the plug will prevent the boss from breaking off. An example of the broken reservoir (from my '83) here: Yes, the pictured master cylinder assembly with the sight glass on the reservoir is for a MKI. Some 1983 reservoirs had a ring cast into the reservoir but no sight glass. Even earlier 1983 versions were completely devoid of the sight glass ring casting (as in my 1983 reservoir pictured above). But, my 1990 had a reservoir with the cast in ring for the sight glass and even the "LOWER" line. I have also a picture of a European (3JT) 1990 with the sight glass. Bottom line, any of the reservoirs will work on any of the years. I have previously done extensive research on the rear brake master cylinder assembly. Here are my notes on the subject. Keep in mind the various part numbers are for the COMPLETE rear master cylinder assembly, which includes the reservoir. Different part numbers do not necessarily reflect differences in the reservoir alone. Yamaha never assigned a part number to the reservoir only. An empty reservoir may allow the bellows to descend quite aways. Look closely at the picture of my broken 1983 reservoir and you can see the bellows has extended quite low into the reservoir. But, I agree that the bellows would probably not be able to obstruct the float for the fluid level indicator. The float rides up and down on a hollow stem containing a magnetic switch. The top of the stem would likely prevent the bellows from contacting the float. Maybe. A pic of the interior of the rear brake reservoir from my 1990. The rectangular white part is the float.

-

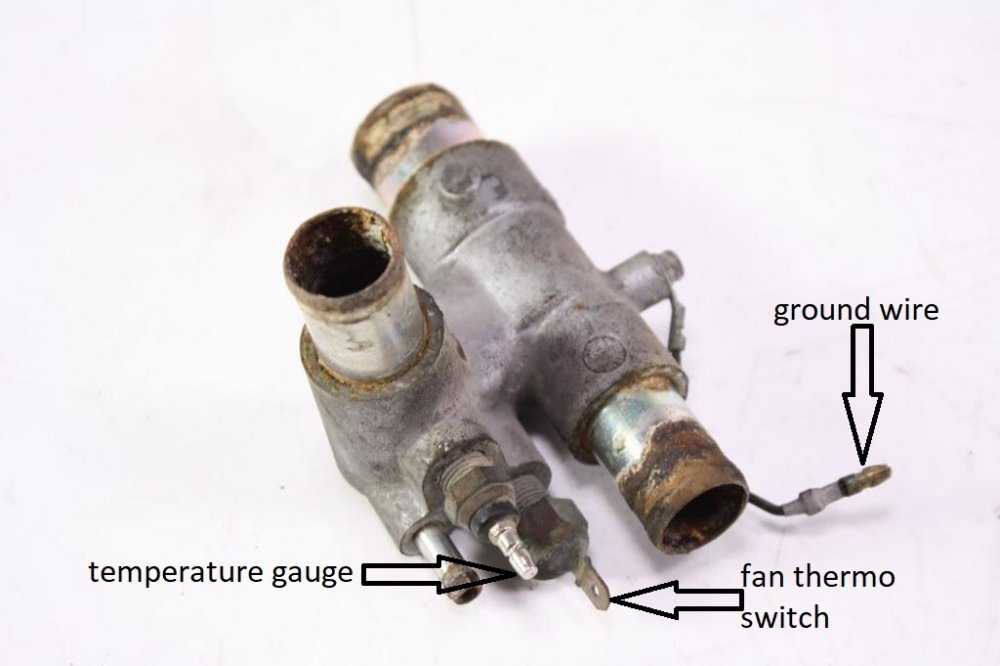

The thermometer wire is green with a red stripe on the 1988 (and others). In addition to cleaning the bullet connector, crimp the female part of the connector slightly to tighten the connection. Clean the male part of the connection as well. Trace the wire to the instrument cluster and insure that the connection at that end is good. Check for continuity from the thermo-unit end of the wire to the instrument cluster end. Check for 12 volts at the thermometer/temperature gauge, the brown wire. Ground the green/red wire with key on. The gauge should go full scale. Check the black ground wire for tightness on the cooling system "joint" where the temperature sending unit is mounted. Clean and tighten the ground lug/screw.

