-

Posts

60 -

Joined

-

Last visited

-

Days Won

7

InfinitySurf last won the day on January 8 2025

InfinitySurf had the most liked content!

Reputation

42 ExcellentPersonal Information

-

Name

Drew D

location

-

Location

Lake Norman

Converted

-

City

Denver

Converted

-

State/Province

NC

Converted

-

Home Country

United States

Converted

-

Bike Year and Model

2012 Royal Star Venture S

Occupation

-

Occupation

GC

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

Very nice write-up! I sent my leaking shock to Dave in 2021 when I bought my 2012 RSV and its been great ever since. Been in the back of my mind that at some point I may have to replace the o-ring in the future since I plan to keep my bike long-term, so appreciate the detailed write up being available here.

-

SECOND GEN. S.S. BRAKE AND CLUTCH UPGRADE LINE SET!

InfinitySurf replied to skydoc_17's topic in Member Vendors

Hi @skydoc_17 I am interested in a set of these for my 2012 RSV when possible & also sent you a message. I see these were listed in 2023, so hopefully you still have some available. Thank you & look forward to hearing back from you! -

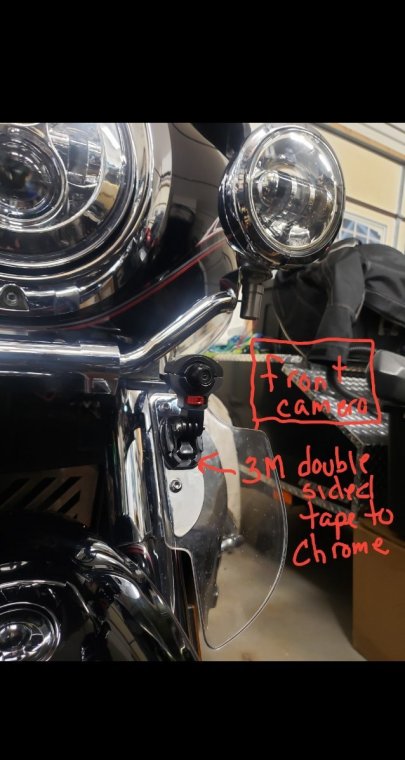

2nd gen - front & rear camera DVR system

InfinitySurf replied to InfinitySurf's topic in GPS, Audio, Electronics

Sure thing. I will paste the links below: Keep in mind that I did some dremel mods to some of this and where the "toothed" pieces join together because I was mating 2 of the same kind (with three teeth and built in nut....on the aluminum ones I drill out one of the nuts so I could use a screw and on the plastic base one I cut off the tooth with the nut. Also because of that they dont mate up perfectly flush so I added a couple thin washers between the mounts so when I screwed it tight they didnt break. If that doesnt make sense I can post a couple more close up pics of those areas if you end up getting similar set up. Another thing, the part that clamps onto the tube or the camera was a slick plastic that was not real grippy so I also added either a real thin piece of rubber or a piece of this 1 sided adhesive grip tape like you put one the floor to help hold a rug in place. This made them clamp on real secure so I should not have to adjust them often since the bike vibration may want to move them over time....figured one I know for sure I like the placement then I also plan to go back and use blue locktight on all the screws that go into the aluminum clamps since I am guessing over time those may also want to back out a little bit. 1x) This is the one I used at the back to connect to the tubing under the luggage pack... https://www.amazon.com/dp/B0D149HB3J?ref=ppx_yo2ov_dt_b_fed_asin_title&th=1 2x) I used 2 of these to hold the cameras... 1 at front and 1 at rear. https://www.amazon.com/dp/B0D142YW5J?ref=ppx_yo2ov_dt_b_fed_asin_title 2 pack) Connected one of these to the above mounts that hold the cameras https://www.amazon.com/dp/B0CPJ5MDTR?ref=ppx_yo2ov_dt_b_fed_asin_title On the below link... I already had these but the helmet mounts like this come in slightly curved mount for helmets or the flat mount (the mount is rounded on the sides), the flat is the one I used to stick to the chrome part of the trim: https://www.amazon.com/Sametop-Adhesive-Accessory-Compatible-Insta360/dp/B0CR1FZLDY/ref=sxin_16_sbv_search_btf?content-id=amzn1.sym.7032aefd-3c59-4a1e-aaf4-8d3a944207a4%3Aamzn1.sym.7032aefd-3c59-4a1e-aaf4-8d3a944207a4&crid=22GU68HQJMMLV&cv_ct_cx=go+pro+adhesive+mount+flat&keywords=go+pro+adhesive+mount+flat&pd_rd_i=B0CR1FZLDY&pd_rd_r=ba5cde73-68cd-4501-bb9c-fd74f8fcd50f&pd_rd_w=HksOC&pd_rd_wg=ljJvb&pf_rd_p=7032aefd-3c59-4a1e-aaf4-8d3a944207a4&pf_rd_r=KD2JJ5KMVTRBH4GKMWBG&qid=1736352891&sbo=RZvfv%2F%2FHxDF%2BO5021pAnSA%3D%3D&sprefix=go+pro+adhesive+mount+flat%2Caps%2C111&sr=1-1-5190daf0-67e3-427c-bea6-c72c1df98776 -

