-

Posts

3,442 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Store

Everything posted by MiCarl

-

That's insane. I understand discontinuing the sitebuilder tools, but I cannot fathom deleting the files. I hadn't heard of 1 & 1. A quick look at their offerings looks like they're selling shared hosting. Shared hosting is inexpensive but performance can be poor if they overload the server your sites are on. You might have a look at webhostingtalk.com. There you can see what other hosting users think of the various providers.

-

If they didn't mention collaboration or synergy they weren't serious.

-

The fan switch is just on/off. It should read open cold and closed hot. As a practical matter the fan shouldn't run much in normal operation. So long as you've got enough speed to ride comfortably there is enough natural airflow that it shouldn't kick on. With the standard temperature switch it doesn't kick on until the gauge reads almost into the red.

-

Gas Mileage Question

MiCarl replied to Chaharly's topic in Venture and Venture Royale Tech Talk ('83 - '93)

The nylon spacer under the needle clip needs to be thinner. Skydoc sells a kit. -

Classic symptoms of plugged pilot jets. You say you took the carbs apart, did you clean the jets?

-

Sometimes they are tough. I assume you have the notch in the bucket oriented so you can get under it?????? On the 2nd gen I just did a couple were hanging into their buckets so tight I could not get my usual pick under them. I used a thin pick (almost like a needle) to push under the shim and create a gap the larger pick would grab so I could pry them out. You do not want to pull the cam. And no, there is not enough slack in the chain. Pulling the cam will make a lot more work and the shim will still need to be pried from the bucket.

-

An update: Furnace crapped out again a few days after the new transformer went in. Manually lit it one time and it was fine for a week. Crapped out again last night and even after manual lighting several cycles it didn't resume firing the igniter. I jury rigged it so the pilot stayed lit to get us through the night. This morning I put the replacement control on. Same thing, control complains of low voltage. This happens even with the gas valves disconnected. Conclusion: ICM Controls are junk. I reconnected the original Johnson Controls G60RBG-3 and it didn't work, but with a different problem. Igniter was firing but the gas valves were chattering. Wiggling the wires I found the immediate problem. After re-connecting that wire the furnace worked normally again. I noticed that the terminals on the old control are apparently steel and have some corrosion on them. I'm wondering if this is the source of my problem. Remember, after I'd disconnected everything to try the replacement control then switched back it worked for almost a year. I'm wondering if all the connect/disconnect cleaned them up enough to get me by until they corroded again. I think the next warm, dry day I'll pull the control out and give all the terminals a good cleaning.

-

With side draft carburetors it is. On down draft it has its own well. On the 1st gen they are removable, but they're unusual in that respect.

-

-

I just had a look at the one on my lift. I can see where the plugs (buttons really) contact the covers. I'm still convinced their purpose is to support the cover. I seriously doubt missing one would cause any problems with oil flow - the oil comes to the camshaft from the bottom and the little that leaked out there really shouldn't do any harm. You can look through the open hole for any signs of galling on the bearing and that should help you sleep better..... That plug is pretty good sized. Probably best to make sure it isn't in the oil pan. Like I said, I'd drain the oil first and see if it flushed out or ended up stuck in the drain hole where it could be dug out.