-

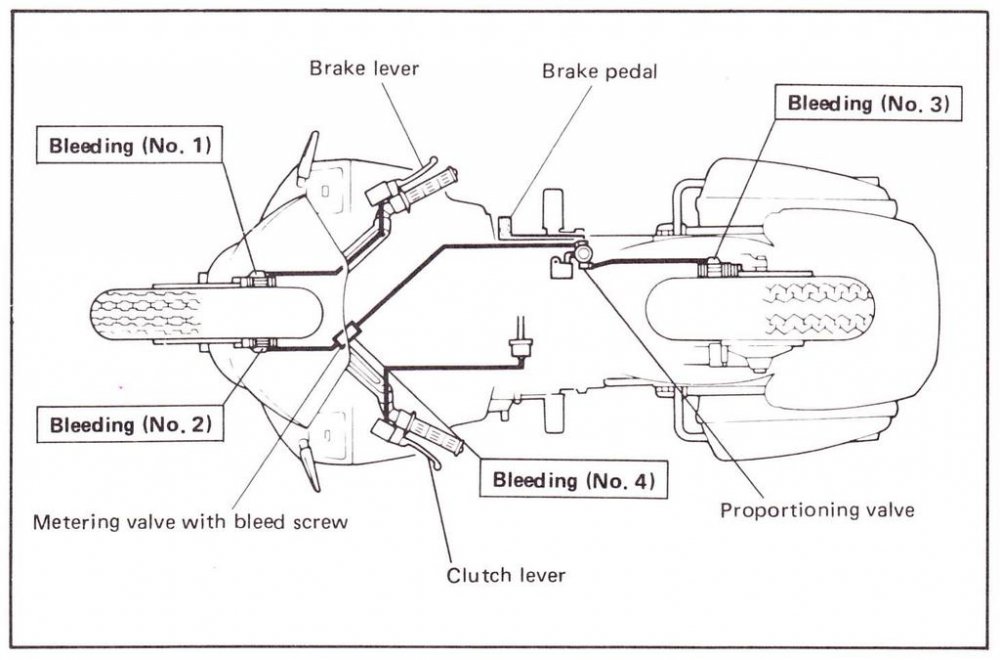

Be very careful while attempting to remove the fill plug. It is often very tight and the boss it screws into WILL break off the reservoir if too much torque is applied to the fill plug. I recommend using two wrenches when removing the fill plug. One wrench is fitted to the boss and the other to the plug. Hold back on the boss while loosening the fill plug. As for the brake system bleeding order, Yamaha says to do it in this order:

-

‘83 venture single carb conversion

Prairiehammer replied to Venturezach's topic in General Tech Talk

The 1983 Venture did not come with cruise control. On the subsequent years of the Venture, the cruise control utilized a vacuum pump, not manifold vacuum. What brand cruise control did you have? The 1983 TCI requires the vacuum source be ABOVE the carburetor butterfly. The TCI will not function correctly if the vacuum source is from the intake boot. -

