-

Posts

5,403 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Store

Everything posted by dingy

-

Attached picture shows what I did to front motor mount. On a 2nd gen, the two plates that I have mounted on the outside of the frame rails at the front mount points are connected by 2 tubes and mounted inside the frame rails. I used long 1st gen bolts that go thru both plates with a tube that bolt passes thru to the 'exact' length between the solid mount bushings. This will allow the bolts to be tightened down without potentially causing the block mount ears to snap off. Picture of unmolested 2nd gen attached. Gary

-

The heads will bolt up to the block OK. After that it's going to get interesting. The exhaust ports on the later Ventures is angled significantly outboard to allow the exhaust pipes to be routed outside the frame rails. VMax & 1st gen Ventures exhaust ports are 'straight' out, allowing the exhaust pipes to be routed inside the frame rails. If the heads are on the block, then a 1st gen intake setup could be mounted. It is right at physically impossible to mount a VBoost unit in a 2nd gen frame. Slim chance it could be done but the carb rack would need to be split in half and brought in from each side and then connected. I have tried doing it. There is not enough clearance to get a full carb rack under the center wishbone rail. Gary

-

faulty pressure sensor

dingy replied to garyS-NJ's topic in Venture and Venture Royale Tech Talk ('83 - '93)

Shotgun is a method of clearing jets and some internal circuits on carbs without dis-assembly. I just did it to Tweety a couple of weeks ago and it cleared up a very annoying backfire on 1 cylinder in 3-4000 rpm range. http://vmax.lvlhead.com/tips/shotgun.htm This air gun from Harbor Freight is also very helpful. http://www.harborfreight.com/pistol-grip-blow-gun-68259.html Link to youtube video showing pea shooter. Gary -

It will be in mail Monday. Priority. Label shows 2 day shipping. Gary

-

Send me your address. I have a good 88 TCI that I will send to you. Gary

-

re-wire emergency flashers to battery

dingy replied to videoarizona's topic in Royal Star Venture Tech Talk ('99 - '13)

At one time I worked with Ponch via phone to get hazards working and we were not successful. Been quite a while, I don't remember specifically what we tried. Gary] -

exhaust collector options

dingy replied to jimmyenglish's topic in Venture and Venture Royale Tech Talk ('83 - '93)

There is nothing on a VMax exhaust that will work on a Venture. Front header pipes are about 3" shorter on a VMax then have have a crossover tube between front headers prior to merge with rear pipes. Rear headers will not fit due to mono shock interferences. Picture attached showing a pair of rear VMax headers on motor that I built for RSV Hybrid setting on bench. The VMax stock configuration is 2 cylinders into 1 collector into one muffler on each side. Diagonal cylinders into each muffler. One of my failures at getting an exhaust on a 1st gen motor in a 2nd gen frame was to try VMax setup, I didn't get to point of buying collector/muffler components because I couldn't get stock rear headers to fit into modified 2nd gen frame. I ended up removing the frame cross brace tube in front of the shock dog bone cross tube and replaced that cross member with a 1/4" plate steel that was formed to allow enough clearance to get a set of very modified rear pipes to mate up with a somewhat modified Marks collector. It ain't pretty, but not visible. And to be fair, this was with a 2nd gen frame, but I have a decent running 1st gen setting here that I am very familiar with, and its going to have similar issues with a VMax exhaust. Frame modification wouldn't need to be done, since a 1st gen uses inside the frame rails exhaust, similar to VMax. but its the rear header crossover that is main issue. Look at 2nd picture, stock VMax rear tubes. This plumbing is vastly different than a Venture, rear tubes for a Venture are shown in last picture. Don't let my failure dampen your trying, many ways to skin a cat. Gary -

After market TCI ?

dingy replied to 6m459's topic in Venture and Venture Royale Tech Talk ('83 - '93)

It can be done, but it requires removal of coil/TCI rack. This project is what led me to use Coil over plug setup. Some PDF drawings of box attached. Gary Bracket Assembly.pdf Bracket Bottom.pdf Bracket top.pdf- 33 replies

-

- aftermarket

- bikes

-

(and 3 more)

Tagged with:

-

After market TCI ?

dingy replied to 6m459's topic in Venture and Venture Royale Tech Talk ('83 - '93)

- 33 replies

-

- aftermarket

- bikes

-

(and 3 more)

Tagged with:

-

After market TCI ?

dingy replied to 6m459's topic in Venture and Venture Royale Tech Talk ('83 - '93)

I have Ignitech TCI's on hand if you want on. PM me. I will put info in classifieds. Gary- 33 replies

-

- aftermarket

- bikes

-

(and 3 more)

Tagged with:

-

Right front side of motor, near the water pump elbow. Connects to the block. Gary

