-

Posts

13,152 -

Joined

-

Last visited

-

Days Won

7

Content Type

Profiles

Forums

Gallery

Events

Store

Everything posted by Flyinfool

-

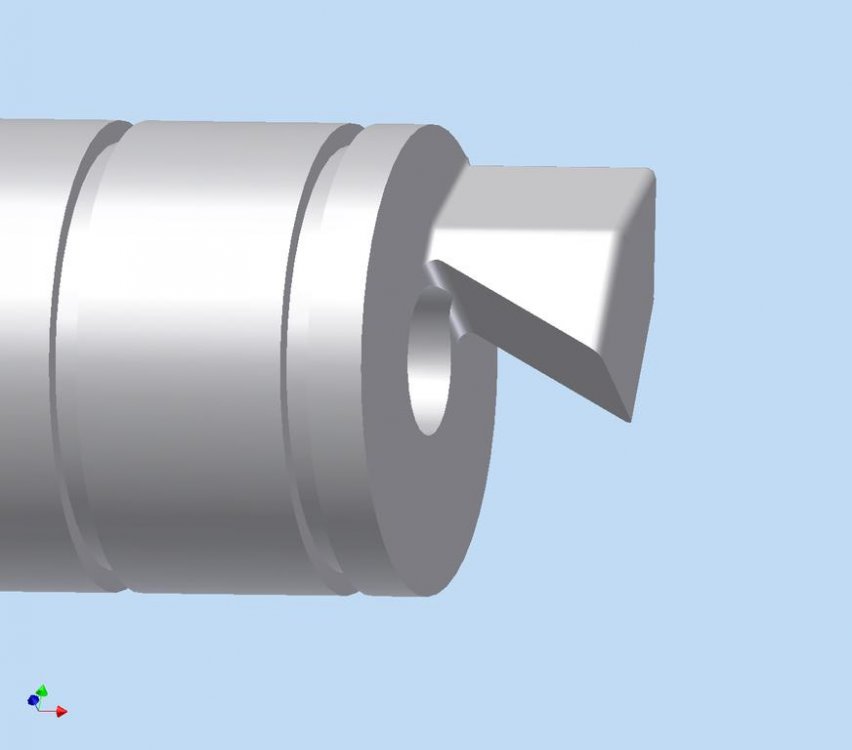

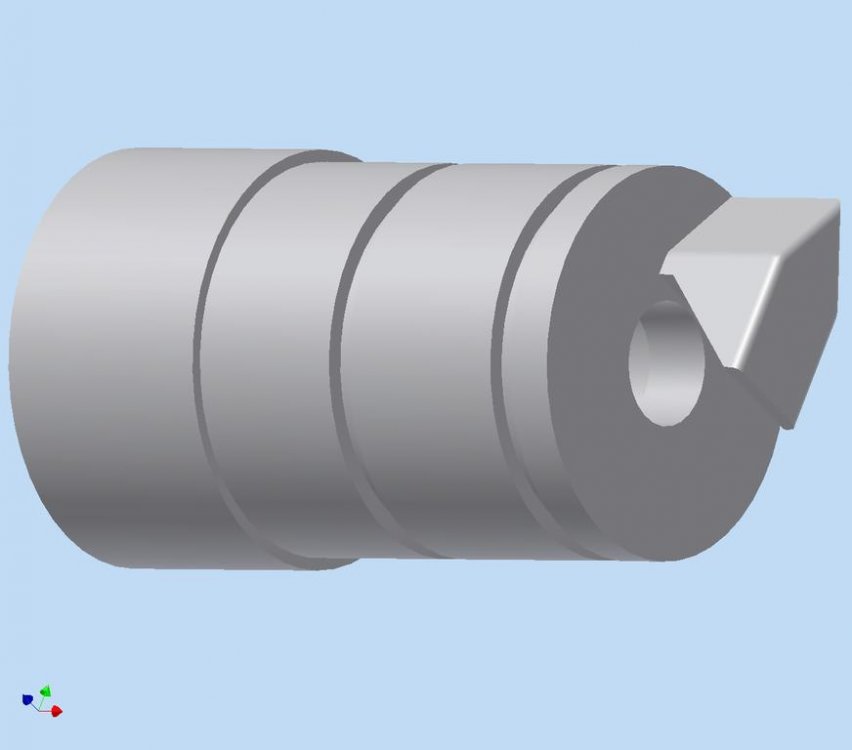

Now look what you did, you got me thinking again, That is ALWAYS dangerous. Just ask @cowpuc. Since I posted that new deflector design I have gone in and added the fillet radii all around the deflector and also changed the deflector angle from 45° to 60°. I already have a 60° dovetail cutter to make that cut. And in thinking about it the 60° angel will also direct the spray more to the center line of the venturi. this should give even less fuel clinging the the carb walls and even better mixing. Maybe? Now I will have to go thru my cutter inventory to see if I actually have a corner rounding end mill in that size and a radius end mill in the right size. BUt if I use my existing dovetail cutter there will be a sharp corner where the deflector meets the body. Just because my cutter is a sharp corner. Hmmmmm........ thinking again........My dovetail cutter is a bit worn, maybe I can take it in for sharpening and at the same time have him knock the corner off to a .03 radius. Sharpening is cheaper than a new cutter. I do have another project coming up soon that will need this cutter to cut a 2 foot long dovetail in steel and the corner radii will not be a bad thing for that one either.