Teardown and rebuild into something a little more... Me

Prairiehammer replied to Loy's topic in Videos

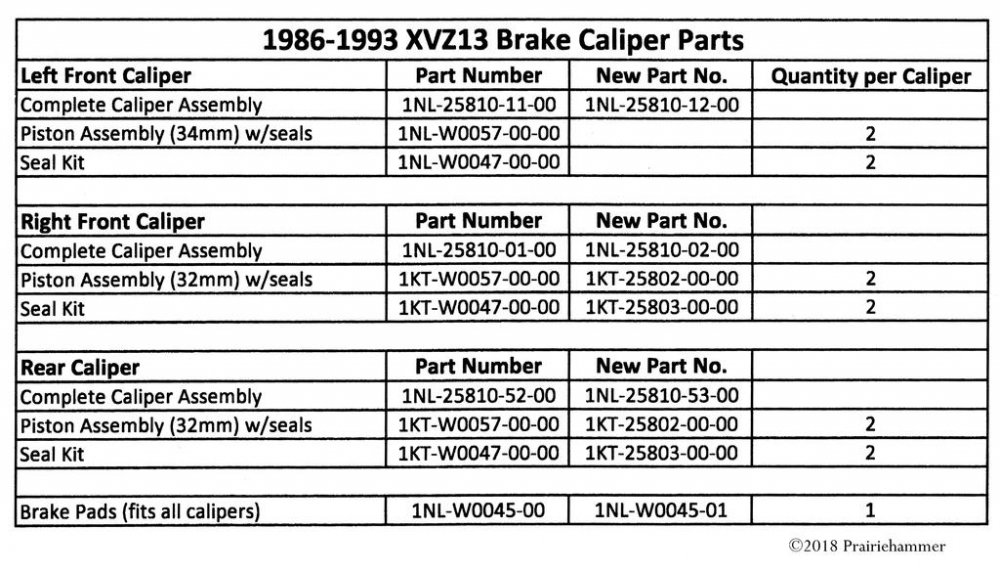

O.M.G. What are you doing to my bike? BTW, the banjo bolt in the rear brake reservoir was just a "plug" that I had on hand. It fit. It kept stuff out of the reservoir. Find an appropriate bolt/plug to replace it. Don't put too long of a bolt in there as a plug. And make sure to use a crush washer as a sealing "gasket". You may find that the stock front master cylinder is inadequate for use with two calipers. You will probably want to get a 1986-1993 (MKII) front master cylinder assembly to use instead of the 1983-1985 (MKI) front master cylinder. The MKI master cylinder has a ½" bore. The MKII master cylinder has a 14mm bore. Most find the ½" bore acting on the now four pistons does not deliver enough force nor does it give a good progressive brake "feel". Did you use a double banjo bolt (two orifices) at the front master cylinder? Also, you should have removed the proportioning valve from the rear master cylinder and attached the rear brake line directly to the rear master cylinder. Or at least gutted the proportioning valve, removing the inner workings. -

Brake Rotor

Prairiehammer replied to dna9656's topic in Venture and Venture Royale Tech Talk ('83 - '93)

When installed on the wheel correctly, the brake rotor rim should be offset toward the swingarm, i.e. dish out. -

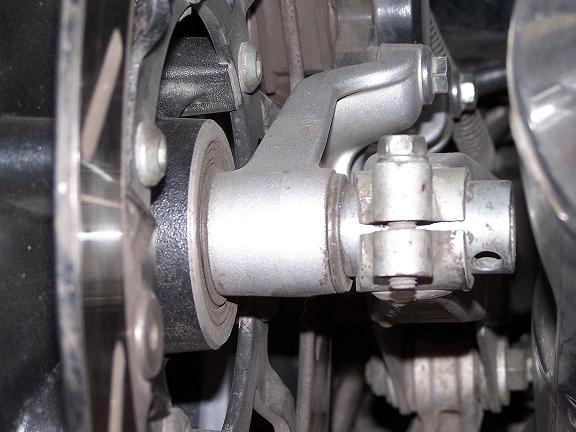

The caliper bracket pivot on the 1983-1985 is a bolt screwed through the swing arm. The caliper bracket pivot on the 1986-1993 is a welded on (to the swingarm) post. Doug, can you slide the bare caliper bracket onto the pivot post, i.e. without the caliper attached? Can you slide the bracket onto the pivot post when the big end of the bracket is not in position on the axle? If the unencumbered bracket slides onto the pivot post easily, but will not when installed on the axle, there is either an alignment problem or an assembly problem or a incorrect part problem. An example: You are not trying to install a 1983-1985 caliper bracket on the 1988 swingarm are you?