I actually installed this camera system on my bike in 2022 but the camera's came with crappy plastic mounts and it didnt take long for the cheap plastic mounting tabs to break off... then I used some go-pro mounts to secure them but because they were also plastic it didnt take long for them to break as well due to vibration and other normal riding conditions. So I ended up literally electrical taping both camera's to the bike, ugly but in fairly hidden areas so wasnt seen much, been on my to-do list to figure out a better way and just havent done anything till about 2 weeks ago I remembered it still needed to be done and ordered a variety of go pro style mounts made from aluminum that would hold a round object that was 7/8" since both the bullet camera and many of the bikes round tubing is 7/8". Got the stuff a few days ago and nothing wanted to go together like I had planned in my head since by the time I attached 2 pieces that would hold onto both the tube and the camera it was so stinking long that there was no way to mount it on the front that IMO didnt look like crap. So got a little creative and used a mount on the front that uses adhesive and stuck that to my front fork wind guard and then did some dremel work on the piece that snaps into that base since both it and the one that holds my camera are designed to have an adapter between them (which was too long for my liking). I think it turned out pretty sweet. On the rear I used the double 7/8" clamps, attached it too one of the support bars under the luggage box and angled it up as far as I could so the camera just peaks out below the extra light bar that I added under my rear luggage box. The camera DVR system I have automatically starts recording 24/7 and re-writes over old video once its full. Think I have a 256mg micro SD card in there so it will hold something like 24hrs of footage before it starts re-writing. I figure these days its kindof important to have camera's since so many crazy fools on the road. Have them in my vehicles as well including my kids. No long ago I was in line in my truck waiting to turn left...the green arrow turned on and cars started moving, I was maybe 15 cars back from the front...we are all moving when suddenly a lady in the right lane (straight only) stomped on her gas and swerved left in front of the car in front of my clipping her front bumper while doing it. Lady in front of me locked up her brakes... I did the same but could not stop as fast as her small cadillac and just tapped her rear door. No damage to my bumper but put a dent in hers. The Lady that caused the accident was stopped by red light luckily so I ran up there and asked her if she realized she had just caused an accident and also hit the lady in front of me. She got very angry, said she definately hit no one and also didnt cause the accident and that I could shove it. Soon as the light turned green she floored it and took off...but not before I got pics of her, her vehicle and license plate. Anyway the moral of the story, my dash cam in my truck caught everything and the lady was charged with hit and run, etc. Had I not had that footage, because I was the last person in the accident and rear ended the lady in front of me, insurance would have automatically ruled me 100% in the fault. Anyway, got off track there but lot of decent camera systems out there that are not that expensive and can easily be hooked up to power and only gotta do the extra work to hide the wires, etc if you are OCD like me :-). Attached a few pics of how I connected the front/rear cameras to the bike

-

Started on valve cover gasket replacement process

InfinitySurf replied to InfinitySurf's topic in Watering Hole

It was a great opportunity to get the bike nice & cleaned up again. Carb sync is done and after that I ran all the fuel out of the carbs so I don't have to worry about issues there in the Spring. I have her put too bed for a few weeks till I have time to get all the remaining AIS equipment removed & still planning to replace the front wheel bearings & seals before Spring just so its done since that should be quick n easy to do. Have already cleaned/re-packed the new bearings with Lucas synthetic marine grease, have always had good experiences using this grease in my trailers and other stuff. -

That is a great idea, I will most definitely try that! Did you literally just pressure fit them on or are they secured on there with anything? I got the carbs synced and since its so damn cold right now I just put 4 nipple caps on to the intake boots and then also just temporarily capped both of the small hoses for now. Have my heated garage tied up with a quad engine re-build right now so will get back to this bike sometime soon and if I can cap them at the cylinders with the 1/2" copper cap like you showed I will delete every bit of the AIS crap on & under the bike. Thank you for sharing!!

-

Started on valve cover gasket replacement process

InfinitySurf replied to InfinitySurf's topic in Watering Hole

Speakers all replaced. Back together and all good to go, just need to get carb sync done at some point when there is a nice day! -

I read that thread here and saw linking them mentioned in a couple other places, the comments about the idle being wonky after doing that kept me from going that route. I just finished my list of maintenance items on the RSV for this winter and have my bike back together with everything running perfectly again, so planning to sync the carbs on the next day where I have decent weather. Figured after doing that I would go ahead and cap the other 2 nipples. Guess I also need to remove those 2 hoses and cap them where they terminate into the AIS system. The rear hose will be pretty easy to access but that front hose looks like its gonna be a PITA to get too since it terminates between the radiation and the bottom front of the engine. I may end up just plugging that front hose for now so I can get all 4 nipples capped.

-

Happy New Year!