-

Batwing fairing

dingy replied to gsmski3484's topic in Royal Star and Royal Star Tour Deluxe Tech Talk

I have one of these I will sell. I was going to put on Hybrid I am building, but it will not work with what I am doing to front end. Never mounted, just as I received it. $200 plus shipping. Gary -

Sean Morley replied back that it is the 13th tooth from the crimped ball behind gear. His facebook page has a picture on it somewhere. https://www.facebook.com/pages/Morleys-Muscle/282702488678 Gary

-

I do have an extra crank. Few pictures attached. It is not a punch mark, it is a circle etched into crank about 1/8" in dia. Extremely hard to see. It is between 2 marks in closeup and just to right of marked tooth. Other 2 pictures are so you can see orientation of crank in regard to mark. Gary

-

I will try to get a picture of a balancer with a visible mark on it from a VMax friend, he should have several. He has forgotten more about these bikes than I know. I don't have an extra balancer shaft. VMax's are identical to the Ventures. Gary

-

There will be no noticeable differences between an RSV & 1st gen motor relative to crank/counter balance orientation. The picture attached will show relative position of crank to balancer. Note the far rod throw on crank is at top position. Look at far balencer offset positioning. Based on these two points it should be possible to locate balancer relative to crank within a tooth or two. This will then narrow down area to look for the balancer mark. You are looking for a mark that is in the 'valley', between 2 teeth, as shown by red mark in closeup of balance shaft. I have had great difficultly as well locating marks on them. Your other option is to go to a dealer and ask them. Gary

-

I don't know of anyone that has used the TCI to drive the tach, but it should be fairly easy to hook it into TCI. On the Bike tab in the Ignitech program that is on the CD, there is a setting to tell TCI how many pulses per revolution the TCI will receive, which should be set at 2, it is set to this in all TCI's I have sold. There is also a correction % setting for some reason. All that would be needed is to run a direct wire to the tach input and hook it to the number 15 terminal on the large 20 pin connector on the TCI, it will be empty as you received it. Reason this needs to be a separate wire is the fuel pump relay also is connected to the gray wire at some point in the circuit. If bike is starting & running, this connection is signaling the pump to operate. By tying to the existing grey wire in the harness with the Ignitech TCI, it will create an issue, don't know what the end result would be, but probably not good. If you do encounter a fuel pump issue, the Ignitech TCI also has an output that can be used to drive the pump, pin 3 on 20 pin connector to TCI. It will take a setting change in TCI programming to enable this, but not hard to do since you have the USB/COM cable. I can send you a couple of wires that have a terminal already connected to one end that fit the TCI main plug harness. You should have some extra loose terminals that I include with TCI's if you have correct crimping tool.This can be a fairly small gauge wire as there is little current involved with either the tach or fuel pump relay circuits, 20 gauge would be fine. A large gauge wire is difficult to crimp on these small terminals. Gary

-

Anti dive bypass plates

dingy replied to Great White's topic in Venture and Venture Royale Tech Talk ('83 - '93)

I just ordered a set for Tweety. I have a set of adjustable bypass plates I made this winter that are rough looking, these are a lot better appearance. Gary -

Freebird's MD, Quaker Steak & Lube Friday night dinner.

dingy replied to dingy's topic in Watering Hole

I have talked to manager at Quaker Steak this weekend and they are expecting group to be there around 5:00 Friday, on the dock. Gary -

Run for it, it's the COPs!

dingy replied to flyday58's topic in Venture and Venture Royale Tech Talk ('83 - '93)

That's an aftermarket cover. One on both sides. MarCarl had made some up a couple of years ago. Gary -

Run for it, it's the COPs!

dingy replied to flyday58's topic in Venture and Venture Royale Tech Talk ('83 - '93)

In some of my previous posts in this thread, I referred to possible failures of 83-85 TCI's without resistors installed in coil circuits. The TCI's that are a concern are actually 83-89 years. In 1990-1993, the digital TCI was used in the Ventures. I have edited those posts to reflect correct information. Gary -

Run for it, it's the COPs!

dingy replied to flyday58's topic in Venture and Venture Royale Tech Talk ('83 - '93)

That opinion is what is prevalent on the VMax site. It is not a sure thing that the 83-89 TCI will fail without resistors, there are some that have said they have not had a problem. My concern with the resistors is that it seems some that are using them state that the gap plugs in .026" range. This then IMO degrades the intensity of the spark. They probably are narrowing gap in order to get plug to spark with reduced current in coils. Within the last month I have worked with a user of the Ignitech TCI and recommended he change a setting in TCI to compensate for the lower coil ohms. He had been running resistors in the coils due to a carryover from his stock TCI. He did this and then gapped plugs to .032 and said bike is starting much better. than it was with narrower gap. I have not heard of anyone using COP's on a 2nd gen. Probably has been done though. I am sure that they will fit in heads with chrome covers on, see prior picture of Sylvester in post #9 of this thread. Heads on motor are VMax with chrome RSV covers installed. There is a set of RSV valve covers on heads that allow use of chrome covers, so I am sure geometry is same between 1st gen & RSV heads. Gary -