-

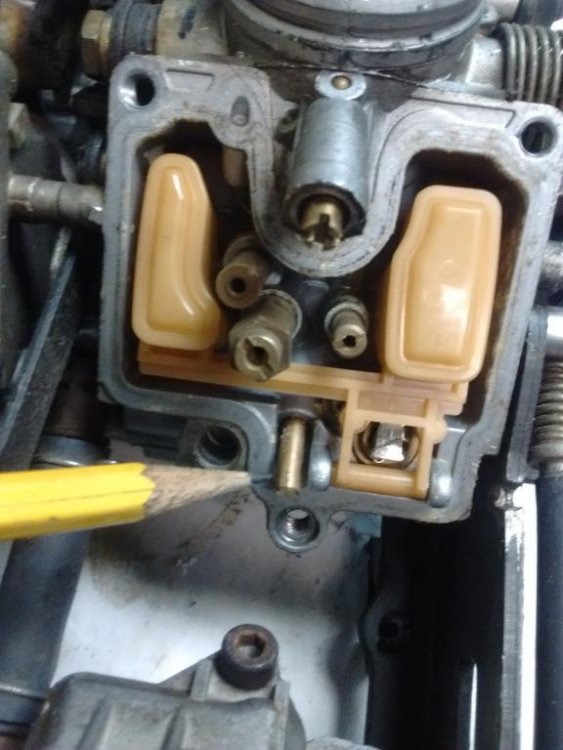

Ok, I just had a look at the carbs on my bench. The needle jet is not in your pictures. The jet itself is ahead of the float pivot. I took a picture that I'll post when I get home later. The emulsion tube is center left in your first picture, main jet holder screws around it. The holes in there are what need to be clean. Have to clean them in place - it's pressed in. If you spray carburetor cleaner in through the air jet it'll come out the holes in that tube - then follow with compressed air. That's all you need.

-

Damn! Wrong again. Most likely it'd end up either laying somewhere in the bottom like yours or get caught by the oil pickup screen. Not sure how much stuff you can collect on the oil pickup without reducing the oil flow.

-

I doubt it's for oil pressure. If it needed to hold oil pressure it would be threaded and have a sealing washer on it. Besides, why put the hole in the cap to just turn around and plug it? I suspect the hole is made for the plug - not vice-versa. I wouldn't be surprised if it's job is to damp vibration by resting against the cover. Frankly, I've never noticed them. Fortunately I've got a 2nd gen on my lift with the covers off for valve lash. I've got to go into the shop tomorrow - I'll give them a close look.

-

It's not stuck to the cover is it? You could try draining the oil and see if it comes out or at least gets hung up in the hole. I'm guessing you never saw it. It might have got lost years ago............

-

I'm sorry, you're asking about the needle jet rather than the jet needle. I'm not sure you can. It may be permanently pressed into the body. I've got a set of 2nd gen carbs on my bench at the shop. I'll have a look Monday if you haven't got a satisfactory answer.

-

Needle jet comes out with the slide. Generally when I'm working on a carburetor I tackle it in this order: 1) Idle mixture screw 2) Diaphragm and slide (I generally leave the needle in the slide) 3) Float bowl cover 4) Float, float needle and jets 5) Starter plunger 6) Air cut off valve

-

I own a motorcycle repair business. Let me paint a scenario for you: I hire someone trained at the best auto mechanics schools, all the ASE certifications etc. He puts a tire on a kid's GSX-R, kid leaves the shop and takes off down the freeway doing a wheelie at 180MPH. Kid loses control and wraps himself and the bike around the nearest immovable object. When they pry the bike loose and pick up the pieces of the kid they find the receipt from my shop in his pocket. Mom is distraught, her baby is gone. Her lawyer sues me, sues Suzuki, sues the tire manufacturer and a dozen other folks I can't even imagine. When we get to court it comes out that my mechanic does not have the credentials to work on a motorcycle. Guess who the fall guy will be? I absolutely will not hire a mechanic that does not have the credentials to work on a motorcycle. In Michigan they make it easy for me - it's illegal to work on a motorcycle for pay unless you pass the state test and get the state license. They give me their license and I post it on the wall in the lobby. This is why I suggested he visit some shops to find out what credentials they look for. It won't matter what he knows if he doesn't have the entry pass. It is not generally a lucrative career. There a few that make some decent money but most don't. Last I checked the average was about $17/hour. If you manage to work year round that'll get you about $35K.

-

We all know that the unexpected can happen anytime, usually when you're least prepared. I would never ride no hands for just the reasons StarFan pointed out. Every once in awhile I have someone bring me his bike complaining of head shake. After I test ride with no issues the customer will want to know it I rode it 90 with no hands because "that's when it happens". Those people I tell they need to find a different shop. At least at that age they heal fast. Also, the first responders won't have to cut off his boots or leather..........