-

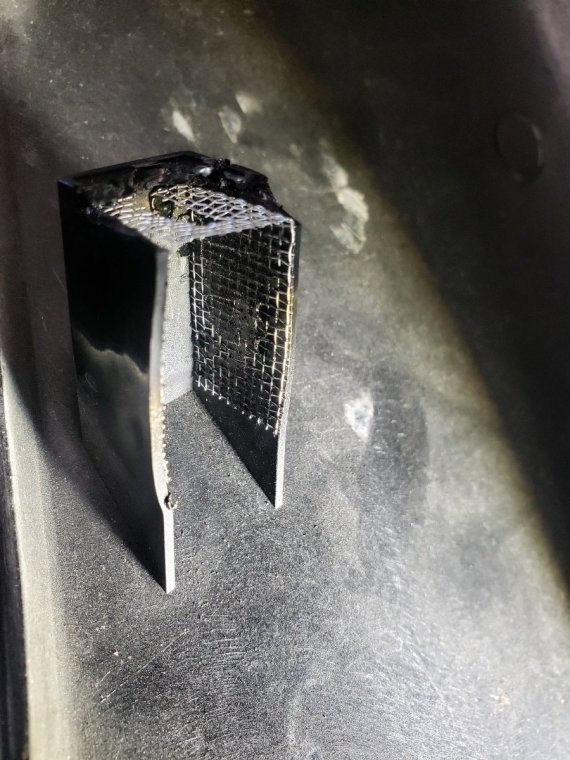

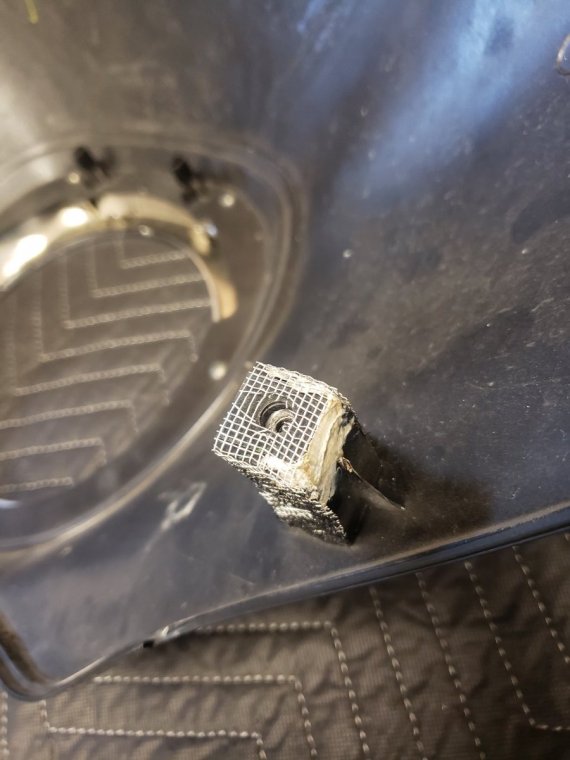

Cold weather so been in maintenance mode on my RSV, so got another write-up for some plastic welding repairs I just did to 3 broken tabs...previous owner had put locktight on the 8 bolts that detach the front fairing/batwing for some reason and when I removed the bolts for 1st time back in 2021, 2 of plastic tabs cracked since they have the metal tabs that clip onto the ABS plastic which is fairly thin. Recently 1 of the center tabs to the front "batwing" broke off completely and the other one had cracks in the plastic tab where it attached to the metal clip so it would have broken off soon too (have before & after pics of this repair). Then on the lower left front cowling that protects your knees, the top tab had cracked when the bike fell over on its side one day while I was having a dumb moment, I didn't notice how bad it was then I guess but when I removed all the body panels to do all my recent maintenance, the entire tab column had snapped off flush with the body panel when I removed that bolt...just thankful all the pieces where still there so I could repair it! I didn't get a before picture of that one but have 4 after pics. That one was actually the most involved repair cause I had to re-attach the entire tab to the cowling. Several different ways you can repair/weld plastic but I have a Polyvance MiniWeld Model 7 airless plastic welder that I have used for a bunch of other repairs in the past since myself and almost all my family members all ride quads and duel sport bikes, so plenty of crashes and broken plastics happen when having off-road fun! This plastic welder has saved thousands over the years by being able to repair vs buying new plastics, been a great investment. On the front fairing/batwing, I decided to do a combination of plastic welding & JB cold welding since the plastic was broken and the metal clip had no plastic between it to hold it in place. Since plastic wont secure well to metal I ended up cutting up strips of metal screen, formed it into a U shape and melted it into the plastic both on the inside and the outside of the plastic tab column so the screen supported the metal tab both under and over it...then I used JB cold weld to weld the metal screen to the bottom and the top of the metal tab with extra underneath it on the sides to add additional support. I used some ABS plastic to weld over the areas where I melted the screen into the tab to help strengthen those areas. Its cured and re-installed on the bike now, feels totally solid so we will see if it holds up long term. On the lower front cowling, I cut a bunch of strips of metal screen, held the broken tab in correct orientation and then started melting the screen into the plastic. I did a crapload of metal screen strips on that one since there are ridges/supports around that entire tab and I wanted it to be super solid. After the screen was all melted into place I used plastic strips called fiberflex (works on many different types of plastic) & welded that over all the screen strips. Looks pretty ugly looking at the repair on the inside of the cowling but you would never know it was repaired from the outside and I bet its stronger now than it ever was. The last 4 pics are of this repair.