Run for it, it's the COPs!

dingy replied to flyday58's topic in Venture and Venture Royale Tech Talk ('83 - '93)

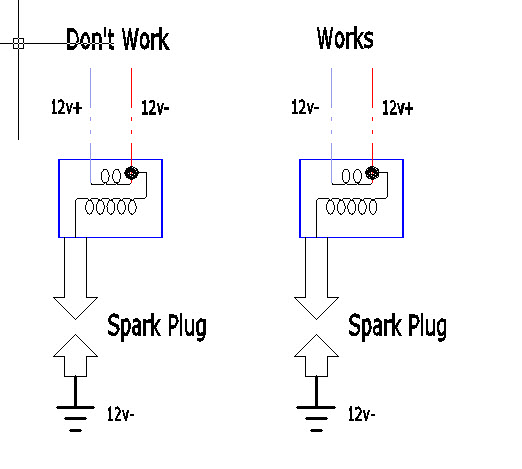

I have been running COP's on Tweety for 2 or 3 years now. On the 83-89 MKI's there needs to be a resistor installed in the circuit feeding the coils. Reason behind this is that stock coils are in the 2.4~3.0 ohm range on the primary side. Cop's are under 2 ohms in general. This lower resistance allows more current flow through the primary circuit, which has been known to burn up stock TCI's in some cases. The 90-93 MKII's have a better digital TCI and thus much better at handling the increased load. The Ignitech aftermarket TCI has a setting in it which compensates for the different coil resistance. The VMax member that is the resident guru on he COP's system won't disclose the exact ohm & wattage of the resistor that he uses. I know it is a ceramic unit that will dissipate the heat it generates. Ohms would be near 1 ohm, but wattage he uses I don't know. He sells kits for installation on the VMax's and would probably supply sets for Ventures. Lead length is different as VMax's have rear coils mounted in back. Very good & honest person to deal with. I do not know pricing of kits. COP's in general are a fairly easy install. The coil is about 1" in diameter and about 6" long. Length of coil is important as there are clearance issues with some of the longer variants. Correct polarity connections to the coils is critical. Both sets I use have come from Honda CBR's, 2006 & 2007 years. They are Denso coils. Pictures attached. When buying the coils, it is important to also get the sub harness that has the special connectors that mate to the coils. Connection to wire harness is made at the yellow connector for each coil. Both sets I have bought on Ebay, with harness have been less than $50. Stock coils can remain in place on bike. Rack coils are mounted to also holds TCI & vacuum sensor so it must remain if using stock TCI in original location. One drawback to COP's that would be of little significance to Venture owners, but annoys the VMax guys is that a traditional timing light doesn't work with them. This is significant when dyno testing as RPM indication is typically taken with a clamp sensor around the spark plug wire. There are options though to circumvent this issue. I don't have a CB or intercom system on Tweety, so I do not have any input on interference differences when using COP's. I have been very satisfied with COP's on Tweety, which has Ignitech TCI. I am using NGK Iridium plugs gapped at .032". The Hybrid (Sylvester) also has COP's but has not been started yet. Will be near identical setup to Tweety, so there should not be any difference. Last 2 pictures are of COP's on Sylvester's 1st gen motor in a 2nd gen frame. Gary -

#4 cylinder is within spec, but it is possibly due to carbon build up on the piston that is getting it that high. 170~180 is more in the normal range that I have seen. The 1300 that is in my 83 has VMax heads on it and block has been milled .040". It was in the 200 range when motor was rebuilt. I would imagine it would test around 190 now after 3 years on it. Other three cylinders have one or more of several possible issues. Again, carbon build up may be keeping valves from fully seating, worn or froze rings, out of spec valve clearance, or worn pistons (rare on these motors), Abrasions on cylinder walls. Did you put oil in cylinders to see if that changed compression readings? SM says a few drops, that to me is way to little to make any difference. More like a teaspoon. Intent is to coat cylinder walls to see if rings are culprit, couple of drops won't do that. Did you have throttle wide open. Was motor warm? Thread below would be nice for you to do if you want technical information on your bike. The 1200 & 1300 motors are very similar but have some differences along the lines of your inquiries. http://www.venturerider.org/forum/showthread.php?90684-Help-us-to-Help-you-with-your-bike-info-in-your-header-updated-to-new-forum Gary