-

I have to agree with Great White that the opportunities are better down South except maybe in the Harley world. I'm not 100% sure, but I believe the Harley shop near me does a decent winter business installing accessories, performance enhancements and top end rebuilds (which seems to be a regular maintenance item in the Harley world). In my shop we do 90% of our business in just seven months. February is pretty slow..........

-

While the very basics of the engine are the same between car/light truck and motorcycle there are some differences. Probably 90% of the bikes on the road are carbureted, and I wouldn't be surprised if they never even mention a carburetor in an auto shop class. Some other things that are quite a bit different: Wheel mounting Clutch Chain or belt drive line on many motorcycles Suspension Engine/transmission generally being a single assembly outside the Harley world The shift mechanism is different on a motorcycle Engine assembly is an entirely different process Most auto engines have self adjusting valve trains where most motorcycles require some form of manual check and adjustment. That's all without even mentioning snowmobiles and ATVs which tend to also go through a motorcycle repair shop. Having said all that, a reasonably bright person with basic mechanical skills can pick it up by reading service manuals and doing. He'd be well advised to visit some service managers in the area and find out what credentials he'd need to get in the door as some sort of assistant.

-

Gas Mileage Question

MiCarl replied to Chaharly's topic in Venture and Venture Royale Tech Talk ('83 - '93)

When I replaced my holey diaphragms my mileage dropped, which makes sense. Those holes let in extra air and cause the fuel metering rods to open less - leaning it out a bit. I put in a Skydoc kit and my mileage went to 40. Low range response was a bit lacking until it was well warmed up and it ran a little hotter than I was used to. I added a 0.020" washer to lift each metering rod. That improved throttle response, reduced the temperature and didn't hurt the mileage. -

I think Trader makes a good suggestion. Problem is everyone needs to cooperate and that would never happen. Besides, I'll be there are not a large percentage that have any idea how to present a link in a post. Look at how much trouble Don has herding advertisements into the classifieds......

-

Pulled the "barb" out of the fuel cock ....

MiCarl replied to Mad Dog's topic in Royal Star Venture Tech Talk ('99 - '13)

I agree with the others. This happens fairly regularly in my shop. We just tap them back in and never had a problem. -

Thanks for the offer, but I still have the new control that was complaining about low voltage from the old transformer. Besides, if you send me parts your furnace will probably need them tomorrow. The first replacement transformer was definitely bad. After I pulled it off the furnace I tested it on the bench - with 146V at the primary I was only getting 15V on the secondary. I'm not sure how much line voltage variation is normal. It's possible my HF multi-meter reads high. I have a fancy power conditioner on the home theater with a voltage meter that currently reads 126V. That with 120 on the other leg would give me the 246 I see at the furnace and in the garage. Everything else we own seems to work just fine. I'm skeptical the transformer was the problem but they're inexpensive and easy to replace so I thought I'd cover that base. If it acts up again I'll see how the new control likes the new transformer.

-

An update: In the process of trying to correct the low voltage fault at the replacement control I cleaned up all the connections. Still the control complained of low voltage -> I believe it was doing that with the gas valves disconnected so it was only the spark drawing power. After discussions with the manufacturer we decided the control was bad and I started the exchange process. All while waiting for the exchange the furnace continued to operate properly. When the replacement control arrived I decided to wait until it crapped out again or spring to put the new control on. It worked fine until spring and I put the replacement control on. THE REPLACEMENT CONTROL FAULTED OUT WITH A LOW VOLTAGE STATUS! I decided the controls I'm buying are junk (it was under $100) and just put it on a shelf figuring if the furnace worked that long I was set. This week the furnace crapped out again. Lit it manually a couple times and it's been fine since. I decided to throw a new transformer at it. The original was 40VA but a humidifier has been added, so I decided to go BIG. I drove 40 miles round trip to pick up a 75VA transformer. The new transformer was only doing 15V with no load connected. Another 40 mile trip and I've got one that shows 27V (my line voltage is 246). So far it hasn't acted up, but it might take another year before it fails again anyhow.