- 1 reply

-

- 1

-

-

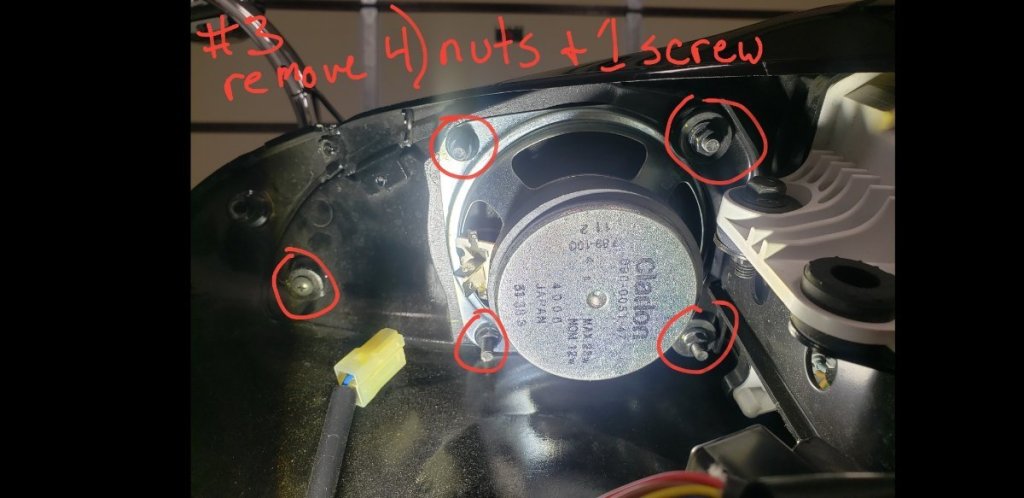

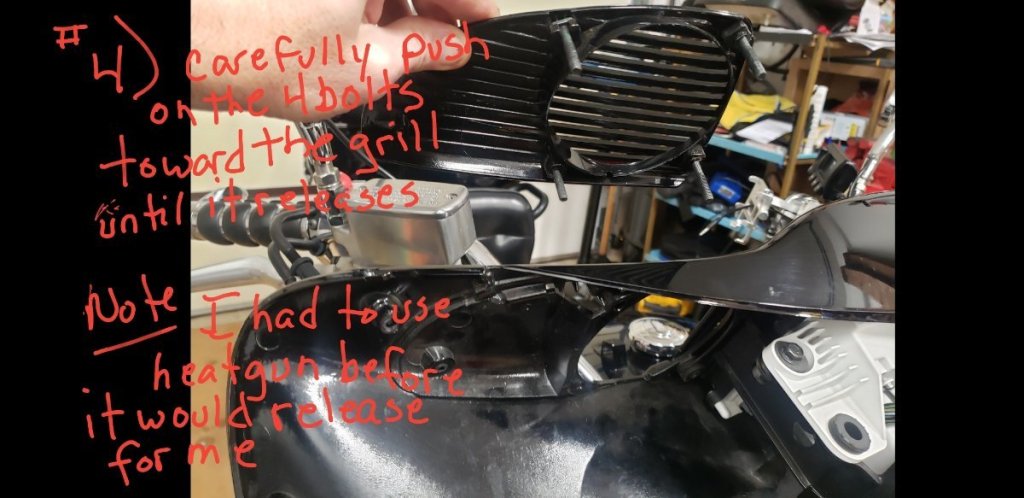

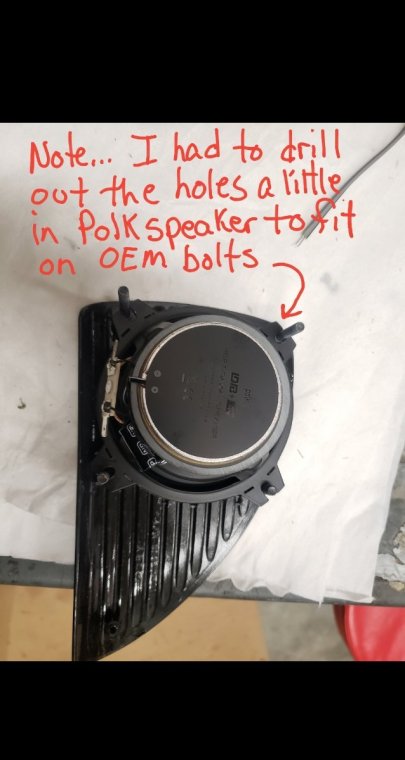

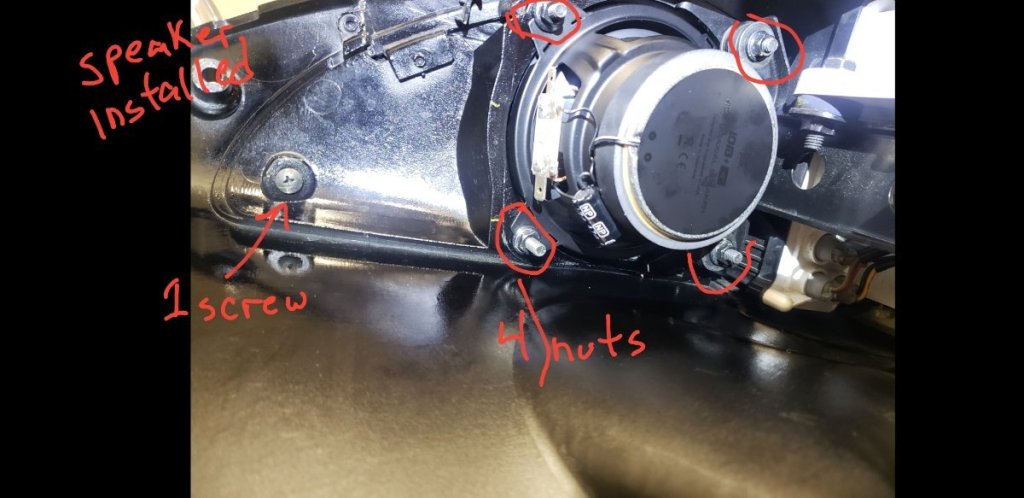

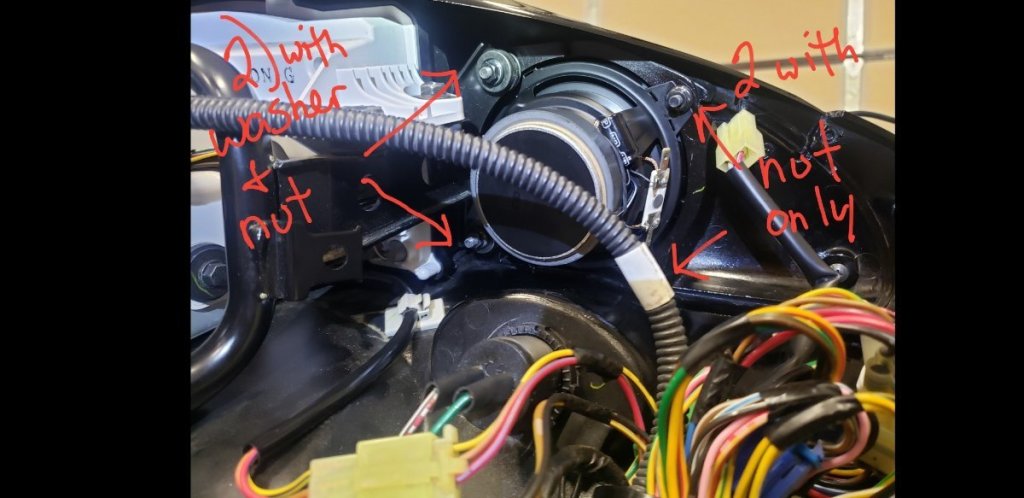

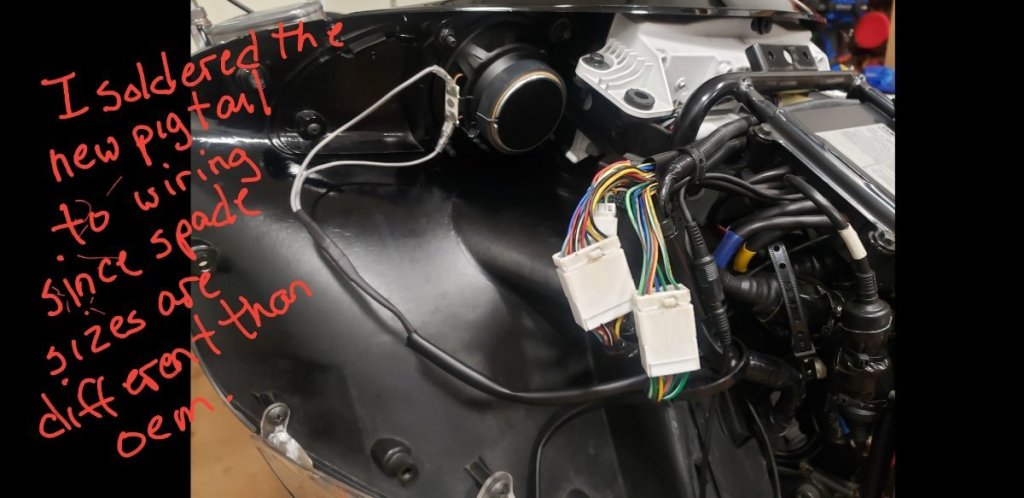

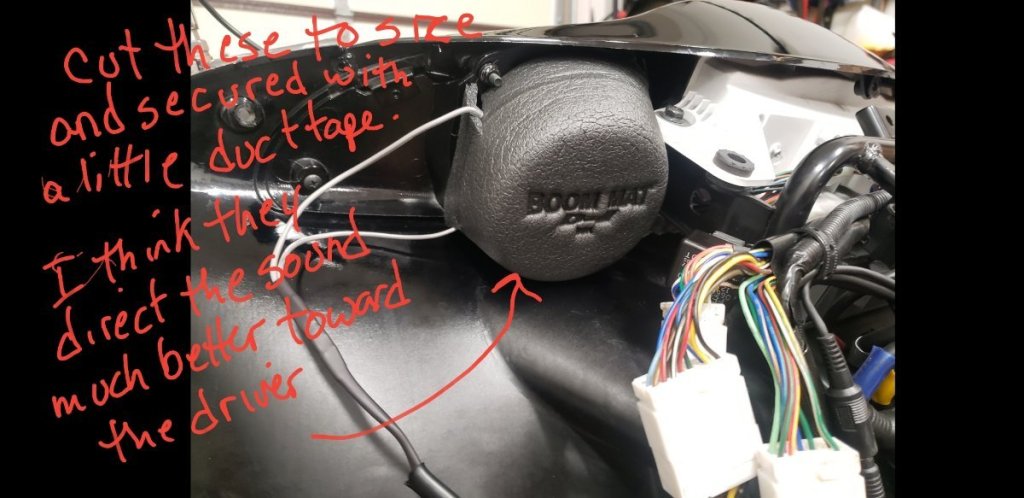

I decided to just go ahead and get the front speakers replaced today and just finished a little while ago. I did realize earlier when searching that someone else did do a front speaker replacement write up back in 2007, there may be others but that is the only write-up I stumbled upon. Figured I would go ahead and post this info anyway since I said I would do it. I used the Polk DB402 and also installed foam baffles (boom mats). After the install was done I tested it for a while without the baffles and then with the baffles. With the front fairing off it makes a HUGE difference having the foam baffles installed, before it projected the sound everywhere and with the baffles installed, when sitting in the saddle the tunes were deeper and projected right at me so IMO, well worth also installing them. I did have to trim the flanges off the baffles since its so tight behind the fairing but a little gorilla duct tape to keep them in place and I doubt they will move. Basically similar to how I installed the baffles for the rear speakers yesterday. The pictures all have notes written on them so pretty self-explanatory but 1 thing to note is after I removed the 4 nuts and the philips head screw that attach the speaker and the grille, nothing wanted to budge with some gentle prodding, being afraid I may break something (since that fairing has proved to be a little brittle at times... actually I have to plastic weld 1 of the 8) tabs back onto the front fairing that broke off when I was removing the screw earlier this evening).... anyway I used my heat gun to slowly heat up around the speaker area and blew some heat thru the grille from the saddle side of the bike, obviously being careful not to get anything to hot....and then all it took was pushing gently on the 4 bolts a little at a time and the grille with the bolts popped right out pretty easily. Like the rear speakers, the OEM connector obviously wont work and the existing spades are much too large for these Polk speakers, I wanted a nice tight connection that I wont have to worry about so since the Polk speakers come with about a 12" pigtail with the correct size spades on one end, I cut the factory connector off and took about 6" of the Polk pigtail wires, twisted the wiring together and then soldered them and put heat shrink tubing over the soldered splices. Hopefully the pics with notes are clear, hopefully this helps someone else down the road. Cheers

