-

Posts

97 -

Joined

-

Last visited

-

Days Won

7

Content Type

Profiles

Forums

Gallery

Events

Store

Everything posted by Dutch Navigator

-

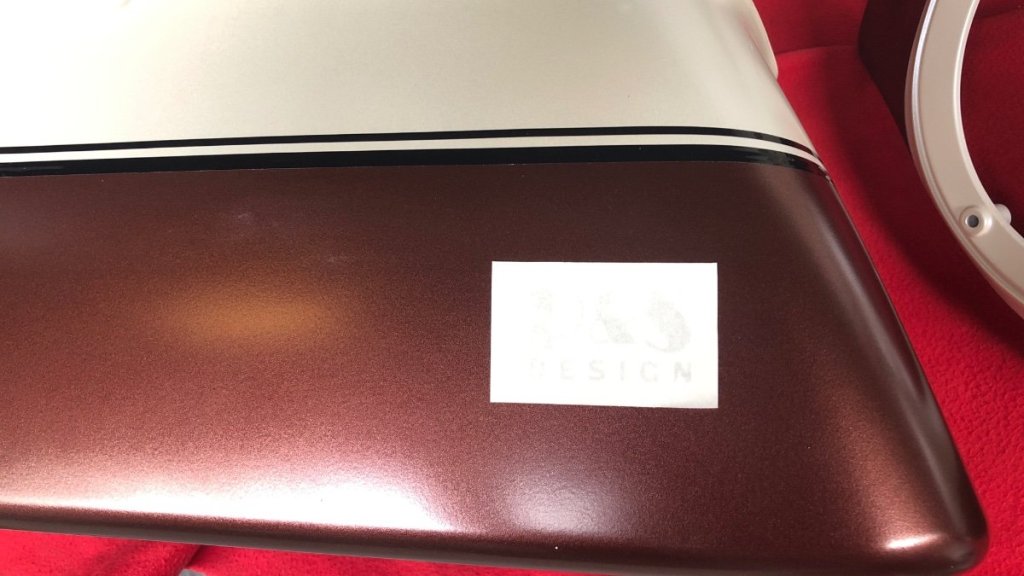

Today the last day in the paint booth. We started at 9am end closed the doors around 5pm. After (again) some problems with the tank, we used an old painters trick: heating up the tank with a heat gun to about 100 degrees Fahrenheit. Then 3 thin layers of paint and between every layer a 4/5 minute pause. In this way there is less chemical reaction because the chemicals evaporate faster. That did the trick! Then the last ivory pearl spray paint. After that we mounted the striping, added our own logo, and prepared all the Tupperware for a couple of high gloss clear coats. The last hour today we used for 3 layers of clear coat. In the last coat we've added 10% thinner so it will create a better flow. Last but not least we cranked up the temperature in de paint booth till about 100 degrees Fahrenheit for two hours.

-

Well, let's be honest. Not everything is going smoothly........... Today in the paint booth we encountered some bad 'crackle' problems with the paint on a fender. Sanding, two thin coats of primer, three thin coats of paint (and 3,5 hours) later the fender was ready for the clear coat. Overall, it was a long and productive day with great results. Clear coat finishes it all!

-

A classic beauty, nice!