BlueChips84

Expired Membership-

Posts

41 -

Joined

-

Last visited

-

Days Won

1

BlueChips84 last won the day on March 27 2021

BlueChips84 had the most liked content!

Reputation

27 ExcellentPersonal Information

-

Name

Aric Adcock

location

-

Location

ALMONTE, ON, Canada

Converted

-

City

ALMONTE

Converted

-

State/Province

ON

Converted

-

Home Country

Canada

Converted

-

Bike Year and Model

2007 Royal Stad Tour Deluxe

Occupation

-

Occupation

Machinist / University Lab Technician

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

Glad you made it out of that alive! Plan on making her whole again? My one regret is not getting around to riding my gen1 when I had it after restoring it. Ended up with a tour deluxe that took it's place ut I am sure if I rode both back to back I would still still have the gen1😁. Ride safe!

-

I honestly cannot recall the exact facing of the lobes but as long as the intake and exhaust lobes for the cylinder you are checking are either facing toward or away from each other, you should get a good measurement. I shimmed all of mine that were questionable to the top(larger) end of the tolerance as they can generally only get tighter as they seat themselves. If they are in tolerance, I would not bother unless they are right at the bottom of spec.

-

Small update on the leak: since torqueing the bolts to spec, no more oil weeping from the head gaskets at all. I'll make sure to check head bolt torque each time I do shims now since it is so easy to do through the camshaft caps. Now I am just hoping that I don't develop any leaks from the valve cover gasket over time.😒

-

Front Lights Replacement Advice

BlueChips84 replied to Coyote251's topic in Royal Star and Royal Star Tour Deluxe Tech Talk

I'm curious to know as well, always nice to have brighter lights without having to change the whole lamp. I can check the bulbs i have in later today if I remember, they give pretty good visibility on my 2007 RSTD. Will try to report back. Wish I could help a bit more regarding the LEDs. -

Going to look at a 87royal

BlueChips84 replied to Popsnana19655's topic in Royal Star and Royal Star Tour Deluxe Tech Talk

Probably have more luck the the forum for the gen 1's a couple tabs up. -

Seafoam & fluid film on sale at Princess Auto

BlueChips84 replied to saddlebum's topic in Watering Hole

Thanks for the heads-up! I try to run it through the tank every couple of months to keep any build up down. Have a few other things to grab from there for the shop anyhow. -

Always enjoy his videos, very well done. This one really had me eyeing a scout as a smaller, lighter move from my RSTD. Only down side is that the closest Indian dealers to Ottawa are in Toronto and Montreal...

-

I have seen this trick mentioned briefly when doing some researched but the replies were mostly along the lines of it being sketchy or difficult. In fact it works very well and I have used this trick on both my FJ600 and now my RSTD. Use a good thick ziptie and there is no risk of it getting cut by the valve. The method I use is this: 1) Bend a heavy(thick) zip tie to 90 degrees by pinching it with pliers, make sure that the short leg is 1-3/4" long to reach the valve. 2) Turn the engine over until the cams are pushing down the valves and insert the zip tie with the stem facing between the pair of valves you want to check. 3) turn the zip tie gently to one side until you feel light contact or about 20 degrees, then while holding it there, slowly turn over the engine until you feel the valve grab the zip tie. If you miss, try lowering the valve and try again. 4) If you caught it, properly, you can keep turning until you have enough room to pry out the shim from the bucket and grab it with a magnet as usual. 5) when do e, just turn the engine slowly backwards until it let's the zip tie go. Then you can wash, rinse and repeat for the remaining valves. Hope this helps the other cheap buggers like me who don't have the tool handy!

-

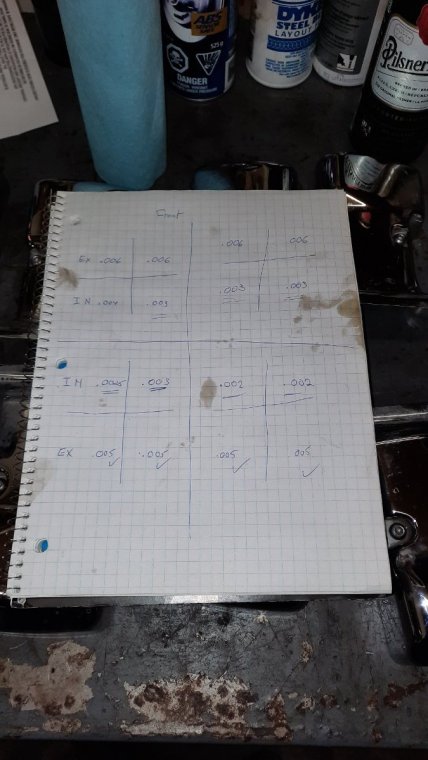

Little update, Turns out that the head bolts can be tightened with the cams in place. Figured this out AFTER pulling the rear cams🙄... Anyhow, pull the rubber plugs on top of the cam caps and then turn the engine slowly until the through holes in the cam shafts line up with the holes in the caps. At this point, you can pass a long 8mm Allen key bit through the hole and start torquing. You'll only be able to do the front or rear cam at a time, so to tighten evenly you should have to turn the engine over a few times by hand. I would say most of the bolts took about 1/4 turn before clicking over but at least 4 took over a half turn after unsticking a bit, I was worried they may be stripped but they did click eventually! Double checked all the bolts again and they all clicked at the proper torque now. Had some fun resetting the timing with all the valve springs fighting me(don't pull cams if you can help it!) But one I figured out the trick it wasn't too bad. Now the next step is to adjust pretty much ALL of my valve shims, I think previous owner set the tighter I stead of looser thinking it would be better. One shim was upside down so I am not thinking it was factory. Below are the measurements found.

-

2007 RSTD cam chain is tight while doing cam removal

BlueChips84 replied to BlueChips84's topic in General Tech Talk

Already had both of those out, still had the chain taught but figured it out. probably caused the initial problem though before I removed the rearmost one. -

2007 RSTD cam chain is tight while doing cam removal

BlueChips84 replied to BlueChips84's topic in General Tech Talk

Never mind, I figured it out! Combination of the valve springs pushing the cam shafts in opposite directions and the loosened chain folding over and binding down in the crank case. Backed if off a bit while taking out the slack and it moved freely after that. Something to be mindful of for anyone playing with the camshafts in the future. Cheers, Aric