-

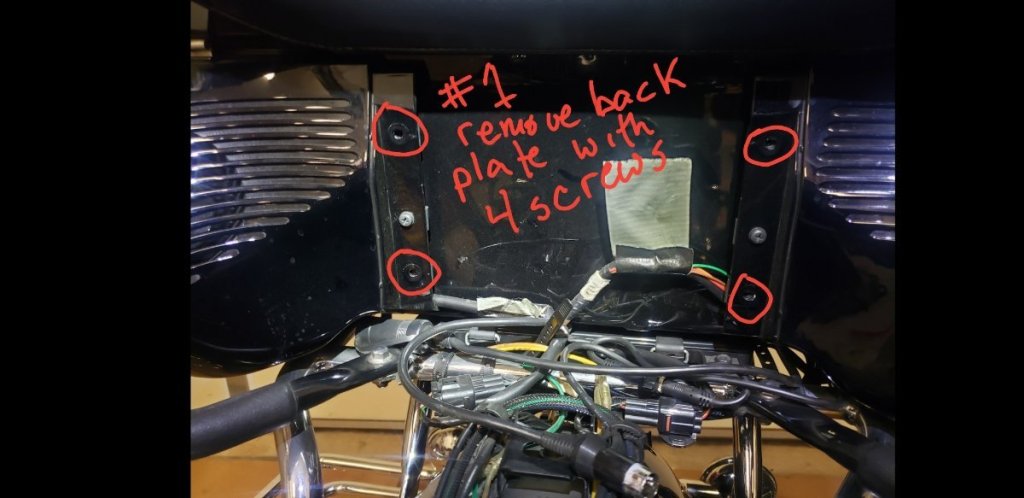

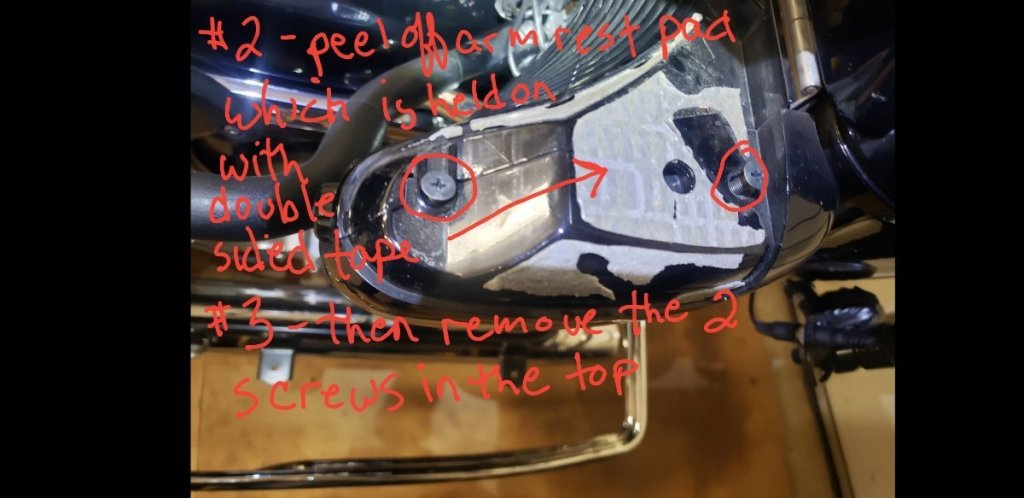

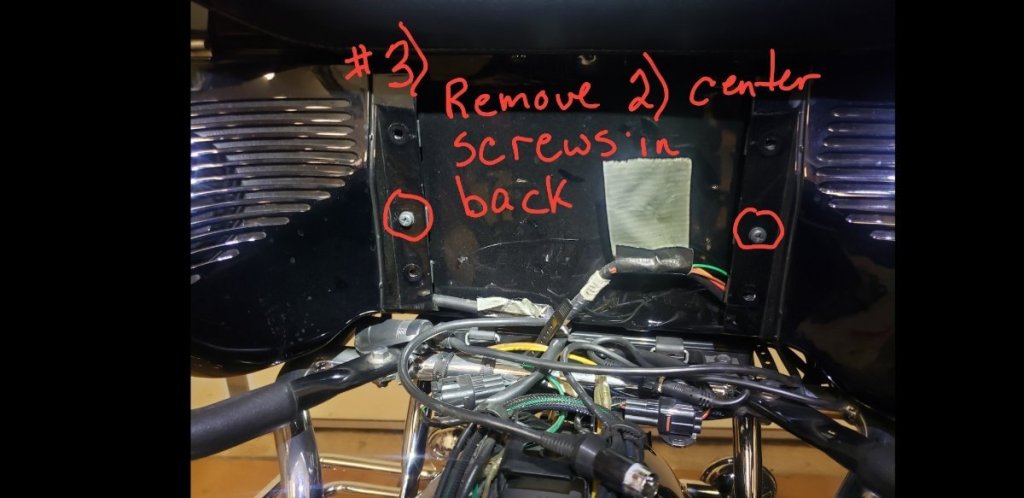

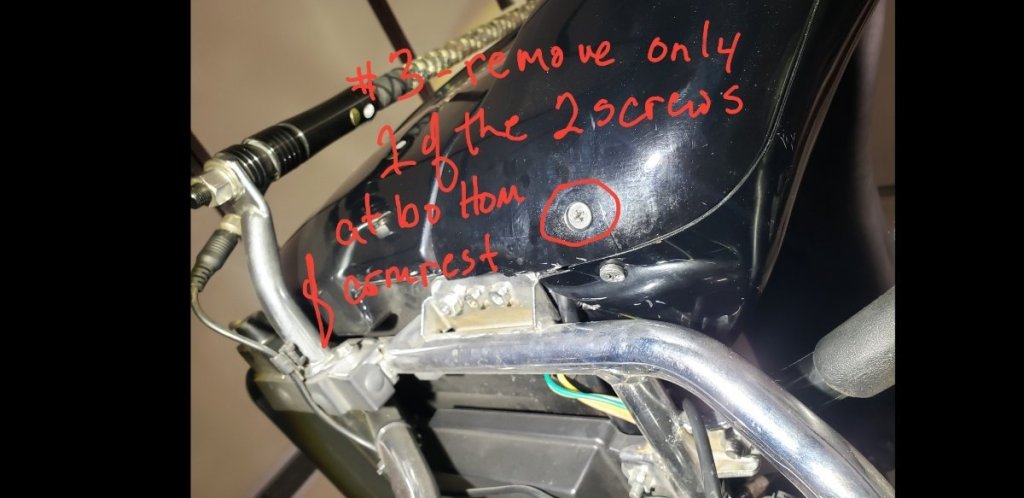

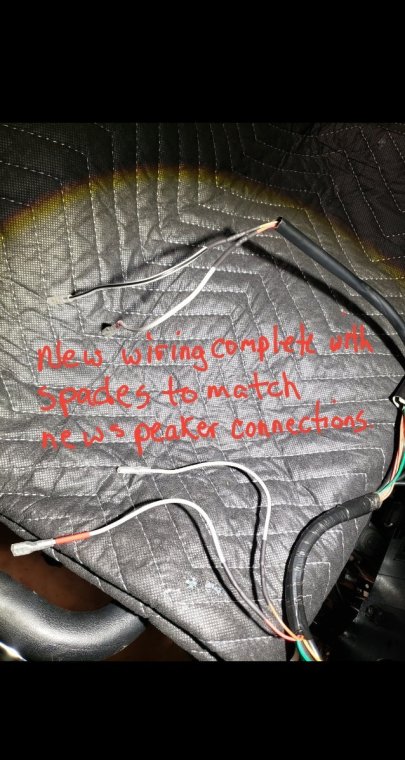

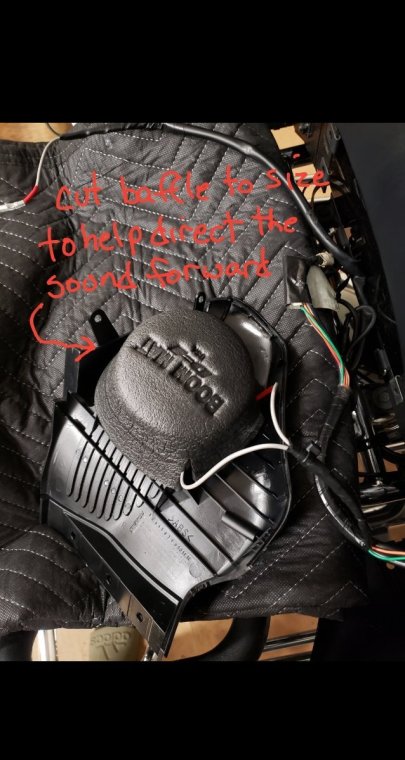

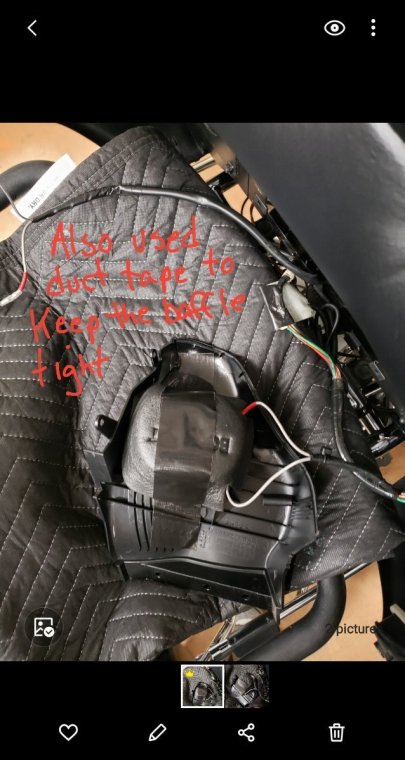

Figured I would post this since I didnt find anything that showed exactly what to do in order to replace the speakers at the rear of the 2nd gen Royal Star Venture - mine is a 2012. I got the Polk DB402 speakers since many have said good things about them and I found a great deal on 4 of them as I also intend to replace the front speakers sometime soon. I am not planning to install an amp at this time, I typically play music thru the AUX cable using my phone. Attaching a bunch of pictures with notes written on them of the process of removing, re-wiring for the different connectors needed and then re-install. Hopefully this is helpful to others in the future. You 1st have to peel off the armrest pad which is held down with a thin double sided adhesive... I heated it up slightly and then carefully pulled them off. Then remove the 4 screws in the rear center cover that passenger leans against. Then to remove the plastic housing on each side which the speaker is connected too there are 4 screws to remove, note that all 4 screws are different so you may wanna label where each one goes. There are 2 screws at the top which are under the armrest pad. There is 1 screw at center rear where passenger leans against...and at the bottom there are 2 screws but you only remove 1 of the 2. Initially I removed 1 and then started to remove the 2nd not realizing that there is a small metal bracket that is held in place with those 2 screws so once you remove 1 of the 2... the other is just gonna spin the bracket which runs risk of breaking something so only remove 1 of the 2. The OEM Clarion speaker has different connectors than the new Polk DB402 so I removed the spades from the connector... and since the Polk speakers come with wiring pigtail that has the properly sized spades I cut the old spades off the OEM wiring