-

Only thing I can think of is that the torque for the short bolt is about half that of the longer bolt. Don't strip it out! Frankly, I'm not sure I would mess with it. The minor damage done by the incorrect long bolt will not be fixed by the substitution of the correct shorter bolt. As an aside: the parts diagram is the reason for the (probably) many examples of the long bolt in the wrong location. Notice, even though the part number describes a 16 mm long bolt, the diagram clearly shows the longer (20mm) bolt in that location.

-

An alternative to sourcing U-joint components for the XVZ12/XVZ13 (ALL XVZ as well as most Yamaha shaft drive vehicles): Spider: 2HR-46187-00 Bearing cups: 93399-99926-00 Circlips: 93440-20088-00 This entire assembly is available from several non-Yamaha sources. Usually listed for ATVs. Do a search for 2HR-46187-00. Kimpex part number158267. Sells for $20 or less. For instance: https://www.mfgsupply.com/atv/atvsusp/atvsuspyam/atvsuspyamujoints/19-1003-ref4-atv-rear-drive-shaft-engine-side-u-joint.html http://iowamotorparts.com/yamaha_atv_u-joints.htm https://www.kimpex.com/en-us/products/atv/suspensions-and-parts/universal-joints/kimpex-yamaha-u-joint

-

An alternative to sourcing U-joint components for the XVZ12/XVZ13 (ALL XVZ as well as most Yamaha shaft drive vehicles): Spider: 2HR-46187-00 Bearing cups: 93399-99926-00 Circlips: 93440-20088-00 This entire assembly is available from several non-Yamaha sources. Usually listed for ATVs. Do a search for 2HR-46187-00. Kimpex part number158267. Sells for $20 or less. For instance: https://www.mfgsupply.com/atv/atvsusp/atvsuspyam/atvsuspyamujoints/19-1003-ref4-atv-rear-drive-shaft-engine-side-u-joint.html http://iowamotorparts.com/yamaha_atv_u-joints.htm https://www.kimpex.com/en-us/products/atv/suspensions-and-parts/universal-joints/kimpex-yamaha-u-joint

-

If you retain the stock '83 calipers, there is a 50/50 chance you may not have to change the front brake master cylinder. Some have retained it with no issues. Others have found they didn't like the feel and/or there was too much travel in the lever. Like I say, it is a crap shoot. If you decide to change the master cylinder assembly, go with the MKII master cylinder. It is 14mm bore versus the MKI ½" bore. Your master cylinder reservoir cover will fit identically on the MKII master cylinder reservoir.

-

Consider how I have rigged my 1991. Markland/Drag Specialties/VentureLine driving light brackets with FIAMM car horns (one high pitch, one low pitch). The brackets are mounted in place of the stock horn mounts but include a tab for remounting the horns. I bought the FIAMM horns at an auto parts store. I removed the chrome domed back from the Yamaha horns added the chrome to the back of the FIAMM horns. The FIAMM horns sound just like an old Lincoln or Buick. They draw enough juice though to require a relay. If interested, I have two pairs of the driving light brackets. One pair has Unity halogen sealed beam lights. The other pair of brackets are new in the package, never been mounted. The pic of my maroon 1990 shows how the driving light brackets look. Then the pic of the Unity lights with brackets and stock horns (horns not included). Then the FIAMM horns as mounted on my 1991. Finally a "glamour" shot of me and my 1991.

-

1989 VR finished working on I think it's running good...

Prairiehammer replied to uhfradarwill's topic in Videos

The SAAB was the first (and only) brand new car I have ever owned. Loved it. About ten years after I bought it, the waste gate diaphragm failed at more than 135K miles (the odometer quit maybe 15K miles before). I was unemployed and could not afford to fix the waste gate, so I would just feather the pedal watching the boost gauge to avoid over boosting. Unfortunately, one day as I floored it to overtake a car, I failed to prevent over pressuring and she began to detonate. Immediately started missing. I checked compression and found little compression in one of the cylinders. Never did pull the head to fully assess the damage. Drove it for a few weeks as was, then parked it. Been in a dry shed(s) ever since. -

1989 VR finished working on I think it's running good...

Prairiehammer replied to uhfradarwill's topic in Videos

If you wanna swing by and help me replace a holed piston in my 1978 SAAB 99 Turbo, that would be great!:big-grin-emoticon:It has been sitting since 1988. BTW: Your Venture sounds GREAT! -

1983 Venture, Royal??

Prairiehammer replied to uhfradarwill's topic in Links to Classifieds, Craigslist, Ebay, Sales, Etc.

