All Activity

- Last week

-

80 degrees today so we got our chores done and took a ride, about 2 hours of back roads.

-

Asphalt Cowboy started following Hannigan Steer-Lite, EZ-Steer, Rake Kit

-

Good evening to All! We are having rain and a very unstable weather pattern over the course of 10 days...but I see some 70 degree temps coming up.

- Earlier

-

I 'think' he is saying that he just might buy a new ride.

-

Are you saying you are done riding now?

-

No more snow in our area, but winter might just put another round of snow next week and hopefully that would be it for the season. I am so ready for Spring and also thinking that time springs forward on March 8.

-

Been blowing and plowing snow this last week! Also repairing units as things went south! Roads were clear for a few days then Bam snow again! -19cel this morning when I picked up son from work! Got oil and filter the other day now just have to change it!

-

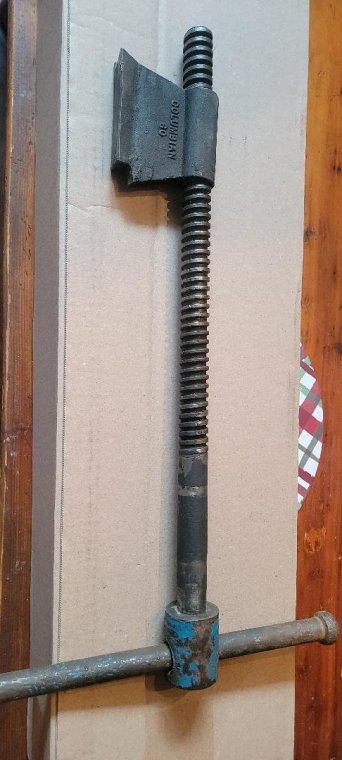

So looking through Mcmasters, they offer carbon steel and alloy steel rods. The alloy is about twice the strength of the carbon, the alloy is more expensive, which is not a problem, but the next question is will I be able to weld the alloy with a simple 6011 rod, ....final pass with a 7018? I don't know if alloy means a different type of weld than the farmer / junkyard welding I typically do for structural fab.

-

So, I talked to a fella with a small shop who will repair it for $600. Not gonna do that. I'll try to talk to another fella tomorrow and if his price is similar I think I'll take Dawsons' advice and drop down from 1 1/8" to 7/8" and replace the rod and the nut. We'll see how it goes.

-

I was thinking the same thing, but the cost of the rod / nut may cost as much as to have a threaded sleeve made up. Better yet would be to have the original part bored and a new threaded sleeve inserted and welded in place. There's a little machine shop nearby. I'll keep the assembly in my work van and stop by and see what they say. I'm guessing a couple hundred $$$...Still worth it for such a beast of a vise.

-

Thinking outside the box here John. I googled 1-1/4 ACME rod and found places to get rods and coupling nuts. Maybe replace the original rod and weld in a coupling nut. Make both sides new instead of matching the old. Or drop down a size if needed and sleeve it.

-

Yup, It's a big-un. That's why I grabbed it but the repair's looking like it may be a problem. I could take it to a machine shop that's capable of cutting an Acme thread, but the expected cost may be worth more than the vise. I'm still exploring options. Thanks for thinkin' of me. 🙂

-

yep that's a lot bigger than the one I have in my shed, I broke the mounting ears off of it but the screw is still good. but it's way to small for what you have.

-

John do have some pictures of this project?

-

Looking at what McMaster-Carr offers and poking around on some machinist websites I find , you are correct that 1/4" or 1" ACME are typically made with 4 threads per inch and 1 1/8" ACME are typically made with 5 threads per inch. I agree with Ronnie, search out a local machinist to verify what you have, It is possible the vice manufacturer made their own proprietary thread form, that is not really an uncommon practice. The other possibility is maybe it is not a true ACME thread form, could a Buttress thread or a square thread, they look similar to ACME and are similar in strength and would be suitable for the lead screw on a vice. Again a half decent machinist would be able to tell you.

-

Got a good machine shop close by? With the industry here our local machine shop has worked with a lot of acme threaded stuff. Somebody like that might can help you.

-

Weird one. I've a very heavy, very large old Columbia vise that I've come across. At OSU, one of their shops was throwing out this old Columbia vise because the threads on the ?nut? were stripped. I've found that they're ACME threads and as I measure the diameter of the rod I get 1 1/8" diameter and count 4 threads per inch. I can repair this by finding a coupling nut that will thread onto the rod, cut off the part that's stripped and weld a coupling nut in it's place. The problem is that I only find 1 1/4" or 1" nuts offered with the 4 threads per inch. 1 1/8" nuts are available in 5 threads per inch only. I wonder if this is actually a 1 1/4 rod that I'm looking at. I haven't taken a micrometer to it, but as it sits it clearly measures 1 1/8" and it sure looks like 4 TPI. I'm measuring at the end and the threads don't appear worn at this point on the rod. Should I expect this rod that measures 1 1/8" is sized small to accommodate the loose fit desired for a vise?

-

Time is up for me sitting on this chair. Will be blowing snow and clearing sidewalks in a few minutes.

-

Got the bike out last week and the bug out a couple days ago and now we are staying in the house in front of the fire place cause it's to cold outside.

-

So we had some snow yesterday and into the overnight. It turns out, it was not as bad as the last one that was coupled with a long deep freeze. Just sitting here at the big desk then will tackle the snow and clear my driveway and sidewalk in a couple of hours. Have a great Monday!

-

It's been awhile since I have seen anyone.

-

Yes sir! I'm not getting too ahead of myself. I'm saving up about 5 grand for a down payment. We're looking at a 2021 plus, low mileage for hopefully less than $20,000. There's a beautiful 2018 with only 8000 miles in Lincoln, and they're only asking $15,999 for it. Really tempted to get that one. The 2021 and up have upgraded audio and a bigger trunk with better rear backrest for the passenger. I'll have graduated with my Associates in Civil Engineering in May and this will be a gift to myself! As for the Venture. Got the tank taken off and rust proof-ed and very happy with the results. Its a decent sized job, but really not too terrible. Looks tougher than it is!

-

valve cover gasket leaking oil on back left side

luvmy40 replied to maddog2498's topic in General Tech Talk

Most likely it's time for new gaskets. Stay away from the chicom gaskets. They will not seal. -

N3FOL started following How is everyone doing with winter

-

Got called in to work this morning and may work well into midnight. We will have lots of snow moving in the area I guess that is why we have so many call outs today. No riding for me this week.

-

Got the convertible out yesterday and just rode around and today it's gonna be cold and windy I think I'll just stay in the house.

.thumb.jpg.bf82ce75721b193880368d3ccb1ca2d0.jpg)