and then soldered the pigtail to the OEM wiring. The OEM speaker is disconnected with 4 nuts BUT it was also held to the plastic housing with some sort of adhesive that didnt wanna release, since I didnt wanna risk breaking the housing, I used a heat gun to heat that area up around the OEM speaker and then it pulled loose pretty easy. The Polk speakers have the same bolt pattern so it was easy to push the tabs onto the existing bolts and then re-install the nuts. I has some foam baffles but being pretty tight back there I cut them down some and cut slits in the foam where the wiring connects to the speakers and then used some duct tape to hold the baffle down tight to the back of the speaker so it would direct as much of the sound forward as possible. Speakers sounded really good after the install and seems well worth the cost. I will likely add an amp down the road but not something I am planning to do at this time. Will get the front speakers replaced at some point this winter and will also do a similar write-up when I do that. Happy Holidays!

- 1 reply

-

- 2

-

-

Started on valve cover gasket replacement process

InfinitySurf replied to InfinitySurf's topic in Watering Hole

Got it all back together to start it up earlier... started & ran real good once I dialed in the idle setting properly. Still misting and wet from all the rain here so after letting it warm up good I only drove it about a mile thru the neighborhood and it ran good so super stoked about that! Since in neighborhood it was only 1st gear with 2nd gear only in lower rpm's...only thing I noticed that may require some tuning was in 2nd gear at the lower rpm it "burbled" a bit when I twisted the throttle good, almmost sounded like it was running a little rich. Probably easily tuned out using the air/fuel mix screws. I know all the carb boots and air filter system is tight with no leaks but also gonna double check the exhaust flanges to be sure I dont have any air leaks there since I suppose that could also cause something like that, those short y-pipes are not the easiest to get on/off since you gotta flex them together