-

I'll try to answer the best I can. 1) The original designer of this system originally did not have the deflector, he could see by looking down the carb that the fuel was spraying onto the opposite wall and clinging there and running down. This caused a significant drop in MPG. When he made new injector holders with the deflectors, The MPG was dramatically improved up to similar numbers of the stock carbs and he could see the fuel bouncing off the deflector and still being in a more atomized condition, Yest there was also some dripping, but at least the drops were starting out in the air stream where other turbulence had a chance to break them up. 2) Actually from modeling I have learned that smooth flow is not always your friend. Adding texture to a wing can make it faster than a smooth wing. At the trailing edge of a wing a square edge will give much better performance than a sharp smooth transition. Of course this all changes with changes in velocity. I suppose I could easily calculate the air velocity thru the carb by knowing the venturi cross sectional area, the max rpm, displacement of the cylinder and then make an guess/assumption on volumetric efficiency. 3) This is an interesting one, An increase in lift always comes as in increase in drag. You can never get any kind of energy for free that energy has to come from somewhere. What is happening on the golf ball or dimpled/textured intake runner or even a wing as I mentioned in #2 , is the uneven surface keeps a layer of turbulence at the surface. air is a fluid, it is sticky and will stick to a smooth surface, the texture while increasing drag to create the turbulent layer has that turbulent layer prevent the flowing air from sticking to the surface and this then reduces drag by more that the drag induced by the turbulence so the result is a net reduction in drag. This is all happening at the molecular level so it is really hard to test for and see with the naked eye. 4) I was not going to be using a timed pulse, it is a batch flow system. Airflow's, velocities, and such should remain very close to what the stock system has since it still using all of the stock parts. There will just not be the slid encroching into the bore creating turbulence, there will just be a tiny deflector living in the bore. 5) I can see where the changes in airspeed thru the venture will create some extra turbulence to assist in the mixing of the fuel and air. it is very possible that the venturi may give a better result than would a straight tube. 6) I can see we are talking about two different things while using the same word LAG. I was referring to the lag/bog of having to wait for everything to stabilize before the engine will even start to make power. If I am correct the lag you are referring to is the same as you would get in an old carbureted car when the accelerator pump goes bad, you mash the gas and the airflow is able to speed up a lot faster than the heavy gas can so there is a LAG in fuel delivery. In a CV carb there is no accelerator pump so the slide with its small ports causes the carb to actually open slower so that the fuel and air can both increase speed at the same rate. With EFI and 60PSI shoving in the fuel you should be able to snap the throttle wide open and the fuel will be forced to match the acceleration. The TPS will tell the computer that you just snapped the throttle wide open so it will know to instantly dump in more gas. As I mentioned earlier, I had redesigned the deflector to further reduce drag. this design helps the air to flow around the deflector while being a lot easier to machine that the rounded end and also making the connection of the deflector to the body a lot stronger. There was one reported instance of a deflector snapping off and being ingested by the engine. That would be a BAD thing. There is nothing that will kill flow faster than a hole in the top of a piston or a chunk of something getting stuck and holding a valve open. I suppose that for even more strength I could make this part out of either a stronger grade of aluminum (I was going to use 6061-T6) like 2024 or 7075, or something other than AL, like Titanium or Stainless steel. All 3 of these options will make machining much more difficult. My design of deflector has 3.2 times the connection area to the rest of the body than the original design and I also eliminated the sharp inside corner at the bottom of the deflector to reduce the stress riser. I may even add a fillet all around the base of the deflector to further reduce stress risers.

