-

Posts

11,394 -

Joined

-

Days Won

153

Content Type

Profiles

Forums

Gallery

Events

Store

Everything posted by Marcarl

-

2003 GL 1800. Fork seals were shot. Replaced seals and tubes. One seal still leaked so replaced that one. Found it had turned upside down in the process,, they don't work well that way. So now the new one leaks, tubes are perfect. WHY?

-

Fuel leak at petcock

Marcarl replied to Papa Fred's topic in Royal Star Venture Tech Talk ('99 - '13)

If you have fuel coming out with the petcock off, I would be checking above the petcock real close. Could be that the petcock doesn't shut things off completely, but I would think the petcock seal to the tank?? -

I've never used rainx, but used pledge quite a bit, but it was a Slipstream windshield, but I doubt it was any different. When rain was in the forecast, I would put on a good coating of paste wax . Never a problem. I've heard though that some Rainx will cause problems and that they make a product for 'plastic'.

-

https://www.yamahasportsplaza.com/oemparts/a/yam/500459b6f8700209bc793b3a/exhaust You are right about the numbers, I didn't notice the '1' in the number for the one side.

-

You can try to put some glue in the joint area, but that doesn't always work either and then they are screwed. You can also try to get the diaphragms that have a rubber boot that holds them on, but if your slides come apart it doubtful that will help either. My guess is that the plastic is cracked and therefore the 2 parts won't hold together, so time for new slides. Cracks are very hard to see or find, but logic tells me that something got larger or weaker, and it wouldn't likely be the metal part.

-

2002 royal star midnight venture driver seat

Marcarl replied to maddog2498's topic in Bike Accessories

-

'86 Royale shorted battery

Marcarl replied to Terry NB's topic in Venture and Venture Royale Tech Talk ('83 - '93)

Your memery is not so bad yet, keep up the learnen!! -

Looking for good reports

-

Parts fiche shows the same number, but then it also shows the same number for either side,,, doesn't make sense to me, thought the left side would be opposite the right side. Shows $589 USD

-

When things are over-used, they often have failures,,,,,, just sayin.

-

Somebody likes Canada me tinks, and hey!! it's Canada Day today. Time to celebrate our country.

-

Get a new piece welded on at L&N exhaust. 519-four four nine-5288. Located close to Cathcart Auto Wreckers. May not look as pretty, but will have you up and running soon. Or call Zdeno's in Kitchener, they might have a used one.

-

Weak fuel pump?

Marcarl replied to TTrax's topic in Venture and Venture Royale Tech Talk ('83 - '93)

Depends on what the running voltage is. If the stator is producing 13 some volts when running, then you should be ok for ignition from that point. On the other hand, you might have enough to start, but if the stator isn't producing then you will run into low voltage and then the ignition will start to fail,, but the bike won't start again either. So check the running voltage, it needs to be over 13v. Also, check your battery before you go to bed, it should be 12.6v and then check it again when you get up. No charger attached. It should not be less than 12.5v. If it reads 12.0v then the battery has problems. -

Carl would be good to go, but not the week of the 11th.

-

It's hard to read without any punctuation. You could help us help yourself with a few commas and capitals.

-

Weak fuel pump?

Marcarl replied to TTrax's topic in Venture and Venture Royale Tech Talk ('83 - '93)

Good so far. On the cables going to the carb, the trick is to install the carbs partway, then hook in the cables and then finish pushing the carbs into their seating area, and then push them down on the intake with a little bit of help with WD40 or Fluid Film. FF is better. -

Weak fuel pump?

Marcarl replied to TTrax's topic in Venture and Venture Royale Tech Talk ('83 - '93)

Well I suppose that it is easier to read all the dialogue in one post rather than over time in various posts, but you don't seem to realize that we thrive on helping folks fix things. Now you ticked us off by keeping us in the dark so to speak. What do you think we have all this knowledge base for? All categorized, filed, numbered, and color coded. The best answer I can give at the moment is in file drawer #14, color blue, PW 'asksomemore' . There may also be a copy in other drawers but they can't be opened presently for the case of covid security and border restrictions. Enough BS Hang in there, there will be plenty of suggestions coming your way, this one is super interesting. You have probably missed one dinky little item that needs a half turn adjustment. Couple of thoughts to get you started: When you did the carbs, how far did you tear them done, and did you use new gaskets. Did you check out the enrichment vales as well. Are they seated completely and properly in their boots, check them out again now. Did you clean the idle mixture circuit and how did you adjust it back to spec? Did you check out the stator output. What is your voltage at 5000rpm? Did you check out the grounds, especially the one at the right lower front of the engine? Are the battery terminals clean and tight, also check the terminal to cable connection. Check the fuel line from the pump to the carbs, is there a kink there somewhere. 3psi is not a lot of pressure, but it is spec and should work just fine. Seems like you have or gained a lot of knowledge in your process, Good for you!!! Trouble is, now that you have posted this, it becomes a challenge to some of us, and now you can't get rid of said unit until we get the issue solved or we'll be around to haunt you for decades. -

Good to hear that you got things working again.

-

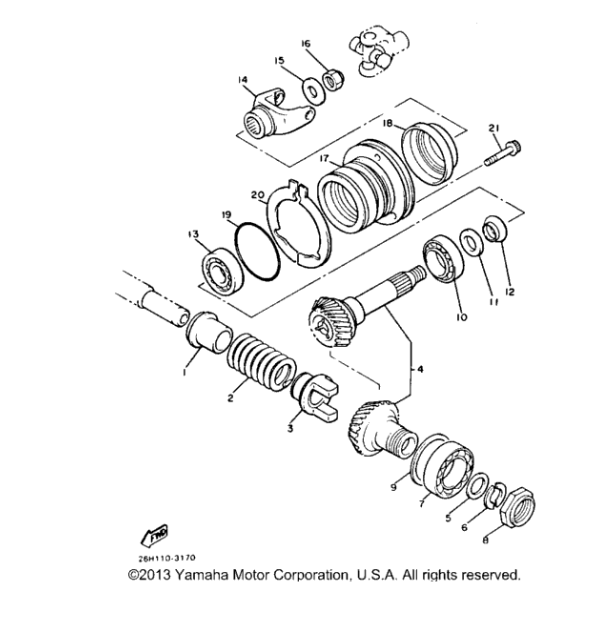

It could be the u-joint at the rear of the transmission #s 14,15,16.. You can pull the boot back to have a peek. Other than that I would suggest it's internal in the tranny, possibly item #4. Try turning the rear wheel and take a listen to the shaft and tranny, see if there is anything noise at all.

-

Yep, put the washer in the wrong spot on the rear axle and what happens is that throws the caliper off and then you could have the issue of the piston not wanting to return easily, heat up and cause a rel drag. The other common issue is a plugged hole in the rear master cylinder which restricts the return of brake fluid after release and then cause heat build up on the caliper and pads and then lockup. It's a wee tiny little hole in the master that might be blocked.