for them to fit smoothly so hopefully I didnt bogger up either of those seals at all. What is the easiest way to check for air leaks there, spray bottle with soapy water? Gonna get my carb tune out and make sure all the carbs are synced well and then take a break to work on some other projects once I get it all running perfectly and know for sure I wont have to work on it once riding weather comes back. Last thing on my to-do list for this bike is to install 4) new DB402 polk speakers for the front/rear tho it will likely be a few weeks before I get back to that . Thanks for anyone who helped me thru this with comment/advice! -

Started on valve cover gasket replacement process

InfinitySurf replied to InfinitySurf's topic in Watering Hole

Got the new vacuum slide diaphragms installed last night & then re-installed the carbs, airboxes & fuel tank for a quick run test. Been raining for the last few days so fired it up inside the garage for about 30seconds just to confirm it would run and no more gas going thru overflow hoses. Would run on choke only but I am guessing that is partly because I still haven't yet re-installed the mid y-pipes or the mufflers so zero back pressure. At least now that I know it will run right and that my float heights are likely correct and no more air leaks from the diaphragms (I made sure each diaphragm was air tight by using air compressor to do a short blast thru the carb hole to make sure it would operate the needle slide from air pressure...glad I tested before installing the carbs cause one of them still had a minor air leak after install so I removed, adjusted & re-installed and then re-tested and it was good to go after that). Figure now I can put everything back together to give it a proper test. Since I had all 4 carbs completely apart I probably need to reset the idle and may need to tweak the air/fuel mix screws (assembled them at 3.5 turns out which is where they were set initially and also the starting point that Ivans Performance recommends it be started at after installing his needles & main jets).

.jpg.5f37cd93c48c06459c767c46647b595e.jpg)