-

Posts

5,403 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Store

Everything posted by dingy

-

There are numbers engraved on the lower crankcase, 2 digits over 4 digits on one side and 2 on other. Left side lower 4 digits are crank main bearing size, upper 2 digits are balencer shaft sizes. Don't know what right side numbers are for. On the crank, there is a 4 digit number stamped on it and a 2 digit number, and a 2 digit number on the balancer shaft. Each rod will have a number on it, usually ink stamped on, not stamped or engraved, I think each starts with an 'E', but not always. Letter doesn't matter, only number. The case & rod numbers are 8 to 5 range, the balance & crank shaft are 0 to 4 range. subtract the shaft numbers from the case numbers to get the bearing sizes. See attached PDF cut from service manual, and a picture of bearing markings on case. Most bearings are in mid range, #'s 4 & 5. That is design tolerance factory tried to hit. Plastigage is a real chore on the block, Block halves need to be reassembled with sealer, then split to read plastigage. You need a known size bearing in place, so you know which way to go if reading is incorrect. Then do it again. Rod bearings, are much easier to plastigage. Almost all motors I have torn down have had color markings unreadable on bearing s. There is a thin strip on edge, in middle of arc on one side of bearing. The videos that are available for $20 for VMax motor, go into bearing selection in depth. Gary 82448.pdf [ATTACH=CONFIG]105715[/ATTACH] [ATTACH=CONFIG]105716[/ATTACH]

-

COP (coil over plug) ignition

dingy replied to Rosie1965's topic in Venture and Venture Royale Tech Talk ('83 - '93)

The COP's connect to the 2 pin connector on the main harness at each coil. Cop's do not make a connection directly to TCI. There are 4 yellow plugs (2) pin plugs, 1 to each coil, stock coil has mating plug. Unplug stock coils and wire COPs into the harness end of each plug. Gary -

COP (coil over plug) ignition

dingy replied to Rosie1965's topic in Venture and Venture Royale Tech Talk ('83 - '93)

It's about 30 min or less to install ignitech TCI. Then remove stock plug wires to coils. Install cop sticks and wire power leads into connectors where existing coils plug into main harness. Probably a couple hours installing COP's. Ignitech TCI does not connect directly to coils, it interfaces through existing main harness via a short adapter cable. Changing to COP's from stock coils is seperate change from Ignitech swap. Benefit I see with Ignitech, there is no need for resistors being installed in COP's. Ignitech has a setting that is changed when using lower primary resistance coils. Gary -

Attention Whore !! Gary

-

You might run into an issue on the inner bore of the tube. This is a rather close machined surface for the slide bearings. The chrome thickness might make the bore a little tight. Gary

-

If you have tail lights, then it possibly is the high/low switch that is issue. If you don't have tail lights then it is the feed circuit through the head light fuse. Simplified wiring diagram attached, head lights are on middle left side, dimmer switch to left of head light, fuse down & to right. This schematic doesn't show all the connectors, full schematic is at link below. http://www.venturerider.org/forum/showthread.php?t=42357 Gary

-

The groove around the locking nut seen in post #107 in this thread is a way to know that it is a left handed fastener. Now see this is a duplicate of a couple of posts prior, hate it when I do a 'Me Too' post!! Gary

-

COP (coil over plug) ignition

dingy replied to Rosie1965's topic in Venture and Venture Royale Tech Talk ('83 - '93)

I don't know of a reason they won't work on an RSV. I have test fitted them on the motor I have built for the RSV Hybrid and they will clear the chrome valve cover caps on the valve covers. This was with the sticks from a 2007 CBR. Gary -

COP (coil over plug) ignition

dingy replied to Rosie1965's topic in Venture and Venture Royale Tech Talk ('83 - '93)

Below are a few more links to VMax site dealing with COP's & resistors. VMax site is not PG rated, FYI. http://www.vmaxforum.net/showthread.php?t=31975&highlight=cop%27s+resistor http://www.vmaxforum.net/showthread.php?t=5427&page=5 http://www.vmaxforum.net/showthread.php?t=29827&highlight=cop%27s+resistor http://www.vmaxforum.net/showthread.php?t=28460&highlight=cop%27s+resistor http://www.vmaxforum.net/showthread.php?t=16764&highlight=cop%27s+resistor Gary -

COP (coil over plug) ignition

dingy replied to Rosie1965's topic in Venture and Venture Royale Tech Talk ('83 - '93)

I didn't say every TCI was burnt up using COP's, the digital style stock TCI's from 90-07 on the VMax's seem to hold up better than the analog TCI's on the 85-89 VMax's. Gary -

COP (coil over plug) ignition

dingy replied to Rosie1965's topic in Venture and Venture Royale Tech Talk ('83 - '93)

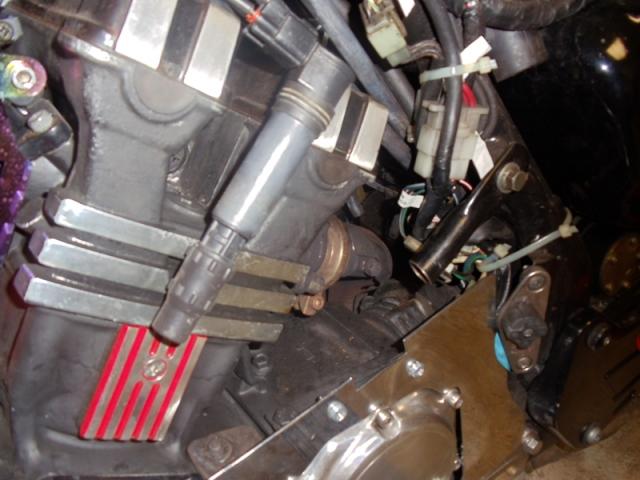

Attached is a picture of kit VMax member sells. His screen name is 88vmx12 VMaxforum.net Price he has on this kit is $215, it would be a little less for a Venture, there is no use for the T-boost adapter shown in upper left corner on a Venture. http://www.vmaxforum.net/showthread.php?t=24692 Gary -