Like I said, your VIN indicates that it is a 1983 Standard. I agree, like I said, it appears to be the original color for a 1983 Standard with "New Ruby Red" paint. Is there "Royale" badges placed on the sides of the saddlebags or are there "XVZ12" badges on the saddlebags? -

1983 Venture, Royal??

Prairiehammer replied to uhfradarwill's topic in Links to Classifieds, Craigslist, Ebay, Sales, Etc.

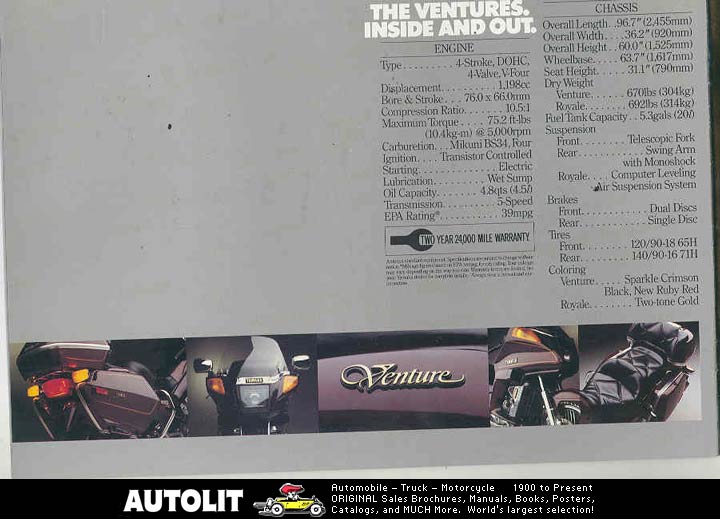

frankd is correct, the 1983 Royale (XVZ12TDK) came only in Alluvial Gold/Silky Gold (his version of "yellow". While your bike has a 1983 instrument panel, the color is not correct for a factory 1983 Royale. Also, the Royale has the CLASS from the factory, while yours shows the Schrader valve in the steering head crown, just as a Standard would have. ALL Venture Royales came with Mitsubishi audio (cassette and AM/FM radio) and CLASS as standard from the factory. The only definitive way to know what your Venture was built as is by the VIN/frame number. Royale badges can be applied to any model, plastic pieces swapped or repainted, etc. *EDIT*: Paul, I just looked at your submission of the VIN for my database and your VIN confirms that you have a 1983 STANDARD (XVZ12TK). Not a Royale. Someone has put the "Royale" badge on your top cover. The badges are just applied with double faced foam tape. Another clue to your bike being a Standard and not a Royale is the single color paint (New Ruby Red). All Royales came with two tone paint. -

1983 Venture, Royal??

Prairiehammer replied to uhfradarwill's topic in Links to Classifieds, Craigslist, Ebay, Sales, Etc.

It is a 1984 Standard. The VIN will be JYA41R00xEA00xxxx. -

I do not. Sealed tapered roller bearings are relatively uncommon and doing a cursory search revealed no sealed bearing equivalent. There may well be one out there. Personally, I see no need for a sealed bearing at the swing arm pivot. The bearing should be packed full of grease and there is a fairly robust cover and a convoluted path for dust and moisture to migrate. Keep in mind that the swing arm has a VERY short travel and and virtually no rotational speed. Unlike a wheel bearing, for instance. Even tapered roller wheel bearings, subjected to much greater load, much higher rotational speed and wetter conditions are not commonly sealed. Pack with grease, assemble and call it good.

.thumb.jpg.15c1add25ab8530d1b45db844a485450.jpg)

.thumb.jpg.9684cf19941c3a71ee9da1e249449b7e.jpg)