-

First off let me make it very clear that I am not an expert on engine fueling and/or breathing. Having been designing aircraft as a hobby for the last 50 years I do know a little bit (not a lot) about aerodynamics. I work as a mechanical engineer so I have some experience in the mechanical part of what makes things work. The only part of that injector holder that is in the air stream is that deflector. Through testing it was determined that the defector worked better than no deflector. I took it a step farther and made my deflector more aerodynamic to help reduce turbulence. The original design of the deflector was just a cube with one side angled for the deflection. I have refined the shape of the defector even more that the one in that pic to further reduce drag and turbulence. Sometimes some turbulence is a good thing. Look at a golf ball or the dimpled intake runners. Not to say all turbulence is a good thing. The injector itself has its nozzle very close to flush with the wall of the venturi. Of course since there is now 60PSI shoving the fuel in there really is no need for a venturi. Yes this is a 4 injector system. I do not see where any additional throttle lag would come from. While I am sure tat this is no where near optimal, it is fast and easy and relatively inexpensive. I think that to get optimal yes it would be best to design a complete new intake system optimized for EFI. It would also be a lot more expensive to make. All of the pumps hoses electronics injectors would be the same for either system, this one just has a couple of custom parts to get it all to work vs a complete new everything. Yes it would be better to have the injector spray straight down the intake like most throttle bodies do. Again it gets to be more involved mechanically to make that happen. This project got started during a time when it seemed every other post was about someone having some kind of hard to track down issue with their CV carbs. As I mentioned early in this post, I hate carbs, They are blue smoke and mirrors, I do not understand what all is going on inside of them or why it is all there in the first place. I am much more comfortable with wires and electronics and programing with a direct if this then that logic flow. I fully understand that this is not a performance upgrade. I never expected it to be. It is just something different than the mysterious carbs that we all have to deal with. If I were after a performance increase I would slap on a set of V-Max heads, cams, and V-Boost. That is a well documented performance upgrade. The best I was hoping for was equal performance to what I had and no more carbs and their problems to deal with. I like designing and making stuff, Fire away with your ideas, I may have to work with you on the final design of parts to fit within my capabilities. I have already had to spent a full week designing and making fixtures and doing machine setup to make a cut that took a few seconds to do. That defector is actually a very hard thing to make with what I have to work with, but that is a BIG part of the fun of it. But alas, I no longer have or can have a bike so my carb issues are also no longer in existence and that is what ended my actively working on this project.

-

Yup, Tow truck drivers have had them for a long time. They do not have to hang wires down the towed vehicle, just hang their self contained light bar on the back.

-

Either the 4 or 5 wire systems are perfectly legal in all states. Some cars and/or trucks are natively 4 wire and some are 5 wire. Some vehicles have a built in 5 to 4 converter and some don't. You will have to check out what you have.

-

Lets talk about Geezer teeth,,, to partial or not to partial?

Flyinfool replied to cowpuc's topic in Watering Hole

Gee and I thought it was robbery because next week I go in for a root canal and crown for just under $900 out the door. My boss has recently gotten several implants, He said for the most part they are great, but the one thing the dentist never mentions is that the tooth on that implant is slightly above the gum line and you do and will get food particles stuck between the tooth and the gum, it is hard to get them out, its not like you can take the tooth out to clean under it. When the tooth is screwed to the implant they use a non toxic form of red Loctite. Just something to ask about while you are getting quotes. -

$4K for a high mileage, rusted out, 20 year old car is not cheap. $4K is about what it would be worth if it did not have any rust and lower mileage. In the pics it looked like most of the holes were in the body mounts. A real PITA to fix. It requires taking the whole body off the frame to be able to get at it to fix it right. As for salt, so far the city has already used 750,000 TONS of the 1 million TONS of salt that they bought for this whole winter. We are in a weather pattern of snow every other day for the foreseeable future. They have already started mixing salt and sand 40-60 to stretch the salt out longer.

-

Not ANY powered converter is fine. You still need to get either a 4 wire or a 5 wire to match your trailer.

-

Seat belts and helmets can not be compared. A helmet does nothing to help you maintain control of the bike and so it also does nothing to protect others on the road. Seat belts on the other hand if worn can and often do make the difference of you still being behind the wheel to at least try to control the vehicle. If you get hit and start into a spin that could launch you out of the drivers seat, you now have zero chance to regain control of the car, or apply the brakes or anything else that might be required to prevent further problems. If you are wearing a set belt you will at least still be there to try to save it. Granted most drivers do not have the skill level to correct a spin or other problem. One of the arguments that I often hear about helmets is that because there are studies that show that with no helmet, you are more likely to have head injuries in addition to all of the other injuries that you sustained and that puts additional financial burden on the idiot that ran the red light and hit you. Of course my answer is that if you are worried about the increased medical cost to you from hitting lidless bikers, THEN STOP RUNNING RED LIGHTS AND STOP SIGNS. Maybe we need to push for all occupants of any vehicle to be required to wear a helmet or show proof of additional insurance. After all even in a car you are safer with a helmet on. Why do ALL race car drivers wear helmets, and look at the strength of their roll cages compared to that of a family car. I mean safety is safety is it not?

-

Sounds like a good deal depending on just what the needed work really is.

