-

Posts

839 -

Joined

-

Last visited

-

Days Won

20

Content Type

Profiles

Forums

Gallery

Events

Store

Everything posted by Pasta Burner

-

Pulsating rear 87 VR

Pasta Burner replied to Pasta Burner's topic in Venture and Venture Royale Tech Talk ('83 - '93)

seems I’m doing more work than riding but for sure the washer is between the swing arm and caliper bracket. Changing tires I’m putting it back together as you suggest. -

OEM tires

Pasta Burner replied to Pasta Burner's topic in Venture and Venture Royale Tech Talk ('83 - '93)

That helps determine the tires I’m replacing are from 1997. -

Just curious, what was the OEM tire in an 87 VR?

-

Only took about a half hour to put the front wheel back on, lower and get the exhaust off then get both wheels removed. Much easier to have the jack and not have to disassemble the whole back end. Thanks for noting to do the services while I have the opportunity should only take three beers time to complete.

-

I’m new to having a center stand. I’ve found that getting it off was a bit unnerving at first but am now comfortable. I only have a 30” inseam so straddling the bike is out of the question for me. I do it with the kickstand down and watch my toe placement, give it a good rock back and push heartily forward while turning the wheel to the right. I don’t do it often as right knee surgery keeps me from putting it up unless absolutely necessary. Would love to hear other suggestions

-

what do you mean when you say servicing? Like changing the drive gear oil? Greasing the gears? I looked in the manual both service and owners and in the table of contents rear suspension maintenance and swing arm lubrication are mentioned, but I can’t for the life of me find it in the body of the text. Any advice on how to service the suspension? Are there grease zerks to look for? thanks for the replies.

-

One day a few weeks ago I was just feeling anxious on a ride and many things went through my head that day including tire age. So I decided to look at the actual date code of my tires rather than just checking the tread. Glad I did as they’re obviously pre y2k with only a three digit code. (Dunlop elite 2). I bought the harbor freight motorcycle jack as it’s on sale till the end of the month for $80. Jacked it up last night and pulled the front wheel with minimal issue. Went to pull the rear and now I have to backtrack. (Found a vid on YouTube showing how to remove the rear and that was helpful). But unfortunately my jack placement is completely preventing me from accessing the clamp holding the tailpipe on, so now I have to reinstall the front wheel and lower the bike, remove the exhaust clamp then jack it back up and continue. Anything else I should be looking for before I get ahead of myself again going forward?

-

Glad you got it going. Same story here, some previous owner of mine went through a whole lot more effort bypassing the compressor and adding schrader valves and an auxiliary compressor. They tried to resolder the board, but didn’t know what they were doing obviously. Also had a bridged joint on mine.

-

Bad Stator?

Pasta Burner replied to Schlepporello's topic in Venture and Venture Royale Tech Talk ('83 - '93)

it’s not calibrated but I have more than one so tomorrow I can bounce it against a different one or two. -

Bad Stator?

Pasta Burner replied to Schlepporello's topic in Venture and Venture Royale Tech Talk ('83 - '93)

Good point on other connectors. I’ll give a good scrub to others in line and coat with some dielectric. Battery terminals and cables are clean as can be. I didn’t install the driving lights but I’m almost positive they’re halogen. Will look for an LED replacement bulb as I like the look of the housings the PO installed. meter leads were clamped to the cable, not post. -

Bad Stator?

Pasta Burner replied to Schlepporello's topic in Venture and Venture Royale Tech Talk ('83 - '93)

Well it’s been a few weeks since I did anything, finally got around this evening to soldering the wires and eliminating the connector between the stator and RR. No issues and the wires aren’t even warm let alone burning. I did do some voltage readings with different accessories on and I think a stronger RR would do me well. With the aux driving lights and radio at 2k rpm I was only getting 12.8 return. With no accessories I’m getting 13.3. I’m afraid when I go on a trip and plug in phone, gps, lights, radio...I’ll be draining rather than charging. Thoughts? -

87 Royale Carbs

Pasta Burner replied to Poppa Phill's topic in Venture and Venture Royale Tech Talk ('83 - '93)

With the fuse block conversion, do y’all just still lay it across the battery or mount it somewhere? My OEM is just kinda flopped on top of the battery and held somewhat in place by the battery strap. -

Just another thought...What does the display show when you press the auto settings? Can you toggle between auto and manual? Does the self test work? All characters should show on the display for a few seconds when the key is switched to the acc position. Just checking to see if your display is working correct.

-

When I took my controller apart it was obvious someone previously tried to re-solder the board and didn’t know what they were doing. Some joints were even bridged, but after fixing the superficial defects it still didn’t work. Mine showed all characters on if I remember correct. Anyway I decided to remove and re-solder the entire board. That did the trick. I’m certified to solder and inspect solder and wiring for NASA manned space flight so I have a bit of experience in this realm. I only mention that because even some some joints looked ok to me on the surface. did you run 12v directly to the compressor as I believe Patch suggested? Using test leads from a battery tender is an easy consistent 12v power supply without compromising your battery or having to keep running the bike. You need to make sure the compressor runs before any further troubleshooting. even once I got things responding as they should the compressor wasn’t strong enough to build enough pressure within the specified time and the controller errd out. I took the compressor apart and lubricated the innards with pneumatic tool oil. That did the trick for that issue. also I think I forgot to plug the power harness back in once and scratched my head a few minutes figuring that out. Remember to keep a systems thinking mindset and avoid getting hyper focused on one spot. check that the filters aren’t clogged too. And if the motor seems to want to run but won’t give it a little love tap, not sure of that motor has brushes.