COP (coil over plug) ignition

dingy replied to Rosie1965's topic in Venture and Venture Royale Tech Talk ('83 - '93)

The COP's (Coil Over Plugs) coil sticks are fairly easy to install, with some rewiring to the stock harness. Main issue with using them is the primary coil in the COP's is a lower resistance in some COP's than what the primary coil resistance is in the stock coils. This lower primary resistance then leads to a higher current draw through the coils, which has been known to damage the internal circuitry on the stock TCI's rendering them useless. There are some COP's made that have a primary resistance in the 3 ohm range of the stock coils, but I don't know offhand what models they are. I have gotten both sets of COP's I use from Ebay. Both sets was from a 2007 CBR, You want to get a set that has the wiring connectors included as they are rather specialized connectors. One set I paid $20 for and other was $45. One of the VMax guys has (or had) a kit he sells with a rather large resistor in each of the coil circuits to prevent the over current. He sells the complete kit, Good (used) COP's, and wiring harness with resistors. I do not know price, but I could find out. He hasn't divulged the type of resistors he uses that I know of. There are also COP's coils available in different lengths, the longer ones probably won't fit on a Venture. Since you are happy with your current TCI, next bit is info only. The Ignitech TCI's have a dwell setting in the program that will compensate for the lower primary coil resistance. I have had COP's on Tweety (83 VMaxed 1300) for 2 years and it works well. I initially started using COP's due to wanting the larger VMax air box, which interfered with battery location on the Venture. Be eliminating the stock coils, I was able to relocate the battery into the area where they were. Gary -

http://www.fool.com/investing/general/2014/02/17/is-harley-davidson-the-worst-motorcycle-money-can.aspx Gary

-

How did you fix this with a piece of 'seizing wire'? The brake switch is designed to allow the switch to be adjusted in its holder with the plastic nut that is noted by green arrow in 1st picture. This nut is adjusted so as to move the switch up or down in the holder, position is determined by slightly depressing brake pedal and seeing if brake light turns on. I like it to turn on when the pedal is slightly depressed, but not so much that I am engaging brake pads. This is so as soon as I tap the brake light comes on. The above being how 'I' like it, this is where the spring part of the design comes into the picture. As the brake pedal is further depressed, at some point, the plunger inside the switch is going to reach its maximum travel without damage to the switch. The spring is then stretched to accommodate the remainder of the brake pedal travel to engage the pads & rotor. This amount of full travel by the brake pedal will increase as pads wear. It is adjustable by the mechanism between the pedal & master cylinder plunger arm. The 2nd picture shows a common spring that is probably available at hardware & home improvement stores. Spring needs to be fairly stiff to pull plunger in switch to its closed position, as there is an internal spring inside switch that returns plunger to its open position. (3rd picture). The one shown in 3rd picture is probably to light weight to correctly work, just showed it as an example. Gary

-

Below is a link to cleaning rear brake switch. The rear switch starts on page 10 of the PDF, it is different from the front brake/clutch switch. http://www.venturerider.org/forum/showthread.php?t=42720 Gary

-

Does the Dyna unit allow the motor check light system to function? If it does not, then the Ignitech would be an equal, if not more versatile unit to consider. I know the motor check light will not function with an Ignitech though. The Ignitech has far more programmable settings and other features than what I have seen from Dyna units. For one, RPM settings can be set at any point in 100 RPM increments, this is completely independent of the timing curve put into the module. I have a few adapter cables for the 2nd gens, just haven't had a good chance to try one out. Gary

-

Upcoming water pump fix project ????

dingy replied to Peder_y2k's topic in Venture and Venture Royale Tech Talk ('83 - '93)

Informaion below is for rebuilding waterpump on VMax's. Parts are same as Ventures. SEAL, MECHANICAL 11H-12438-10-00 OIL SEAL,S-TYPE 93101-10090-00 BEARING 93306-00004-00 GASKET,WATER PUMP 3JP-12449-02-00 O-RING 93211-16591-00 (on main outer cover) O-RING 93210-27778-00 (on elbow) Info from Sean Morley at http://www.morleysmuscle.com/ Gary -

Upcoming water pump fix project ????

dingy replied to Peder_y2k's topic in Venture and Venture Royale Tech Talk ('83 - '93)

11H-12438-10-00 is a replacement for 11H-12438-00-00 per http://www.yamahapartsmonster.com/oemparts/a/yam/50042d2ef8700209bc789efc/water-pump item #8. $22.27 before shipping. Gary -

My X Army Son doing a College Survey...Need your Assistance...

dingy replied to GolfVenture's topic in Watering Hole

Been there, done that. Gary -

I just called Oberlin Inn and got a room for June 6th & 7th. She said there are still some rooms available. Mention VentureRider group. Gary

-

No !! I'm shocked that she didn't though...seems like a really likeable old girl. http://i890.photobucket.com/albums/ac103/banditrw_album/funny-gif-cat-shocked-face.gif Gary

-

It somewhat concerns me you are a quality control team member for drones that may be flying overhead and you count 24 days between Jan 21 and today (Feb 8). Seems a little closer to 18 days. You are not a spring chicken, so this can't be 'new math'. Gary

-

It's the next level above sneaking up on a bull in a corral and slappin' it on the ass, and running to get out before it gets turned around and gets you !!! Gary

-

Cancelled Gary

-

Might say '2 birds with one stone' Gary