-

On the part that hold the injector into the slide bore there is a 45° deflector surface to get the injector spray headed in the correct direction. That 45° surface is an under cut. There are other ways to do it but they would be a lot harder to do, and I would probably break a few tiny 1/16 Dia end mills to get it done. It will work without the deflector, but a lot less efficiently, because the injector spray would just go straight across and want to run down the side of the venturi instead of getting atomized. I do have a 60° dovetail cutter already, not ideal, but it would likely be better than no deflector. As I mentioned earlier in the thread, IF I had CNC this would be a WHOLE lot easier. But I am all manual machines so I have to set up each cut. I am also pretty cheap and do not want to spend the cash to buy a special cutter for the one tiny cut. I was also going to use the mega squirt for this project with the same intention of down the road using the squirt to also control COPs.

-

The scope I sent back to Leopold was a very old scope, but it had a lifetime warranty. Back in the day they made air rifle scopes and rifle scopes. they were not to be switched. All current Leopold scopes can handle either air or BANG. That did not used to be the case. It was my understanding that it was the way the optics were mounted to the tube. They used to only be supported from one side. Modern ones are supported from both sides. I also do not know if that is also true of other manufacturers.

-

The trailers that have separate turn and brake lights use a 5 wire connector. The trailers that have combined turn and brake lights use a 4 wire connector. The bike is wired as a 5 wire, you will need a converter to use 4 wire. It is recommended to use an isolating converter if you need a converter. It is also recommended to use an isolator even if you are going 5 wire. An isolator pulls its power direct from the battery so you are not taxing the bikes wiring and switches with the higher amp draw from the trailer.

-

I found this out when I sent a broken scope back to Leopold. First thing they asked after examining the scope was "Was this on an air rifle" They then explained to me that air rifles create a backwards vibration and the lenses of a rifle scope are not mounted to handle both directions. Leopold does make airgun specific scopes to handle the double recoil in both directions. There are a lot of modern scopes that also will work fine on either rifle or airgun.

-

As far as I know there is just one more expensive cutting tool that I need to acquire to be able to make the parts. I was thinking about trying my hand at making my own cutter, I have never tried that yet. It might just be a fun side project. I even have it partly drawn up in cad. To buy a 45° dovetail cutter that is big enough is very expensive @ $200+ It would cost me around $40 to make one with a carbide insert. [ATTACH=CONFIG]115553[/ATTACH] I have not yet even tried to make the parts out of metal yet, I have only made the plastic parts just to verify my setups and process. This also means that I have no idea if this will actually work. But I no longer have a bike to test on nor anyone local that would be interested in experimenting.

-

As far as I know there is just one more expensive cutting tool that I need to acquire to be able to make the parts. I was thinking about trying my hand at making my own cutter, I have never tried that yet. It might just be a fun side project. I even have it partly drawn up in cad. To buy a 45° dovetail cutter that is big enough is very expensive @ $200+ It would cost me around $40 to make one with a carbide insert. I have not yet even tried to make the parts out of metal yet, I have only made the plastic parts just to verify my setups and process. This also means that I have no idea if this will actually work. But I no longer have a bike to test on nor anyone local that would be interested in experimenting.

-

In some places thay already can stop and frisk just because they want to.

-

I'm in chat allllll alone.........

-

What a way to render a truck nearly useless. But it does look cool

-

Well just for proper closure on this topic. I am now permanently bikeless due to medical stuff. That has pretty much ended this project. If someone wants to pick up where I left off, I would still like to join in to help it along. It was/is a fun project for something that is different.

-

Carbs have always been a compromise at best. They just never seem to be able to have the perfect mixture across their full range. That is alyas why some people tune for top end and some tune for torque and some for HP and some for cruise. That is also why you can not find much of any new vehicle that still has a carb. I was getting close to finishing the design of converting my Venture to EFI so I could have that near perfect air fuel ratio across the board. In order to not mess with the air handling that the engineers so carefully designed into out bike too much. I was going to convert the CV carb into throttle bodies. This way I keep all of the good air handling designed by those that know a whole lot more than I do and just change the way the fuel is metered and added to the air stream. https://www.venturerider.org/forum/showthread.php?128079-EFI-for-the-Ventures I am now permanently bike less due to medical issues so I will never get to finish this project unless someone wants to get in it with me. I was kind of stalled at needing an expensive milling cutter to make one of the cuts on the part the would hold the actual injector. I was getting closer to just making my own cutter. For me the machining is half of the fun. I may have been all wet with my theories But if I am having fun that is half the battle. At least none of the changes that I was making to the carbs were permanent so I could always go back to carbs quickly and easily, don't even have to take them off the bike. To me carbs have always been a lot of blue smoke and mirrors, I have always been more comfortable playing with electrons, they just make more sense to me.

-

That depends on where you buy it. Some stores have very liberal return policies. Something worth asking about.