-

1986 venture inspection for newby

Pasta Burner replied to CALEDON's topic in Venture and Venture Royale Tech Talk ('83 - '93)

Good to know. I don’t NEED it right now, just mine are cracked and seeping. Wanted to have new on hand and replace it when I do a valve check. -

1986 venture inspection for newby

Pasta Burner replied to CALEDON's topic in Venture and Venture Royale Tech Talk ('83 - '93)

FYI the head cover gaskets are hard to get right now. Limited shipping due to corona. I’ve tried twice and both orders ended up being cancelled. Also local dealer said it would come eventually but no guarantee on when. -

1986 venture inspection for newby

Pasta Burner replied to CALEDON's topic in Venture and Venture Royale Tech Talk ('83 - '93)

It’s an addictive bike. I’ve only had mine since just before Corona. I bought it just to test the water with a touring bike before making an investment in something new. Gotta say I have no interest in upgrading at this point. you might want to check the CLASS air suspension. Mine wasn’t working when I bought it and if the springs aren’t upgraded you’ll Definitely want some air in there. If it’s working correctly it only operates in the ACC key position and you adjust front and rear separately -

Bad Stator?

Pasta Burner replied to Schlepporello's topic in Venture and Venture Royale Tech Talk ('83 - '93)

Thanks for the update. I was lazy today and didn’t work on anything. Where do the black and red wires come into play? Physically where would I find them? -

Might be a stupid question but you didn’t say you were pressing the high medium or low auto or trying to adjust manually. Just toggling between front and rear will not activate the compressor, only show you the current pressure in the system. also did you re solder the entire board or only what you thought were questionable joints?

-

Bad Stator?

Pasta Burner replied to Schlepporello's topic in Venture and Venture Royale Tech Talk ('83 - '93)

Yes this is the three white wire connector. So your suggesting eliminate the connector? One wire insulation was pretty charred but not to the point of failure. Are you thinking the connector is creating resistance, thus heat? I’ve ohmed out the stator side of the connector and it indicates nominal if that’s what you mean by checking continuity. Micro electronics and wiring is my career so none of what you are saying is foreign to me, just making sure I understand. I’m also an Air Force technical order writer so I’m trained to ask “why?” Haha. Thanks for the assistance. -

Bad Stator?

Pasta Burner replied to Schlepporello's topic in Venture and Venture Royale Tech Talk ('83 - '93)

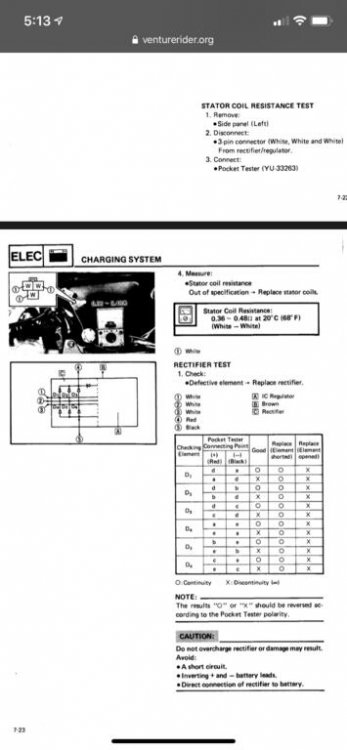

so I can’t make heads or tails of what the service manual wants me to test. Those connections don’t seem to exist. I used the testing method described in this thread https://www.venturerider.org/forum/showthread.php?37884-rectifier-bench-test&highlight=Rectifier+test and everything checks out mostly ok. Using a digital meter in the diode mode two wires consistently measure the same and the other is .003 off. Is that enough to make a difference? Also the connector gets too hot to handle, is that normal? Here is a pic from the service manual, If someone can explain where connection a-e is that might help. As far as I see there are only three white wires. -

Bad Stator?

Pasta Burner replied to Schlepporello's topic in Venture and Venture Royale Tech Talk ('83 - '93)

Thanx for letting me know the service manual has troubleshooting for the charging system. I checked the stator ohms and they were nominal for the spec range. I spent the next two beers searching for the rectifier and thanks to another thread finally found it. Having already showered for the night I’m not laying on the garage floor to do the rest of the tests. I do still have the original fuse block. One of the first things I did was clean and tighten the glass fuses. All are still intact. charged the battery overnight and it charged up full with no faults. Sitting at 12.8v still at the end of the day. -

Bad Stator?

Pasta Burner replied to Schlepporello's topic in Venture and Venture Royale Tech Talk ('83 - '93)

I do not see the vid, might be cause I’m on my phone. A little update, I did the stator tests, ohms at .6; no continuity to ground; voltage with the plug unplugged struck me as odd. With the DVOM set at 20vac with one probe in a terminal read anywhere between 3 and 8 volts. This happened with each wire. As soon as I got the second probe into another socket the volts erred out and had no reading. This was the same for each combination. Plugged the harness back in and was reading 14.2ish vac at 2k rpm if memory serves correct. At idle 900ish rpm each combination was reading between 11.95 and 12.05. The other thing I took note of when doing the tests and on the ride home was that the volt meter drops considerably when the brake is engaged, not sure how much draw the brake lights should have but it was very noticeable. Mind you the battery hadn’t been fully recharged, just thrown on the charger for an hour or so while I finished up work. I pulled the battery in anticipation of needing to replace it, it’s an Apex. I’ve never heard of that brand and can get an Xtreme replacement from batteries and bulbs in stock. Going to take 10 days to get a Deka in but I’m still not convinced the battery is the problem.